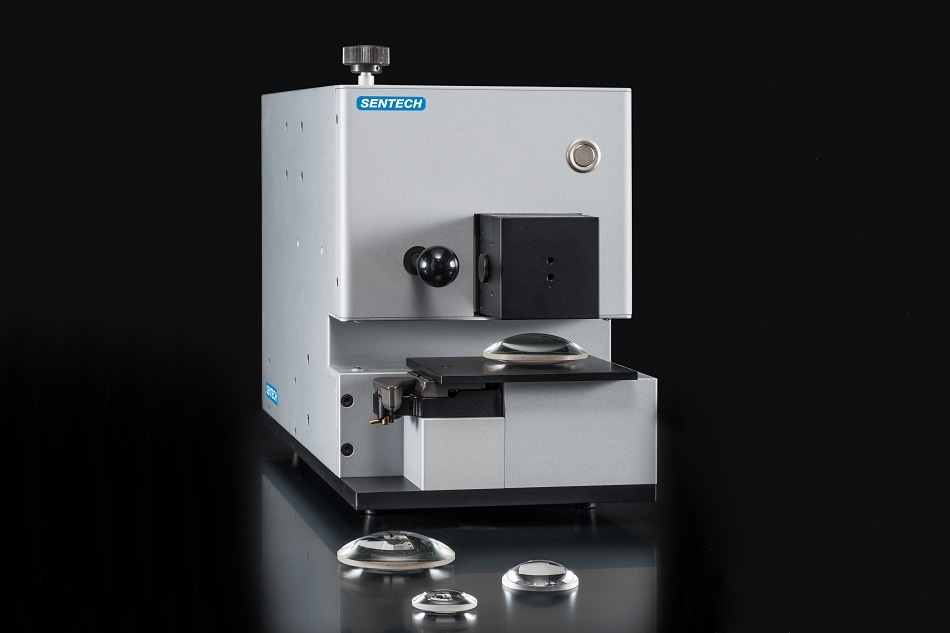

Image Credits: SENTECH

SENTECH is a project partner of the project "Research on highly flexible optical precision layers on polymer surfaces (FlexCoPlas)", which is supported by the funding initiative "Innovative Applications of Plasma Technology" of the German Federal Ministry of Education and Research. Within the three-year project period, an innovative measurement method and measuring device was developed using the technical know-how of SENTECH. Precise control of transmission properties of layer stacks on bowed plastic foils were realized as in situ monitoring and production control.

SENTECH achieved results within the project work in two areas:

First, an optical broadband monitoring with adaptive strategy based on the in situ transmission measurements was developed. This is based on adaptive strategies during deposition to determine current thicknesses and to calculate and signal the end point of current sublayers. Furthermore, layer changes of the already deposited stack (compacting, change in refractive index) are taken into account. The matching with quartz crystal microbalance data is used when available in order to improve design correction for target spectra. More than 10 layers can be evaluated and measured. Above all, the refractive index drift of the deposited material which is relevant for larger overall layer thicknesses is better compensated during depositions. Applications can be found for example in fields of high-quality filter layers, which depend on exact edge positions and transmission values.

Second, SENTECH was able to develop a device, which carries out transmission measurements on foils and lenses. It measures film parameters on bowed, waved, tensioned and/or microstructured films. The SENTECH measurement heads suppress these effects for robust measurements in the wavelength range 380 nm-2000 nm. The new measurement heads are designed for desktop applications as well as for in line / in situ measurement of e.g. roll-to-roll applications. A further application of the high acceptance range of sample alignment is the measurement of the transmission of lenses. The curvature influence is compensated by the optical setup. Thus, e.g. antireflective coatings on lenses can be easily controlled.

The FlexCoPlas project was funded for three years and was finished in 2017. It studied possible use cases of the so-called "4th Element" plasma and its applications as a key element in many industries. The aim is to gain significant improvements and innovations of plasma deposited layer stacks by means of systematic research. A group of 9 companies and research facilities was involved in the project. The BMBF funded this project with a total of EUR 2.64 million within Photonics Research Germany's funding initiative "Innovative Applications of Plasma Technology".