Jul 22 2019

Lithium metal anode has the potential to upgrade the energy density of lithium-ion batteries for its low voltage (−3.04 V vs Li/Li+) and high specific capacity (3800 mAh g−1).

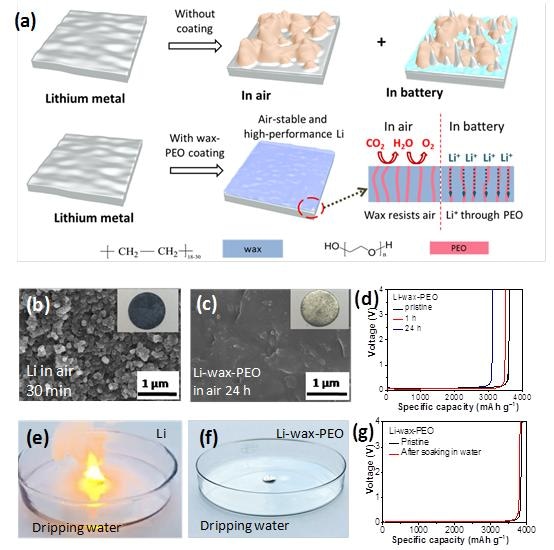

The diagram of the Li-wax-PEO and its stability in the air and water. (Image credit: Science China Press)

The diagram of the Li-wax-PEO and its stability in the air and water. (Image credit: Science China Press)

However, the safety problems due to the dendrite growth and the instability in air caused by its high chemical activity restrict its large-scale use as an electrode material. Lithium metal is highly sensitive to moisture and oxidative components in the air, resulting in the formation of insulating products such as lithium hydroxides on its surface and the resultant worsening of the electrochemical performance.

Furthermore, when lithium is exposed to water, combustion and explosion might occur because of the generation of heat and hydrogen. Lithium metal’s sensitivity increases the pressing needs during the shipping, storage, and processing of the lithium metal anode. It is thus very much preferred to create an air-stable, waterproof lithium metal anode for its practical application in the future.

In the electronics domain, the packaging technology safeguards electronic components from the corrosion in humid air and water and from the physical damage by a coating that offers a design concept for lithium metal protection.

A group of scientists headed by Prof. Quan-Hong Yang from Tianjin University and Prof. Wei Lv from Tsinghua University recently created a wax-PEO coating on the surface of lithium metal by a simple dip-coating technique to achieve an air-stable, waterproof lithium metal anode. Since wax is an inert sealing material that is commonly used, it can be easily coated on the lithium metal surface.

The resultant wax-based composite coating avoids the undesirable reactions of lithium metal in the water and air. In the case of batteries, the coating hinders the etching of electrolyte to the surface of lithium metal anodes while the homogeneously distributed PEO ensures the uniform lithium-ion conduction at the interface and stops the growth of lithium dendrites.

With protection from the wax-PEO coating, lithium surface remains unaltered in the air with a high relative humidity of 70% for 24 hours, realizing the high capacity retention of 85%. Even upon direct contact with water, lithium does not undergo capacity decay or combustion.

The coated lithium metal anode remains stable for a maximum period of 500 hours in symmetric cells, and the lithium-sulfur batteries assembled with the coated lithium metal anode exhibit a low capacity decay rate of 0.075% per cycle for 300 cycles. This study shows an efficient package technology for the air-stable, waterproof lithium metal anodes, which can be easily scaled and applied to other sensitive electrode materials.

This research is supported by the National Science Fund for Distinguished Young Scholars, China (51525204), National Natural Science Foundation of China (51772164 and U1601206), Guangdong Natural Science Funds for Distinguished Young Scholar (2017B030306006), Guangdong Special Support Program (2017TQ04C664), Local Innovative and Research Teams Project of Guangdong Pearl River Talents Program (2017BT01N111), and the Shenzhen Basic Research Project (JCYJ20170412171630020 and JCYJ20170412171359175).