Anisoprint and Polymaker have started collaboration to bring the opportunity of printing composite parts with a certain chemical and mechanical properties offering manufacturing solutions to industrial users.

One of the features of Anisoprint continuous fiber 3D printing is the possibility to choose any plastic with a processing temperature up to 270°С as a matrix material. Polymaker supplies a wide range of engineering 3D printing materials (PETG, ABS, PC, PLA, PAs, etc) so the collaboration of the companies combines a variety of mechanical properties with the manufacturing of composite parts.

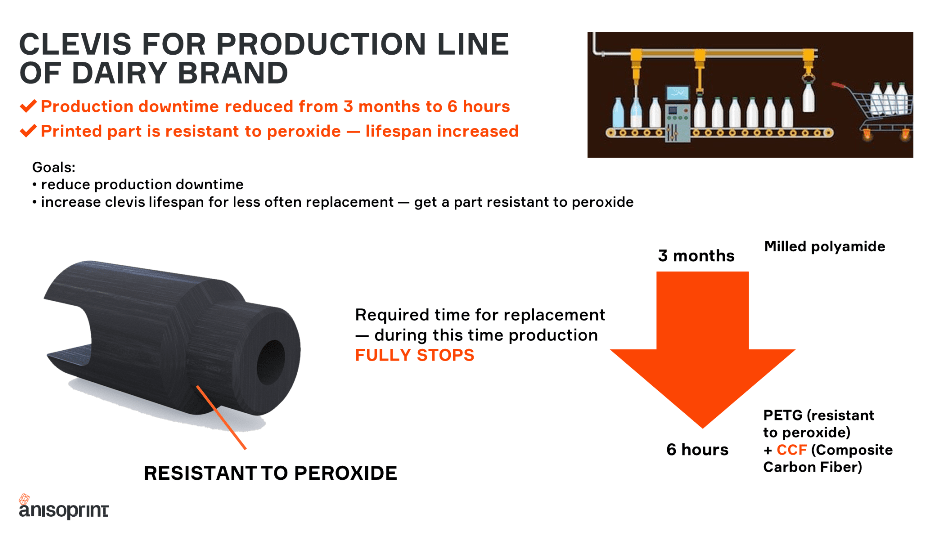

Let’s have a look at a recent application case from a dairy brand production line.

Clevis moves through the production line, catches a yoghurt bottle and sends it to the washing area. The part is washed with hydrogen peroxide which is corrosive to certain materials. PETG plastic is resistant to hydrogen peroxide which makes it a good material choice for the part.

The clevis was printed on Anisoprint Composer 3D printer using PETG reinforced with Composite Carbon Fiber. This adds toughness and rigidity, boosting the lifespan of the clevis. Production time was significantly reduced in comparison to the original part from milled polyamide but the main feature is its resistance to peroxide.

With Anisoprint CFC (Composite Fiber Co-extrusion) technology plastic is reinforced with continuous composite fibers directly during the printing process. It allows using any plastic you want to make a strong, light and relatively cheap part with the required properties.

Polymaker produces a wide range of plastics, each with unique properties covering: heat, chemical, weather and impact resistance. Polymaker designs these materials specifically for 3D printing so they are easy to work with and print with reliable results. Combined with Anisoprint’s CFC technology, users can achieve a composite part which is lightweight with high strength and tailored to specific industrial applications.

Thus you can print a composite that has exactly the properties you need for your certain goal.

Anisoprinted composite parts are stronger, lighter and cheaper than their counterparts from other materials (metal, plastic, non-optimized composites). With all the variety of physical properties polymers can have, this combination can provide manufacturing solutions for companies in many fields which cannot be achieved with other printing technologies.

Polymaker is a company that produces advanced 3D printing materials specifically engineered for a wide range of industries. With an ever-growing portfolio of materials, Polymaker offer industry solutions to high heat applications, flame retardance, investment casting and support materials. At the heart of Polymaker is a large research and development laboratory which drives the company forward through constant innovation and testing. All Polymaker materials are formulated for 3D printing while maintaining the unique properties inherent to the respective material.

Anisoprint is a manufacturer of 3D printers, materials and software for producing composites with continuous fibers of a new era. The company was founded by researchers and engineers to bring a new optimal way of manufacturing and make composites possible to apply in the fields they never be before, decreasing manufacturing costs and discovering new properties of materials.