-2.jpg) By Thomas HornigoldMar 14 2018

By Thomas HornigoldMar 14 2018The physics of materials that can be made atomically thick is fascinating, rich, and varied. As well as providing a playground for condensed-matter theorists and experimentalists, materials scientists are exploring a broad range of applications for 2D materials, thin films, and nanolayers. Most famous, of course, are the graphene and carbon nanotubes, which operate on the incredibly chemically flexible properties of carbon. But carbon is far from the only element or compound that can be manipulated in this way.

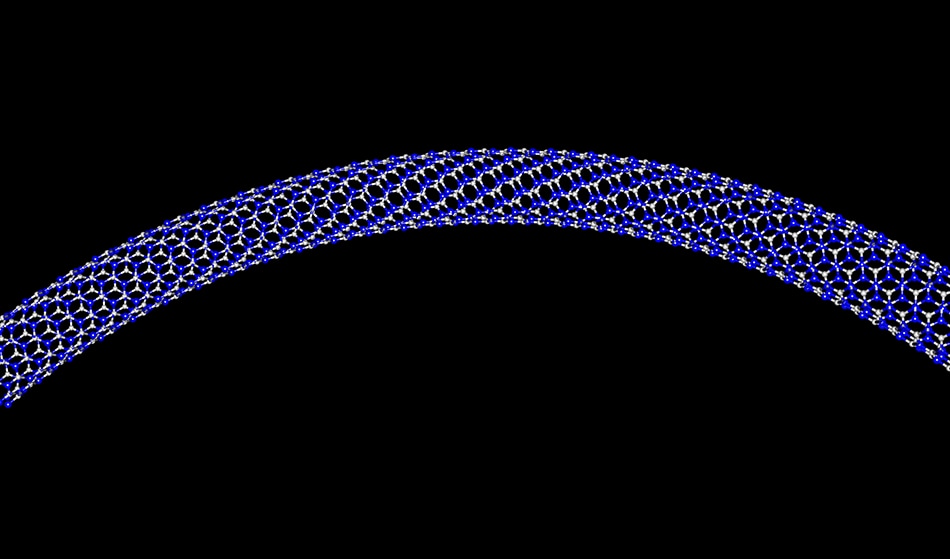

The Boron Nitride compound was traditionally manufactured due to its high-temperature resilience and chemical stability. It was, therefore, used as a high-temperature ceramic. However, its chemical structure allows for nanotubes of boron nitride to be produced that are similar to carbon nanotubes. Predicted in 1994 and synthesized the next year, these nanotubes have very different properties; unlike carbon nanotubes, they are electrical insulators, and they’re also more thermal and chemically stable than their carbon cousins. This enhanced thermal stability – as well as their increased resistance to neutron radiation – has meant that suggested applications include extreme environments like outer space.

Image Credit: Igor Petrushenko/Shutterstock

Image Credit: Igor Petrushenko/Shutterstock

Back in 2015, a group of scientists from the mechanical engineering department at the State University of New York at Binghamton demonstrated that boron nitride nanotubes could provide even more strength per unit weight than their carbon cousins. The results were published in Applied Physics Letters. By themselves, the strength of the nanotubes is similar to carbon nanotubes – but when they are interfaced with a polymer, the fact that the boron nitride nanotubes adhere strongly to the polymer gives them the edge over carbon.

"The weakest link in these nanocomposites is the interface between the polymer and the nanotubes," said associate professor Changhong Ke.

By examining the way that these composites could be ripped apart – and seeing how the structure responded under torsion – the scientists were able to determine that the adhesion level depended on the polymer used.

The theoretical underpinning for this advanced strength is because boron nitride is a compound of two elements; the charge distribution is therefore uneven, as the nitrogen atom has more protons than the boron atom and shifts the electronic charge distribution towards its position. This causes a stronger charge interaction between the nanotube and the polymer.

A further advantage of boron nitride nanotubes is that they are piezoelectric; under pressure, they can produce electrical charges. In 2017, a further – and potentially very important – application for boron nitride was discovered. Scientists at Rice University were able to construct a boron nitride foam, composed of 2-D sheets of hexagonal boron nitride, which could absorb carbon dioxide.

Given that many of the projections for satisfying the Paris Agreement require negative carbon dioxide emissions, scientists have been thinking hard about ways of sucking carbon dioxide out of the atmosphere. The classic solution was to use biofuels, and capture the CO2 that’s released when these are burned – but under some projections, the biofuels required would simply take up too much land on Earth. For this reason, those proponents of “direct air capture” are on the prowl for a material that can absorb carbon dioxide from the air – and preferably can be scrubbed clean without expending too much energy.

The boron nitride foam seems like it could be an interesting candidate; in molecular dynamics simulations, it could absorb 340% of its weight in carbon dioxide. It’s porous and tuneable, which means it can be adapted to filter many different kinds of gas. The foam was created by freeze-drying the 2D layers of boron nitride and then adding polyvinyl alcohol (PVA).

Even a very small amount of PVA works. It helps make the foam stiff by gluing the interconnects between the h-BN sheets - and at the same time, it hardly changes the surface area at all.

Chandra Sekhar Tiwary, Co-Author & Rice Postdoctoral Researcher

The idea here would then be to evaporate the CO2 out of the boron nitride foam once used so that the material can be reused to absorb more carbon dioxide. Different coatings seem to have different effects for the foam – when coated with the polymer PDMS, the foam became an effective shield from lasers that could find use in biomedical or industrial applications. The ultimate aim of the Rice team’s future research would be enhanced control over the pore size of the foam, which could turn it into a useful filter for tasks like separating oil and water.

As yet, the main disadvantage of boron nitride is the cost – those nanotubes can cost $1000/gram, rather than $10-20/gram for their carbon cousins. However, as this material is fairly new, the price is likely to drop as more useful applications are found, and they start to become mass-produced; carbon nanotubes have fallen down a similar price curve. Due to the enhanced thermal stability and adhesion to polymers, they may well become the favored nanotube material for use in certain industries like air and space – and the carbon-dioxide filtration potential is sure to be investigated further.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.