Feb 27 2019

Characterizing electrically heated silicate glass and predicting its behavior is essential as it is used in a range of devices that steer technical innovations.

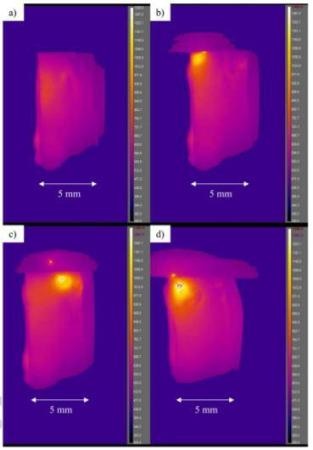

Another surprising observation of electric heating of glass is that the hot spot near the positive electrode may meander around as seen in the video frames several seconds apart in the figure here. (Image credit: Himanshu Jain, Nicholas J. Smith, Craig Kopatz, and Charles T. McLaren)

Another surprising observation of electric heating of glass is that the hot spot near the positive electrode may meander around as seen in the video frames several seconds apart in the figure here. (Image credit: Himanshu Jain, Nicholas J. Smith, Craig Kopatz, and Charles T. McLaren)

Silicate glass is used in display screens and glass fibers power the Internet. Nanoscale glass devices are being employed to offer revolutionary medical treatments, for example, re-growing tissue and targeted drug delivery.

The finding that the electrically heated silicate glass, under specific conditions, disobeys a long-established law of physics called Joule’s first law should be of interest to a wide array of engineers, researchers, and even the general public, stated Himanshu Jain, Diamond Distinguished Chair of the Department of Materials Science and Engineering at Lehigh University.

As early as 1840, James Prescott Joule, an English physicist and mathematician, provided the basis for electrical heating. Joule established that when electrical current is passed through a resistor, heat is produced. His inference, called Joule’s first law, simply claims that the heat generated is proportional to the square of the electrical current that passes through a material.

It has been verified over and over on homogeneous metals and semiconductors which heat up uniformly, like an incandescent light bulb does.

Himanshu Jain, Diamond Distinguished Chair, Department of Materials Science and Engineering, Lehigh University.

He and his teammates—including Nicholas J. Smith and Craig Kopatz, both of Corning Incorporated, as well as Charles T. McLaren, a former PhD student of Jain, now a researcher at Corning—have authored a paper reported in Scientific Reports on February 26th, 2019, which explains their findings that electrically heated common, homogeneous silicate glasses seem to disobey Joule’s first law.

In the paper, titled “Development of highly inhomogeneous temperature profile within electrically heated alkali silicate glasses,” the authors write: “Unlike electronically conducting metals and semiconductors, with time the heating of ionically conducting glass becomes extremely inhomogeneous with the formation of a nanoscale alkali-depletion region, such that the glass melts near the anode, even evaporates, while remaining solid elsewhere. In situ infrared imaging shows and finite element analysis confirms localized temperatures more than a thousand degrees above the remaining sample depending on whether the field is DC or AC.”

“In our experiments, the glass became more than a thousand degrees Celsius hotter near the positive side than in the rest of the glass, which was very surprising considering that the glass was totally homogeneous, to begin with,” states Jain. “The cause of this result is shown to be in the change in the structure and chemistry of glass on nanoscale by the electric field itself, which then heats up this nano-region much more strongly.”

According to Jain, the application of standard Joule’s law of physics has to be reassessed carefully and adapted to comply with these discoveries.

These observations explain the source of a recently discovered electric field-induced softening of glass. In a previous paper, Jain and his team described the phenomenon of Electric Field Induced Softening. They showed that the softening temperature of glass heated in a furnace can be decreased by approximately a couple of 100 ○C by just applying 100 V across a sample that is one inch thick.

The calculations did not add up to explain what we were seeing as simply standard Joule heating. Even under very moderate conditions, we observed fumes of glass that would require thousands of degrees higher temperature than Joule’s law could predict!

Himanshu Jain, Diamond Distinguished Chair, Department of Materials Science and Engineering, Lehigh University.

The team then carried out a systematic study to track the temperature of glass. They mapped out the temperature profile of the entire sample using high-resolution infrared pyrometers. Their previous observations, as well as the new data, proved that electric field radically altered the glass and that they needed to revise how Joule’s law can be applied.

The scientists think that this research demonstrates that heat in a glass can be produced on a much finer scale when compared to the methods used to date, probably down to the nanoscale. It would then enable new optical and other complex structures and devices on the glass surface to be made more accurately than before.

“Besides demonstrating the need to qualify Joule’s law, the results are critical to developing new technology for the fabrication and manufacturing of glass and ceramic materials,” states Jain.