Feb 13 2017

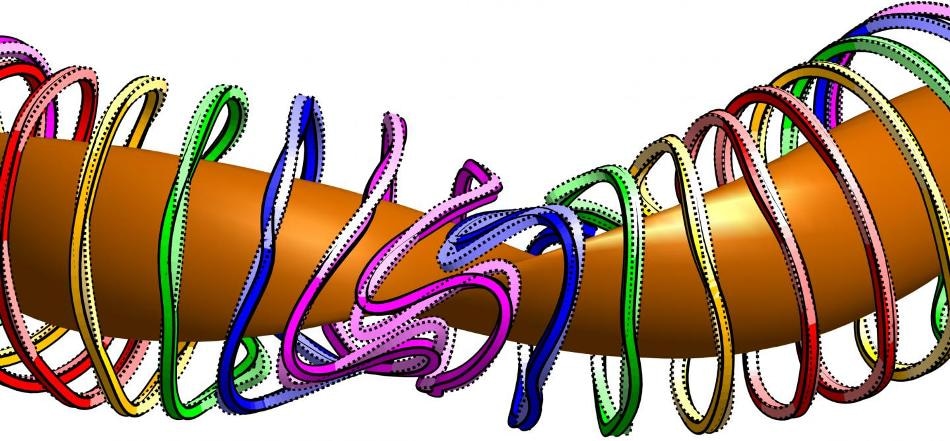

Fusion experiments known as stellarators work by confining a mass of superheated plasma (orange horizontal mass) inside a magnetic field generated by external electromagnetic coils (multicolored vertical bands). A UMD physicist has made a revision to the software tools used to design these complex coil shapes, allowing researchers to create better designs with more room between the coils for repairs and instrumentation. The solid lines denote shapes made by the old software, while the dotted lines denote shapes made by the new software. CREDIT: Matt Landreman

Fusion experiments known as stellarators work by confining a mass of superheated plasma (orange horizontal mass) inside a magnetic field generated by external electromagnetic coils (multicolored vertical bands). A UMD physicist has made a revision to the software tools used to design these complex coil shapes, allowing researchers to create better designs with more room between the coils for repairs and instrumentation. The solid lines denote shapes made by the old software, while the dotted lines denote shapes made by the new software. CREDIT: Matt Landreman

An old carpenter's proverb, "Measure twice, cut once", highlights the fact that cautious planning will help save materials and time in the future.

This concept also seems to be ideal for the design of stellarators, which are complex nuclear fusion experiments that help explore the potential of fusion as an energy source. Stellarators function by confining a ring of blazing-hot plasma inside an accurately shaped magnetic field produced by external electromagnetic coils.

Atomic nuclei begin to fuse together, releasing increasing amounts of energy, when the plasma gets to several million degrees that is almost as hot as the inside of the sun.

Engineers first use a series of algorithms to develop exacting plans even before turning a single bolt to construct one of these costly and rare devices. However, a wide range of coil shapes can all produce the same magnetic field, generating levels of difficulty to the design process. Until now, few researchers have examined how to select the most appropriate among all potential coil shapes for a particular stellarator.

Matt Landreman, physicist from the University of Maryland, made a vital revision to one of the most familiar software tools used to design stellarators. This new method is considered to be better at balancing tradeoffs between the potential coil shapes and the perfect magnetic field shape, resulting in designs with increased space between the coils. This additional space enables easy access for repairs and more places to install sensors. The February 13th issue of Nuclear Fusion describes Landreman's new method.

Instead of optimizing only the magnetic field shape, this new method considers the complexity of the coil shapes simultaneously. So there is a bit of a tradeoff. It's a bit like buying a car. You might want the cheapest car, but you also want the safest car. Both features can be at odds with each other, so you have to find a way to meet in the middle.

Matt Landreman, Physicist, University of Maryland

The method called Neumann Solver for Fields Produced by External Coils (NESCOIL), first described in 1987, was used by researchers to design several of the stellarators that are currently used, including the Wendelstein 7-X (W7-X). W7-X, the largest stellarator in existence, started its operation in 2015 at the Max Planck Institute of Plasma Physics, Germany.

"Most designs, including W7-X, started with a specifically shaped magnetic field to confine the plasma well. Then the designers shaped the coils to create this magnetic field," Landreman explained. "But this method typically required a lot of trial-and-error with the coil design tools to avoid coils coming too close together, making them infeasible to build, or leaving too little space to access the plasma chamber for maintenance."

Regularized NESCOIL, also known as REGCOIL, is Landreman's new method that gets around this by tackling the coil spacing problem of stellarator design in tandem with the shaping of the magnetic field itself. Landreman stated that the result is a much more robust, fast process that produces enhanced coil shapes on the first attempt itself.

Modeling tests carried out by Landreman suggest that the designs developed by REGCOIL confine hot plasma in a specific shape, while majorly increasing the minimum distances between coils.

In mathematics, we'd call stellarator coil design an 'ill-posed problem,' meaning there are a lot of potential solutions. Finding the best solution is highly dependent on posing the problem in the right way. REGCOIL does exactly that by simplifying coil shapes in a way that the problem can be solved very efficiently.

Matt Landreman, Physicist, University of Maryland

The development of nuclear fusion as a practical energy source seems to be far off into the future. However, innovations such as Landreman's new method will enable reducing the time and cost investments required to construct new stellarators for research and ultimately for practical, energy-generating applications.

"This field is still in the basic research stage, and every new design is totally unique," Landreman said. "With these incompatible features to balance, there will always be different points where you can decide to strike a compromise. The REGCOIL method allows engineers to examine and model many different points along this spectrum."