The first laboratory-based diffraction contrast tomography (DCT) system for 3D grain imaging was launched today by Carl Zeiss X-ray Microscopy, a pioneer in bringing synchrotron imaging capabilities to the researcher's laboratory.

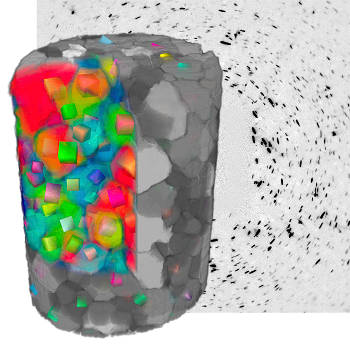

Direct visualization of a beta-Ti alloy (~300 um diameter cylinder) with overlaid 3D crystallographic information reconstructed from diffraction patterns showing reflections of over 500 grains simultaneously

Direct visualization of a beta-Ti alloy (~300 um diameter cylinder) with overlaid 3D crystallographic information reconstructed from diffraction patterns showing reflections of over 500 grains simultaneously

The LabDCT™ advanced imaging module enables a handshake between theoretical and practical worlds for predictive materials design by visualizing grain orientations in 3D. Originally developed at a limited number of synchrotron X-ray facilities, this marks the first commercial offering of DCT on a laboratory X-ray microscope (XRM).

Non-destructive Characterization

LabDCT non-destructively obtains 3D crystallographic information from polycrystalline samples. Combining grain orientation information with microstructural features such as cracks, porosity, and inclusions opens new possibilities for characterization of damage, deformation and growth mechanisms related to 3D materials science. Imaging these microscopic features in three dimensions with advanced contrast techniques enhances the collective understanding of fundamental materials mechanisms behind these processes.

Henning Friis Poulsen, Professor of Physics at the Technical University of Denmark, said, "Since its development more than a decade ago at synchrotron sources, demand for DCT has steadily increased. Making DCT widely available via laboratory-based systems promises to fuel materials science research efforts, taking it from proof-of-concept to detailed studies of microstructural controlled materials phenomena."

4D and In Situ Studies

Exposing samples to in situ sample environments within the microscope, or to an extended time evolution "4D" experiment (across days, weeks, months), is a unique strength of laboratory-based XRM experiments compared to the synchrotron. LabDCT extends the ability of 4D and in situ microstructure evolution studies to explore the influence of crystallography on materials microstructures in a laboratory tomography instrument for the first time.

Philip Withers, Professor of Materials Science and Director of the Manchester Henry Moseley X-ray Imaging Facility, noted, "LabDCT represents a major step towards addressing the grand multi-scale challenge in 3D materials science. By providing non-destructive 3D information about the grain orientations and morphologies, LabDCT promises to deepen our understanding of microstructure-property relationships and accelerate the development of micromechanical models for a variety of materials degradation and deformation processes."

Correlative Microscopy

Following a 4D evolution experiment, possible only through a non-destructive imaging process, a sample may be sent to the electron microscope or focused ion beam (FIB-SEM) microscope for complementary high-resolution post-mortem investigation such as EDS or EBSD of identified volumes of interest. Such correlative workflows, efficiently enabled by the ZEISS Atlas 5 platform, point to the future of modern microscopy and seamlessly leverage the multi-modal, multi-scale and multi-dimensional characterization platforms provided by ZEISS.

Synchrotron-quality in the Lab

According to Dr. Kevin Fahey, Senior Vice President, Global Marketing and Market Segments for ZEISS Microscopy, "The ability to do 4D experiments in one's own lab that allow you to observe grain growth and microstructural evolution in real systems enables researchers to expand their range of materials systems study, and to study evolution like corrosion over time. This represents another example in a long legacy at Carl Zeiss X-ray Microscopy of bringing synchrotron-quality X-ray imaging to the laboratory."

Availability

LabDCT is immediately available as an optional module for the ZEISS Xradia 520 Versa 3D X-ray microscope. LabDCT includes GrainMapper3D analysis software developed by Xnovo Technology ApS.