Precision sensor manufacturer Micro-Epsilon has extended its range of confocal chromatic displacement sensors with a new compact sensor that offers outstanding value for money and high accuracy, enabling its cost effective use in high volume OEM, machine building, systems integration and continuous production applications.

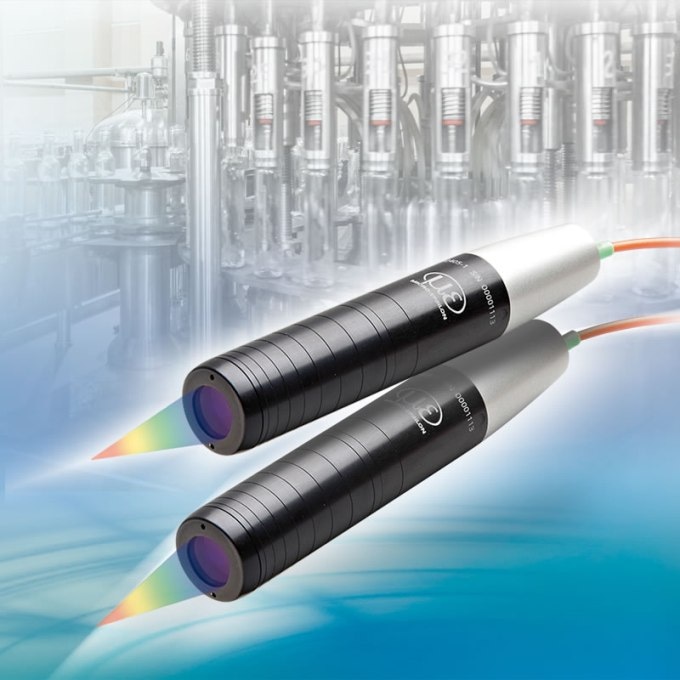

The confocalDT IFS2406-3 confocal chromatic displacement sensor is designed for high precision distance, position and thickness measurements. The performance of the sensor is almost as high as the market leading confocal IFS2405 series, yet has a much more compact footprint. With a diameter of 19mm, the confocalDT IFS2406-3 is easily integrated in restricted, confined spaces. Due to an offset distance of 74mm and a measuring range of 3mm, the sensor is particularly useful when increased process reliability and protection of the sensor and target from mechanical damage are required. Special lens technology allows the sensor to deliver a high resolution with an extremely small laser spot size (35µm diameter).

With a compact footprint and small measuring spot size, the confocal IFS2406-3 is ideal for high accuracy distance measurements on reflecting or transparent surfaces, as well as one-sided thickness measurement of transparent film, plates or layers. As well as distance measurements on highly reflective, shiny surfaces, the sensors can also be used to measure on dark, diffuse materials. Typical applications include displays, smartphones, mirrors and glass production and medical devices. The sensors are also suitable for vacuum applications in semiconductor and microelectronics production.

The confocalDT IFS 2406-3 has a resolution of 50nm and a linearity of +/- 1.5µm (for distance and displacement measurements) and +/- 3µm (for thickness measurements). Operating temperature range is from +5°C to +70°C and is protected to IP65.

Together with the confocal chromatic controller, confocalDT 242x, the sensor system offers an excellent price-performance ratio, particularly for OEM series production applications. The confocalDT IFS 2406-3 sensor is compatible with all confocal controllers from the Micro-Epsilon range.

With the confocalDT 2421 and 2422 confocal controllers, Micro-Epsilon is setting new performance standards in precision confocal measurement technology. Designed as a single or dual-channel version, these confocal chromatic measurement systems enable a cost effective solution for OEMs. The system works on a non-contact basis and is therefore wear-free. The active exposure control of the CCD line allows fast, accurate compensation when measuring on different surfaces.

Measurement data can be output in real time via the EtherCAT interface. Thickness calibration allows accurate thickness measurement over the entire measuring range of the sensor.

For more information on the confocalDT IFS 2406-3, please call the Micro-Epsilon sales department on 0151 355 6070 or email [email protected]