A research initiative led by scientists from Stanford University and the Department of Energy’s SLAC National Accelerator Laboratory reveals the motion of individual atoms at a speed of trillionths of a second, creating wrinkles on a material that is three atoms thick.

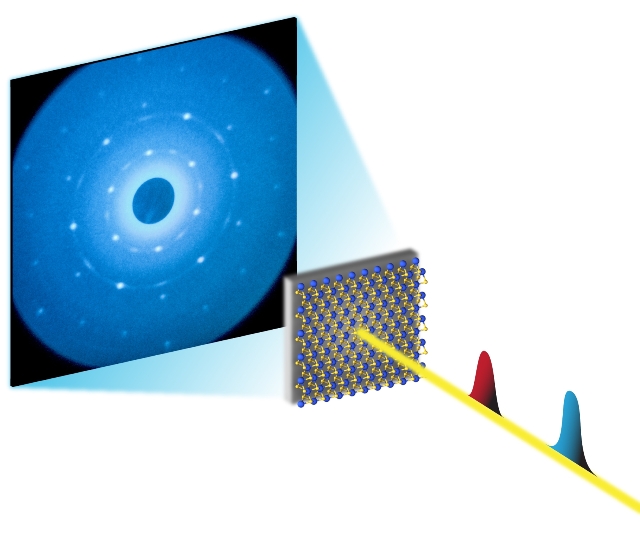

To study ultrafast atomic motions in a single layer of molybdenum disulfide, researchers followed a pump-probe approach: They excited motions with a laser pulse (pump pulse, red) and probed the laser-induced structural changes with a subsequent electron pulse (probe pulse, blue). The electrons of the probe pulse scatter off the monolayer’s atoms (blue and yellow spheres) and form a scattering pattern on the detector – a signal the team used to determine the monolayer structure. By recording patterns at different time delays between the pump and probe pulses, the scientists were able to determine how the atomic structure of the molybdenum disulfide film changed over time. (SLAC National Accelerator Laboratory)

To study ultrafast atomic motions in a single layer of molybdenum disulfide, researchers followed a pump-probe approach: They excited motions with a laser pulse (pump pulse, red) and probed the laser-induced structural changes with a subsequent electron pulse (probe pulse, blue). The electrons of the probe pulse scatter off the monolayer’s atoms (blue and yellow spheres) and form a scattering pattern on the detector – a signal the team used to determine the monolayer structure. By recording patterns at different time delays between the pump and probe pulses, the scientists were able to determine how the atomic structure of the molybdenum disulfide film changed over time. (SLAC National Accelerator Laboratory)

The motion of the atoms was captured by a new “electron camera”, which is one of the fastest electron cameras in the world. Such a high level of detail, never achieved before, could be useful guidance for researchers in the development of high-performance chemical catalysts, efficient solar cells, and fast and flexible electronics.

The research findings have been approved for publication in Nano Letters on August 31st. This revolutionary finding elevates materials science to a new level. This research used SLAC’s instrument for ultrafast electron diffraction (UED), which employs energetic electrons to take a snapshot of molecules and atoms at the rate of 100 quadrillionths of a second.

“This is the first published scientific result with our new instrument,” said scientist Xijie Wang, SLAC’s UED team lead. “It showcases the method’s outstanding combination of atomic resolution, speed and sensitivity.”

SLAC Director Chi-Chang Kao said, “Together with complementary data from SLAC’s X-ray laser Linac Coherent Light Source, UED creates unprecedented opportunities for ultrafast science in a broad range of disciplines, from materials science to chemistry to the biosciences.” LCLS is a DOE Office of Science User Facility.

Ultrafast Electron Diffraction: How It Works

Remarkable Material Properties in 2D

2D materials, also known as monolayers, consist of only one molecular layer. This structure enables them to exhibit exotic properties, such as exceptional electric and heat conductivity and high mechanical strength. Till date, researchers have not been able to fully explore the fundamental mechanisms that cause these unique characteristics.

“The functionality of 2D materials critically depends on how their atoms move,” said SLAC and Stanford researcher Aaron Lindenberg, who led the research team. “However, no one has ever been able to study these motions on the atomic level and in real time before. Our results are an important step toward engineering next-generation devices from single-layer materials.”

Molybdenum disulfide (MoS2) was the material studied in this experiment. This material is a commonly used lubricant that exhibits a number of unique characteristics in its monolayer form, which is over 150,000 times thinner than a single strand of human hair.

The monolayer in its normal form is an insulator, but when it is stretched, it is transformed into an electrical conductor. This changing behaviour can be utilized in encoding the information contained in data storage devices and in thin, flexible electronics. The possibility of using thin monolayer films of MoS2 as catalysts in chemical reactions is also being explored. Apart from their conductivity, they are efficient in capturing light, making them potential materials for use in solar cells. Based on their ability to capture light, scientists are looking at ways to manipulate the properties of the material using light pulses.

“To engineer future devices, control them with light and create new properties through systematic modifications, we first need to understand the structural transformations of monolayers on the atomic level,” said Stanford researcher Ehren Mannebach, the study’s lead author.

Electron Camera Helps Visualize Ultrafast Motions

Past analysis of monolayers of molybdenum disulfide revealed that they have a wrinkled surface, but this was based on a static picture. This new research shows the formation and development of surface ripples when a laser light is incident on the material.

The monolayer samples that were prepared by Linyou Cao’s group at North Carolina State University were placed in the path of highly energetic electrons. These electrons, which were packed in ultrashort pulses, scattered the atoms of the sample, thus generating a signal on the detector. Researchers referred to this signal to locate the position of atoms in the monolayer. This method is known as ultrafast electron diffraction. After the signal was detected, the team used ultrashort laser pulses that excited motion in the material, causing the scattering pattern to change with time.

“Combined with theoretical calculations, these data show how the light pulses generate wrinkles that have large amplitudes – more than 15 percent of the layer’s thickness – and develop extremely quickly, in about a trillionth of a second. This is the first time someone has visualized these ultrafast atomic motions,” Lindenberg said.

After gaining a complete understanding of the monolayers of various materials, scientists could start combining them to fabricate new mixed materials. These mixed materials would exhibit entirely new electronic, mechanical, optical and chemical properties. The SLAC UED/UEM program development fund, DOE’s Office of Science, U.S. National Science Foundation, and the German National Academy of Sciences supported the research work.