SABIC has announced that it is spotlighting its diverse and expanding collaborations that deliver value to customers by providing the company’s specialized materials at various points throughout the global additive manufacturing value chain at FORMNEXT 2019 (Hall 12.1, B61).

Collaborations to Foster Innovations

The company’s goals for these collaborations are to foster innovation and steadily expand application development opportunities for additively produced parts. To that end, SABIC is well positioned to supply a variety of unique material chemistries that can address critical customer and value chain partner challenges in additive manufacturing.

“As the additive manufacturing industry grows and diversifies, there is increasing demand for specialized materials that can be delivered when, where and how they are needed throughout the value chain,” said Keith Cox, senior business manager, Additive Manufacturing, SABIC. “Whether it’s filament manufacturers that need access to high-performance resins, equipment manufacturers that need resins or filaments tuned to their printers, service bureaus that require printable materials for use in commercial printers, or OEMs whose large format additive manufacturing applications call for specialty compounds, SABIC is actively engaged with additive manufacturing innovators and the industry as a whole.”

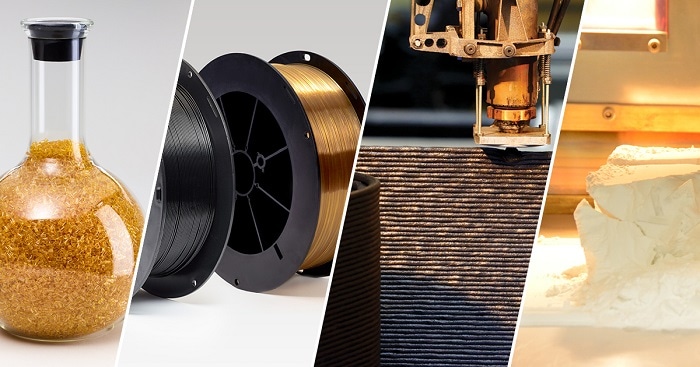

Specialized Resins for Printable Materials

For providers of printable materials designed to work in proprietary equipment or for general use, SABIC offers specialized resins formulated for extrusion into filaments or the production of powders for selective laser sintering (SLS). For example, SABIC supplies ULTEM™ 9085 resin, a polyetherimide (PEI) blend, to Stratasys to produce filaments for its Fortus® line of printers.

Filaments for Equipment Manufacturers

Other equipment manufacturers collaborate with SABIC to develop high-performance printable material solutions aligned with their printer capabilities, in order to expand solutions for their customers. As recently announced, SABIC is providing ultra-high-temperature EXTEM™ AMHH811F filament to Italy’s ROBOZE for its ARGO production 3D printers.

The 247°C glass transition (Tg) temperature of EXTEM™ AMHH811F filament helps to expand opportunities for high-heat applications in a variety of industries. The two companies worked together to optimize printing parameters and secure UL Blue Card recognition with UL94-V0 certification at 0.75mm on samples printed with ROBOZE ARGO Production 3D printers. At the SABIC booth, several parts printed with EXTEM™ AMHH811F filament will be on display.

“Collaborating with companies such as ROBOZE to provide specialized material technologies that address the need for higher-performing solutions expands opportunities for customer application innovation,” Cox continued. “We hope to participate in more engagements like this throughout the value chain to accelerate additive manufacturing growth.”

High-quality Materials for Part Manufacturers

Part manufacturers, including service bureaus, collaborate with SABIC to gain access to high-quality printable materials and related processing expertise and resources. SABIC’s filaments are developed to meet stringent specifications that help ensure consistent processing, repeatability and optimized part performance. To benefit large-format additive manufacturers, SABIC compounds provide reduced lot-to-lot and within-lot variability, which helps improve processing consistency that is critical for multi-hour printing projects.

For instance, SABIC supplies LNP™ THERMOCOMP™ AM compounds to Additive Engineering Solutions (AES), a U.S.-based large format service bureau. SABIC’s expertise in large format additive manufacturing materials and processing have been developed over several years of hands-on work with its in-house Cincinnati Incorporated Big Area Additive Manufacturing® machine, located at the Pittsfield Polymer Processing Development Center in Massachusetts, USA.

This knowledge is helping AES save time and resources by optimizing printing and expediting troubleshooting. AES’s printed parts on display at the SABIC stand include a high-heat autoclavable tool for composites made with an ULTEM™-based compound and a scaled-down version of a large precast concrete mold made with a reinforced acrylonitrile-butadiene-styrene (ABS)-based compound. Gate Precast used 3D printed precast concrete molds in the redevelopment of the Domino Sugar Refinery property in Brooklyn, N.Y.

Materials Expertise for Specifiers/OEMs

To support the application development activities of specifiers and OEMs, SABIC offers unique chemistries, materials expertise, processing knowledge and a deep understanding of requirements for vertical industries such as healthcare, automotive and aerospace. In its ongoing collaboration with Local Motors, headquartered in Phoenix, Ariz., SABIC is supplying materials from its LNP™ THERMOCOMP™ AM portfolio of reinforced compounds, which are used in production of the Olli, the world’s first co-created, self-driving electric vehicle. This is the latest project for the two companies, whose history spans many years and includes development of the world’s first 3D-printed car.

Collaboration for Autoclave Composite Tooling Applications

In collaboration with the National Institute for Aviation Research (NIAR) at Wichita State University (WSU), SABIC is helping to develop high-temperature printable materials for use in autoclave composite tooling applications for the aerospace industry.

“SABIC’s expertise has been an invaluable part of WSU NIAR’s Research and Development efforts in manufacturing quick turnaround, low-cost tooling for aerospace applications using large scale additive manufacturing methods on the Cincinnati Incorporated Big Area Additive Manufacturing machine,” said Jeswin J. Chankaramangalam, program manager, Emerging Technologies, NIAR.

“This collaboration demonstrates the use of large-format additive manufacturing to print one of the most demanding applications in the aerospace industry, with the potential to offer substantial savings through the reduction of production costs, lead time and inventory.”

SABIC’s technical, sales and marketing experts are available throughout FORMNEXT 2019 to discuss the company’s portfolio of additive manufacturing solutions and the collaborations delivering material technologies across the value chain.