CAMBRIDGE, MA: Lambient Technologies LLC, the leader in precision measurement solutions for the curing of advanced polymer materials, will now provide cure testing services. These services extend the benefits of dielectric cure monitoring to organizations that may only have an occasional need to gather data about material cure.

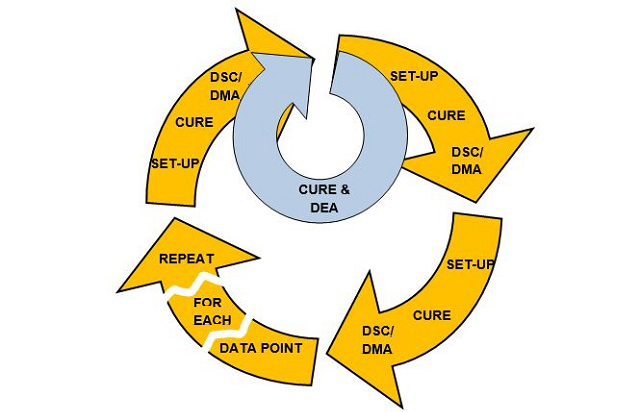

Dielectric Analysis (DEA) enables rapid feedback in the process development cycle.

With Lambient Technologies’ cure testing services, companies working with thermoset resins or advanced composites such as carbon fiber prepreg will gain the critical data necessary to improve manufacturing throughput. With this data, they can identify flaws or inconsistencies in raw materials obtained from outside suppliers. Curing behavior can vary from batch to batch or even within an individual roll of a material such as carbon fiber prepreg. With data provided by Lambient Technologies, companies can work with suppliers to improve the consistency of raw materials.

Organizations that use resins and prepregs may want to test incoming materials periodically to ensure they are receiving materials that cure to specifications. In addition, manufacturers of resins and prepregs may wish to test outgoing materials periodically to ensure they are sending consistent product to their customers. Our testing services will provide researchers with information about the curing of their materials, illustrating the effect of formulation and different time-temperature schedules on cure and cure time.

Customers can submit material samples before engaging our testing services. If we determine that the material is one that can’t be measured with our equipment, there will be no charge. In addition, if customers engage our testing services and decide at a later point to purchase one of our DEA instruments, a portion of their testing expenditure will be applied to the cost of an instrument.

Lambient Technologies designs and produces instruments for real-time analysis of the curing of thermosets and advanced composite materials such as those used in aerospace, automotive, and wind power applications. Our products offer unique insights into how these materials react and change during curing, processing, and manufacturing. Armed with this critical data, users can proceed with research, quality testing, and final production, confident in the integrity of their processes and materials—and in the reliability of their finished products. For more information, visit https://lambient.com/ or email [email protected].