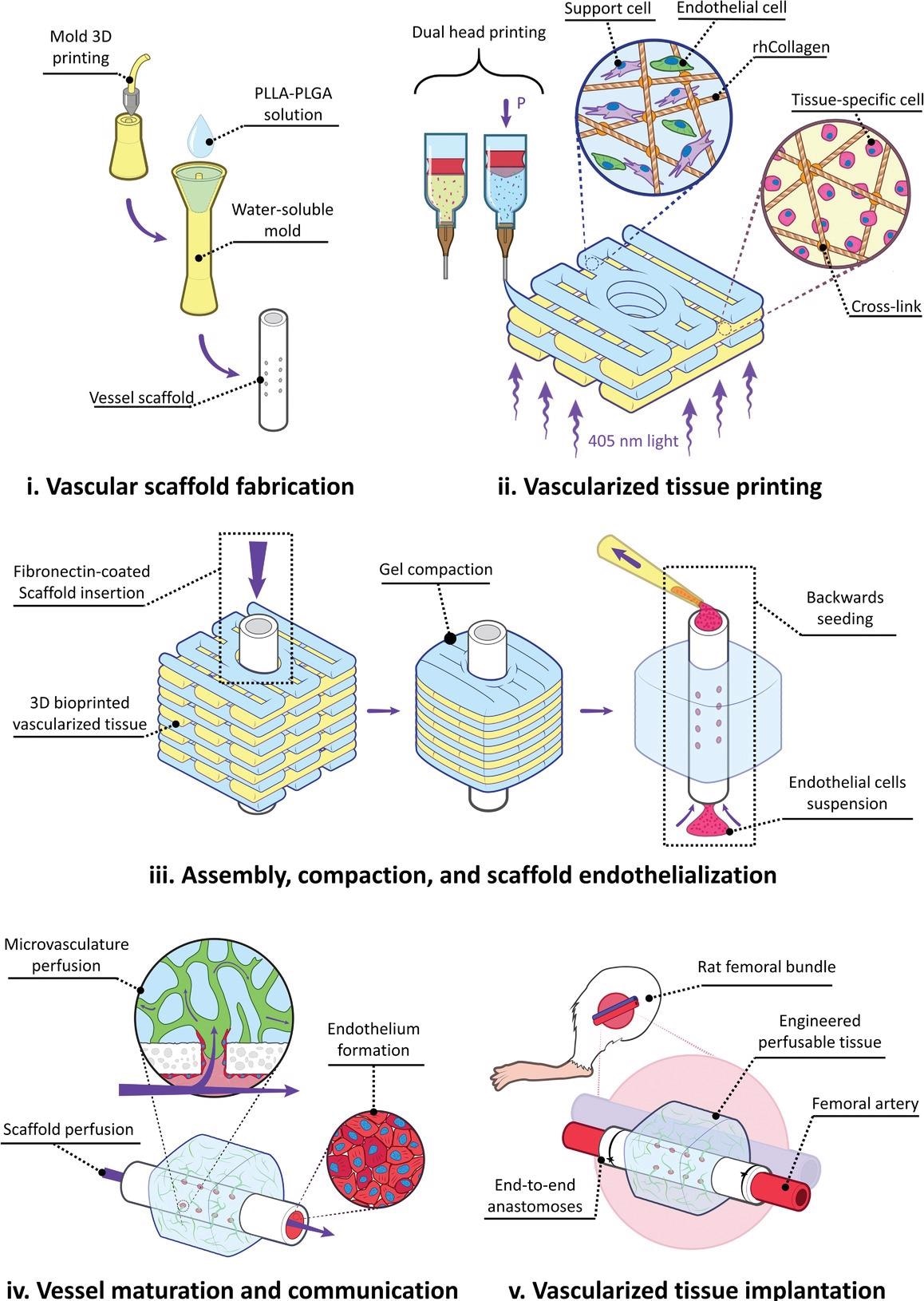

A team of researchers at Israel's Technion Institute of Technology have used 3D printing to recreate life-like complex blood vessel structures capable of supplying blood to tissue implants. The team aims to engineer thick tissue flaps tailored to patients' individual needs.

Image Credit: Hanaphy, P., Everett, H. and Sertoglu, K. (2021) Technion researchers 3D print blood vessel networks for tissue implants, 3Dprintingindustry.com. Available at: https://3dprintingindustry.com/news/technion-researchers-3d-print-blood-vessel-networks-for-tissue-implants-197078

Image Credit: Hanaphy, P., Everett, H. and Sertoglu, K. (2021) Technion researchers 3D print blood vessel networks for tissue implants, 3Dprintingindustry.com. Available at: https://3dprintingindustry.com/news/technion-researchers-3d-print-blood-vessel-networks-for-tissue-implants-197078

Bioprinting techniques are already used to "print" tissues in biomedical research. Living cells are mixed with hydrogels and deposited layer-by-layer on scaffolds to reproduce the desired tissue.

This eliminates the need to place tissue into a patient's limb as it can be permeated by blood vessels prior to transplant. This opens up the possibility of complete customization of tissue prior to transplant and reduces the risk of implant rejection.

A Quick Primer on 3D Printing

3D printing, also known as additive manufacturing, is at the forefront of innovations in engineering, manufacturing, biomedical research and other industries. Whereas 2D printers only reproduce height and width, 3D printers also reproduce depth.

A material, such as plastic, is fed through the printer nozzle, which is itself controlled by a computer. As the nozzle head moves up and down, or side to side, it deposits successive layers of the material which then settles into the desired shape. Almost any shape can be recreated this way.

Bioprinters use the same principle, except the material used is a biomaterial - a 'bio-ink' - made up of living cells. A dissolvable gel or collagen - such as the recombinant human collagen methacrylate (rhCollMA) used by Dr. Ariel Alejandro Szklanny - is used to structure and grow the cells.

Used in this way, researchers such as Dr. Szklanny, working under Prof. Shulamit Levenberg at Technion's Stem Cell and Tissue Engineering Laboratory, can reproduce complex biological structures such as blood vessels.

Working with Complex Biostructures

The cardiovascular system is a common feature shared by vertebrates and invertebrates which has evolved over 600 million years. Its intricate tree-like structure distributes nutrients to tissues and facilitates the removal of cell waste.

Engineering such a complex hierarchical structure remains an unsolved challenge as current techniques focus only on creating self-assembled microvascular structures or mesoscale (>1mm diameter) vessel replacements.1

Tissues that are engineered to be greater than the nutrient diffusion limit require a vascular network that supports the transport of nutrients and waste.

However, Dr. Ariel Szklanny seeded endothelial cells from the inner layer of blood vessels in the body, on a polymeric collagen scaffold. This resulted in the spontaneous formation of vascular structures.

Previous work has shown that self-assembling microvascular networks improve in vitro tissue development and promote vascular integration upon implantation.1

Yet, these studies do not show how to integrate engineered tissues directly into the patient's vascular structure, and they have not considered how the engineered tissue interacts with the host or how engineering only methods focus on elongated tubular structures.

Prof. Levenberg and his team used a novel approach to bridge the gap between micro (<1mm diameter) and mesoscale vascular structures. They utilized 3D bioprinting techniques to reproduce microvessels on vessel-shaped collagen scaffolds.

Working with Collagen Scaffolds

The Technion team bio-printed a self-assembling microvascular network in an extracellular matrix (ECM) protein environment. This structure was connected to a larger tubular vascular scaffold, ready for implantation.

In this arrangement, microvessels receive nutrients from the vascular scaffold, resulting in a tissue unit that contains a functional vascular network.

Hierarchical vascular structures are necessary for reproducing implantable thick tissues. Current techniques rely on mesoscale vessels for implantation or on growing microvascular structures in vitro.

The Technion team is the first to combine micro vessel-shaped structures with 3D printed vascular tissues. Thus, fully hierarchical vascular structures are produced, ready for transplant.

This is a versatile approach that uses human collagen bio-inks and vascular scaffolds for recreating hierarchical structures that can be readily implanted as tissue flaps. This breakthrough represents a major leap in personalized medicine.

References and Further Reading

- Szklanny, A. A. et al. (2021) “3D bioprinting of engineered tissue flaps with hierarchical vessel networks (VesselNet) for direct host-to-implant perfusion,” Advanced Materials (Deerfield Beach, Fla.), p. e2102661.

- Hanaphy, P., Everett, H. and Sertoglu, K. (2021) Technion researchers 3D print blood vessel networks for tissue implants, 3Dprintingindustry.com. Available at: https://3dprintingindustry.com/news/technion-researchers-3d-print-blood-vessel-networks-for-tissue-implants-197078/.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.