AnalySwift, LLC, a provider of efficient high-fidelity modeling software for composites and other advanced materials, announced today its sponsorship of both the SAMPE 2020 Student Bridge Contest and Student Additive Manufacturing Contest.

“We thank AnalySwift for their support in providing the design and analysis tools for our students in these competitions. With AnalySwift’s support, students can use the composite simulation software to validate and optimize their unique designs,” SAMPE Vice President, Scott Stephenson said.

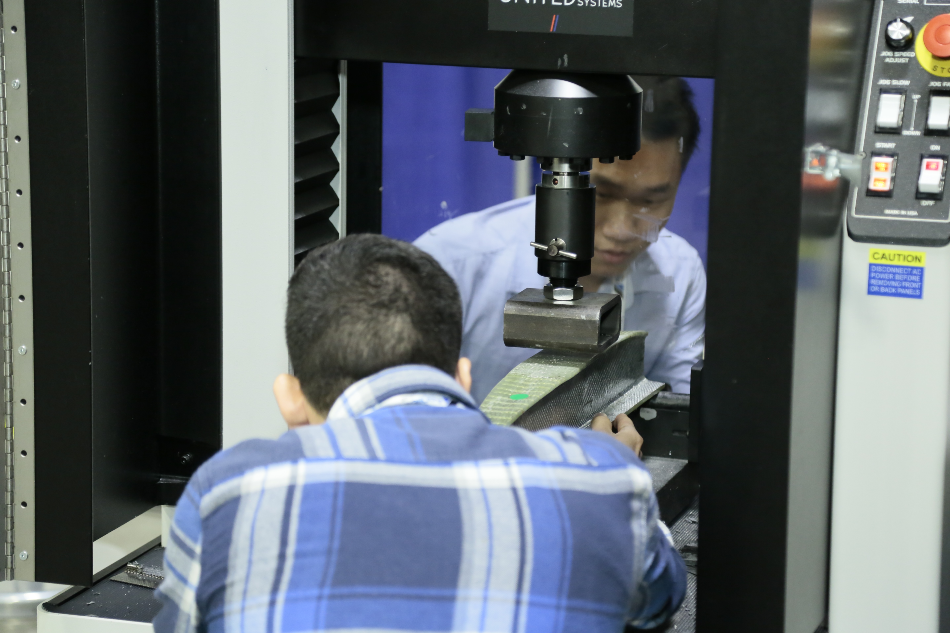

Hosted by SAMPE (Society for the Advancement of Material and Process Engineering), the Student Bridge Contest engages students through a team competition designing, manufacturing, and testing small-scale structural bridges made from composite materials. Winners in the Bridge Contest receive notoriety, including cash and the SAMPE Student Bridge Champion trophy.

Also hosted by SAMPE, the Student Additive Manufacturing Contest provides an opportunity for students to learn and expand their abilities in additive manufacturing and engineering design. Students in the Additive Manufacturing Contest compete for a 3D printer and cash prizes.

“With participation worldwide, these contests are an excellent opportunity for students interested in pursuing a career in advanced composites,” said Allan Wood, president & CEO of AnalySwift. “AnalySwift is pleased to offer student teams free access to the VABS composite simulation software. VABS helps accelerate students’ design and analysis with its rigorous modeling of slender composite structures, such as bridges, columns, and other structures typically handled as beams. For instance, VABS quickly calculates accurate bending stiffness, neutral axis, extension stiffness, failure index, and strength ratios. Students can use VABS on a typical laptop computer to calculate the ply-level details with the accuracy of 3D FEA in seconds.”

This will be the 23rd year SAMPE has hosted the event, which will be held May 6, 2020, at the SAMPE 2020 convention in Seattle, Washington. According to SAMPE, 73 teams from 13 universities and colleges from 5 countries participated in the Bridge Contest in 2019, with 7 teams from 4 universities and colleges participating in the Additive Manufacturing Contest. For more information on the Bridge Contest, including how student teams can access VABS, please visit the SAMPE Student Bridge Contest webpage. For more information on the Additive Manufacturing Contest, please visit the SAMPE Student Additive Manufacturing Contest webpage.

“VABS is capable of rigorously reducing an original 3D slender solid with complex cross-sections into a simple engineering beam model,” according to Dr. Wenbin Yu, CTO of AnalySwift. “With continuous development funded by the US Army and other agencies spanning over 30 years for performance and robustness, VABS’ accuracy has been extensively verified. ”

VABS is a general-purpose cross-sectional analysis tool for computing beam properties and recovering 3D stresses/strains of slender composite structures. It is a powerful tool for modeling composite helicopter and wind turbine rotor blades, as well as other slender composite structures, such as landing gear, propellers, high-aspect ratio wings, golf club shafts, fishing rods, columns, poles, shafts, and rods. Please visit the VABS webpage to learn more.