Jul 16 2015

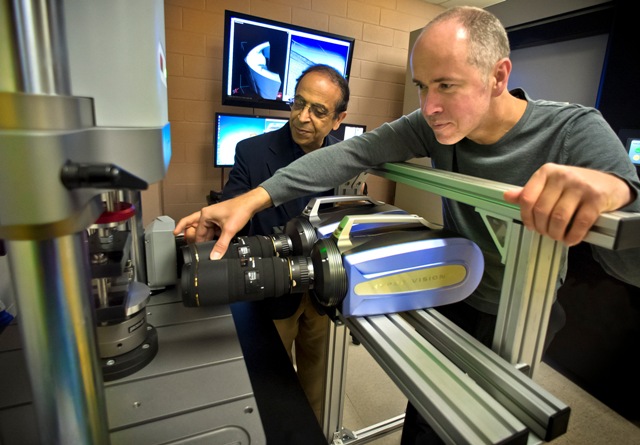

Andrew Makeev, right, professor in the Mechanical and Aerospace Engineering Department and director of the UT Arlington Advanced Materials and Structures Lab, looks over research results with Erian Armanios, chair of the Mechanical and Aerospace Engineering Department.

Andrew Makeev, right, professor in the Mechanical and Aerospace Engineering Department and director of the UT Arlington Advanced Materials and Structures Lab, looks over research results with Erian Armanios, chair of the Mechanical and Aerospace Engineering Department.

A professor from the University of Texas at Arlington (UT Arlington) has received a $1.35 million grant from the Army National Rotorcraft Technology Center to develop advanced composite materials for aircraft applications.

As part of this grant, Andrew Makeev, director of the UT Arlington Advanced Materials and Structures Lab and professor in the Mechanical and Aerospace Engineering Department, has collaborated with Sikorsky Aircraft to design stronger, better, and more durable composite materials and expedite their use in composite aircraft.

This latest endeavor is part of a Vertical Lift Consortium (VLC) Program, Advanced Materials Technology – a joint effort of Boeing, Bell Helicopter, Sikorsky Aircraft, UT Arlington, and Penn State University, which is also under the leadership of Makeev.

A VLC member, Sikorsky specializes in the design, development and service of commercial and military helicopters, civil helicopter operations, fixed-wing aircraft, overhaul and repair services for helicopters, and spare parts and maintenance. The company’s helicopters are utilized in all five branches of the US armed forces, including commercial and military services in 40 counties.

Leveraging the success of the VLC Advanced Material Technology Program, Makeev will develop, test and define innovative configurations and polymeric composite aircraft material applications. Makeev’s laboratory will continue to work with material developers to devise bonding solutions and laminate reinforcement methods in order to reduce weight and enhance the vertical lift aircraft efficiency. Extensive analysis would also be carried out to develop consolidated techniques for sophisticated material qualification which would reduce implementation expenditures for the new, enhanced material systems.

In addition, under the basic research projects sponsored by the Army Vertical Lift Research Center of Excellence and Office of Naval Research, Makeev’s lab has also developed predictive and diagnostic analysis techniques.

“This effort epitomizes our research mission to accelerate the implementation of composites through close collaboration with industry and government labs – a key to achieving cost-effective performance for the next generation of aircraft,” Makeev said. Erian Armanios, chair of the Mechanical and Aerospace Engineering Department, added that the benefits of this latest study could positively affect all aircraft construction in future.

“This project plays a key role in the implementation of composites in both commercial and military vertical lift aircraft,” Armanios said. “The benefits also will impact fixed-wing aircraft such as the Boeing's 787 Dreamliner which has 50 percent composites and Airbus A 350 with 53 percent composites.”

VLC is a national organization including academic institutions and the U.S. rotorcraft industry that are involved in vertical lift aircraft studies, with an aim to provide long-term development of rotorcraft. The communications committee of the consortium chose UT Arlington as the VLC Member of the Month for June. The University was honored to contribute towards the development of predictive and diagnostic tools for composite materials.