Jun 4 2021

In the near future, the number of data-transmitting microdevices, for example, in transport and packaging logistics, is expected to increase significantly. While all these devices require energy, the amount of batteries would have a crucial impact on the environment.

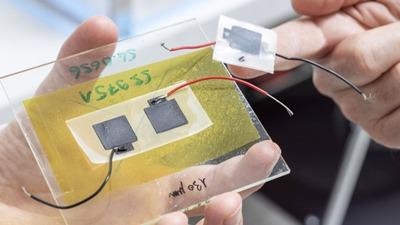

The biodegradable battery consists of four layers, all flowing out of a 3D printer one after the other. The whole thing is then folded up like a sandwich, with the electrolyte in the center. Image Credit; Gian Vaitl/Empa.

Empa scientists have now designed a biodegradable mini-capacitor that can overcome this concern. This capacitor contains glycerin, cellulose, carbon and table salt and operates reliably.

The fabrication device for the battery insurgency seems to be quite inconspicuous: It is a commercially available, modified 3D printer placed in a room in the Empa laboratory building. But the actual breakthrough lies in the recipe for gelatinous inks that can be dispensed onto a surface by this 3D printer.

The targeted mixture contains cellulose nanocrystallites and cellulose nanofibers, in addition to carbon in the form of activated carbon, graphite, and carbon black. To liquefy all this, scientists used water, glycerin and two different kinds of alcohol, and also a pinch of table salt for ionic conductivity.

A Sandwich of Four Layers

To fabricate a functioning supercapacitor from these ingredients, four layers are required, such as the electrode, a conductive layer, a flexible substrate, and finally the electrolyte, all flowing out of the 3D printer one after the other. The entire thing is subsequently folded up similar to a sandwich, keeping the electrolyte in the middle.

The result is an ecological wonder. The mini-capacitor from the laboratory can preserve electricity for several hours and can already drive a tiny digital clock. It can tolerate years of storage and thousands of charge and discharge cycles even in freezing temperatures and is impervious to both shocks and pressures.

Biodegradable Power Supply

And the best part is that the capacitor can be tossed in the compost or can be simply left in nature to degrade when it is no longer needed. After a couple of months, the capacitor should have decomposed, leaving just a few visible particles of carbon. The investigators have already attempted this method too.

“It sounds quite simple, but it wasn’t at all,” stated Xavier Aeby from Empa’s Cellulose & Wood Materials laboratory. It took an elaborate range of tests until all the parameters were correct, until all the parts flowed consistently from the printer, and the capacitor worked suitably.

As researchers, we don’t want to just fiddle about, we also want to understand what's happening inside our materials.

Xavier Aeby, Cellulose & Wood Materials, Empa

Along with his supervisor Gustav Nyström, Aeby designed and applied the idea of a biodegradable electricity storage device. He came to Empa for his doctorate, after studying microsystems engineering at EPFL.

Nyström and his research team have been studying nanocellulose-based functional gels for some time. The material is a renewable and eco-friendly raw one and its internal chemistry also makes it highly versatile.

The project of a biodegradable electricity storage system has been close to my heart for a long time. We applied for Empa internal funding with our project, Printed Paper Batteries, and were able to start our activities with this funding. Now we have achieved our first goal.

Gustav Nyström, Supervisor, Empa

Application in the Internet of Things

Nyström and Aeby believe that the supercapacitor may soon become a major component for the Internet of Things.

“In the future, such capacitors could be briefly charged using an electromagnetic field, for example, then they could provide power for a sensor or a microtransmitter for hours.”

For example, this could be used to check the contents of separate packages during transportation. Powering sensors in agriculture or environmental monitoring is also conceivable—there is no need to obtain these batteries again because they could simply be left in nature to degrade.

The number of electronic microdevices will also be rising because of a much more extensive use of near-patient laboratory diagnostics ('point of care testing'), which is presently thriving. Among these are self-testing devices for diabetics or miniature test devices for bedside use.

A disposable cellulose capacitor could also be well suited for these applications.

Gustav Nyström, Supervisor, Empa

The biodegradable battery

Video Credit: Empa.

Journal Reference:

Aeby, X., et al. (2021) Fully 3D Printed and Disposable Paper Supercapacitors. Advanced Materials. doi.org/10.1002/adma.202101328.