Apr 6 2017

Scientists have come up with an innovative idea for using seaweed to develop a more sustainable processes for powering various devices. It is a known fact that seaweed is an edible algae that has been used in Asian cuisines for a long time and is now making its way into the Western food culture. At present, a research team has developed a material derived from seaweed that can enhance the performance of lithium-ion batteries, superconductors, as well as fuel cells.

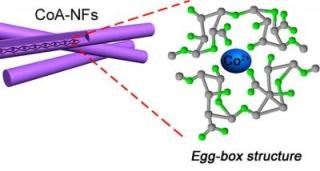

Scientists have created porous "egg-box" structured nanofibers using seaweed extract. Credit: American Chemical Society.

Scientists have created porous "egg-box" structured nanofibers using seaweed extract. Credit: American Chemical Society.

The outcomes of the research was presented by the researchers on April 5 at the 253rd National Meeting & Exposition of the American Chemical Society (ACS), until Thursday by ACS, the world’s largest scientific society. The meeting features over 14,000 presentations on a wide variety of scientific subjects.

According to Yang, the study proves to be an innovative idea for using materials abundant on earth to create future multifunctional, high-performance carbon nanomaterials for large-scale catalysis and energy storage.

Carbon-based materials are the most versatile materials used in the field of energy storage and conversion. We wanted to produce carbon-based materials via a really ‘green’ pathway. Given the renewability of seaweed, we chose seaweed extract as a precursor and template to synthesize hierarchical porous carbon materials.

Dongjiang Yang, PhD

According to Yang, the study proves to be an innovative idea for using materials abundant on earth to create future multifunctional, high-performance carbon nanomaterials for large-scale catalysis and energy storage.

Conventional carbon materials like graphite have proven to be indispensable for developing the prevalent energy landscape. However, development of futuristic lithium-ion batteries and storage devices mandates a superior material—a material which can be sustainably sourced—stated Yang.

With these factors in mind, Yang, who is working at Qingdao University, China, decided to to concentrate on the ocean. Being an abundant algae, seaweed can easily propagate in salty water. When Yang was working at Griffith University in Australia, he collaborated with researchers from the Qingdao University and from the Los Alamos National Laboratory in the United States to develop porous carbon nanofibers using seaweed extract. When metal ions like cobalt were chelated (i.e. bound) with the alginate molecules, resulted in nanofibers with an “egg-box” structure were formed. The alginate units nanofibers enveloped the metal ions. According to Yang, the “egg-box” structure is highly significant for the stability of the material and for controllable synthesis.

Investigations revealed that the reversible capacity of the material derived from seaweed was large, that is, 625 milliampere hours per gram (mAhg-1). This reversible capacity is much higher when compared to that of the conventional graphite anodes for lithium-ion batteries, which is 372 mAhg-1. Such a reversible capacity can aid in doubling the electric car range, provided the cathode material has similar quality. In addition to having a performance that was comparable to that of commercial platinum-based catalysts used in fuel-cell technologies, the egg-box fibers also have higher long-term stability. As a superconductor material, the egg-box fibers had a higher capacitance of 197 Farads per gram, thereby finding applications in zinc-air batteries and supercapacitors. From the time the researchers reported the initial outcomes of their study in 2015 in ACS Central Science, they have made further developments of the materials.

For instance, the researchers have used the same egg-box structure as a basis to eliminate defects in seaweed-based, lithium-ion battery cathodes that might hinder lithium ion movement, thereby affecting the performance of the battery. In the past, the researchers have created an innovative technique of using red algae-derived carrageenan and iron to produce a porous carbon aerogel doped with sulfur that has an ultra-high surface area. The innovative structure can prove to be a better choice for application in supercapacitors and lithium-sulfur batteries.

Nonetheless, commercialization of the seaweed-derived materials mandates further research. According to Yang, at present over 20,000 tons of industrial-use alginate precursor can be derived per year from seaweed. Yet, even greater amounts are required for ramping up the synthesis.