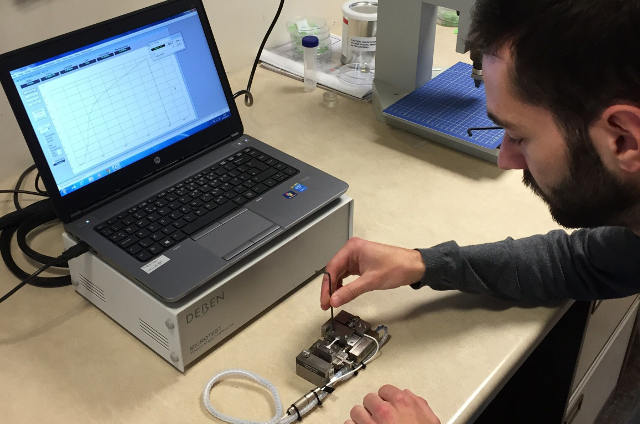

Deben, a leading provider of in-situ testing stages together with innovative accessories and components for electron microscopy, reports on the use of the Microtest 200 N tensile stage in the Department of Aeronautics at Imperial College, London, where it is used to measure load displacement curves on nanocellulose-reinforced polymer composites.

Dr Koon-Yang Lee is a Lecturer in Composite Manufacturing in the Department of Aeronautics at Imperial College London. His young and dynamic research group focuses on the manufacturing of polymer (nano)composites, surface and interface engineering, particle stabilised emulsions and foams.

His research is highly multi-disciplinary, with an emphasis on the development and manufacturing of novel polymer composite materials with a focus on tailoring the interface between two (or more) phases to bridge the gap between chemistry, physics, mathematics, materials science and engineering.

They apply green engineering principles to produce environmental friendly, biodegradable and high performance materials for various high volume structural and semi-structural applications. The area of focus here is on the characterisation of nanocellulose-reinforced polymer composites.

These are designed to have mechanical performance that exceeds commonly used engineering materials. Their use includes high volume structural and semi-structural applications.

Asked why he chose to use the Microtest 200 N stage from Deben for his research, Dr Lee said:

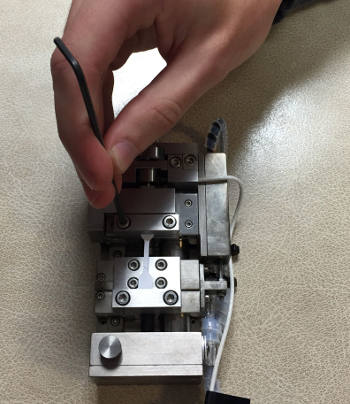

“The sample size that we can produce is small for early-stage materials exploration. The Deben stage works perfectly in this context as it can be used to test small dog bone specimens and the load cell is well designed for the range of loads cellulose nanopapers and nanocellulose-reinforced polymer composites. The load-displacement curves obtained have better resolution than other stages that I have used. Deben also provides good customer support, from the training of using the testing stage to debugging any problems encountered.”

To obtain full details of the Deben applications and product portfolio, please visit www.deben.co.uk.

About Deben

Deben are a UK precision engineering company specialising in the field of in-situ tensile testing, motion control and specimen cooling for microscopy applications. Established in 1986 and named after a Suffolk river, Deben now operate from a large, modern business unit in Woolpit near Bury St. Edmunds in Suffolk.

The product groups are motor control systems, in-situ micro-tensile stages, Peltier heating & cooling stages, detectors for SEMs and electro-static beam blankers. The company also makes custom and OEM versions of these products to specifically meet customer requirements.

Deben provide consultancy, design and prototype manufacturing services. In house facilities include SolidWorks and SolidEdge 3D CAD and COSMOS finite element analysis software, CNC machining, electronics design and manufacture and software design using Visual C++, Microsoft.net and DirectX. Utilising these resources and experience, Deben manufacture products for OEMs and end users in the UK and overseas.

Deben UK Ltd. is a subsidiary company of UK based Judges Scientific plc. For details on Deben and all its products & solutions, visit www.deben.co.uk.