Feb 10 2021

Researchers at Uppsala University, in collaboration with Swedish graphene materials company Graphmatech, have demonstrated a potential breakthrough in the printability of copper for laser additive manufacturing (AM), significantly lowering the reflectivity of copper powder to achieve more dense printed parts.

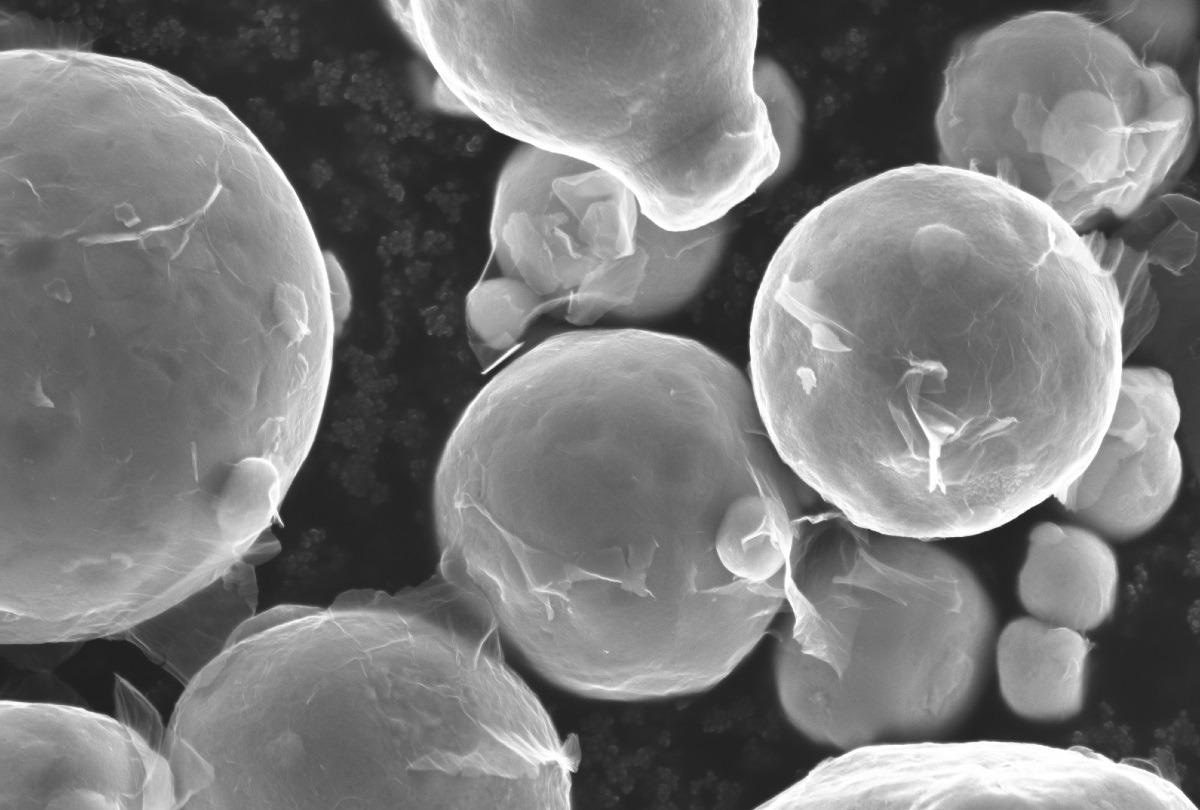

Copper powder was coated using Graphmatech’s patented graphene technology. Image Credit: Simon Tidén / Uppsala University

Copper powder was coated using Graphmatech’s patented graphene technology. Image Credit: Simon Tidén / Uppsala University

Additive manufacturing of metals has seen rapid uptake across a range of industries due to its ability to produce customized and complex designs on demand, as well as offering more sustainable manufacturing with reduced waste and lower material requirements.

However, some metals, including pure copper, have proven a challenge due to their high reflectivity. At the wavelengths commonly used in laser powder bed fusion (the dominant technology in metal AM), only a small part of the energy is absorbed by the material, resulting in low density printed parts

Graphene technology offers a solution

“By modifying the surface of the copper powder using Graphmatech’s patented graphene technology, we successfully reduced the reflectance by up to 67%”, explains Graphmatech CEO Dr Mamoun Taher. The graphene incorporated also survived the printing process to positively impact the density of the printed copper-graphene parts, significantly reducing their porosity.

The research is being undertaken by Professor Ulf Jansson's research group at Ångström Laboratory, Uppsala University, with PhD student Simon Tidén having recently been awarded a poster prize at the Swedish Arena for Additive Manufacturing of Metals Conference for the work.

“The new process developed to coat metal powder with graphene opens up very interesting perspectives for the design of new materials in various applications”, states Professor Jansson.

“This 3D printable hybrid material has the potential to add value in a range of sectors such as e-mobility, electronics and defence,” adds Dr Taher.

Graphmatech are now actively scaling up this technology, having already made significant advances in other graphene-metal composites and coated powders for additive manufacturing with project partners, due to the potential for graphene in enhancing the processability of powders and the properties of printed parts.