Biocomposite materials are being explored for their potential applications in materials science and engineering. A study published in 2021 in the journal Polymers has demonstrated the development of biocomposite materials from one of the most widely grown crops in the world: wheat.

Study: Wheat Biocomposite Extraction, Structure, Properties and Characterization. Image Credit: YRABOTA/Shutterstock.com

What are Biocomposite Materials?

Biocomposite materials are produced from natural instead of synthesized materials such as carbon fiber and glass or epoxy resins. Biocomposites are more sustainable than their synthetic counterparts; they do not require fossil-fuel intensive manufacturing processes or harsh chemical reagents and are disposable. Their biodegradability allows them to be composted at the end of their life. They have comparable mechanical properties to synthetic alternatives.

Biocomposite materials can be fabricated from many natural sources. Hemp, wool, silk, bamboo, hair, and flax fibers can be obtained from different plant and animal sources. Rubber and polyester are commonly used naturally sourced matrix materials.

Plants are the most useful source of biopolymers due to quality, quantity, and availability. However, physical properties of plant materials vary, such as thickness, water solubility, and density. Furthermore, variations in the chemical and physical properties of plant-derived materials such as their degree of crystallization and polymerization make them suitable for biocomposite materials research.

Due to their superior sustainability, biocomposites are also referred to as green composites.

Potential Uses for Biocomposite Materials

Due to their biocompatibility, non-toxicity, and disposability, biocomposites show potential for multiple industries.

They are a focus of research exploring their use as materials for medical devices, furniture, construction materials, packaging, and insulation. These organic-derived materials create vast opportunities for environmental sustainability by replacing artificial plastics and other ecologically damaging materials in common use around the world.

Why Wheat is an Attractive Alternative for Biocomposite Materials

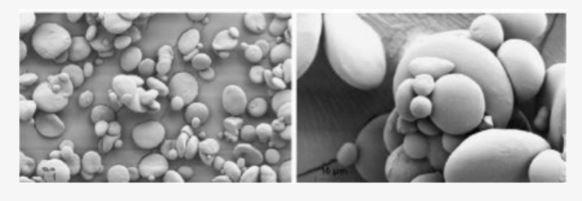

Wheat is a cheap, widely cultivated crop. There are many elements that make wheat an attractive target for biocomposite materials research: wheat gluten, starch, and fiber all have mechanical and physical properties that make them crucial to the global biopolymer industry.

Morphology of native wheat starch. Image Credit: Mohammed, A.A.B.A et al, Polymers

Wheat fiber develops thermal and mechanical properties as a result of different matrices, and gluten is biodegradable, non-toxic, elastic, and water-insoluble.

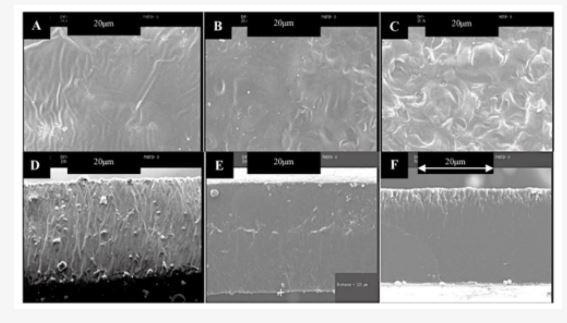

Glycerol increases the water vapor permeability and elongation of wheat films. Wheat starch is used as a biopolymer film, either with or without additional fillers. Wheat fiber is used as a reinforcement filler for the material matrix.

The abundance of wheat and its utilization in the food and biofuel industries also creates a lot of waste. This makes the wheat byproducts a cheap, non-toxic, sustainable, and endlessly renewable source of important composite materials.

Fabrication of Wheat Biocomposite

Biocomposite materials are fabricated by reinforcing natural lignocellulosic fibers with polymer composites. The mechanical properties of reinforced fiber composites depend on four factors: fiber type, content/loading, orientation and dispersion, and adhesion between fibers and the polymer matrix. This results in good levels of adhesion, ensuring stress transfer from matrix to filler.

Products based on wheat gluten are produced by extrusion, compression molding, or casting. The inclusion of hydrophilic plasticizers is essential for film flexibility and thermal processing and results in mechanical property changes.

Furthermore, adding protein to the biocomposite also improves mechanical properties.

Morphology of biopolymer-based wheat starch (A–C) represent wheat starch biopolymer surface with 0, 20 and 50% of Glycerol, respectively, while (D–F) represent wheat starch biopolymer cross-section with 0, 20 and 50% of Glycerol, respectively. Image Credit: Mohammed, A.A.B.A et al, Polymers

Many studies have been carried out on wheat biocomposites. Techniques such as mixing and compression molding, solution-casting, and extrusion and injection molding have been explored for the fabrication of these important biomaterials. Various polymers have been explored to strengthen wheat biocomposites including natural rubber, modified potato starch, polylactic acid (PLA), and polyester resin.

Using PLA produced the highest tensile strength and tensile modulus.

Furthermore, incorporating wheat fibers into wheat gluten has been explored by Monta et al. The fibers were prepared by impact milling, ball milling, and cut milling. Incorporating 11.1% of impact or cut milled wheat fiber, and 1.2% ball-milled fiber, increased the biocomposite’s mechanical properties.

There have been numerous research studies that have all demonstrated mechanical property increases that attest to the suitability of wheat biocomposites to create strong, sustainable, naturally-derived materials. The results of these studies are extremely promising.

The Future

The abundance of plastic and synthetic materials presents a huge challenge to humankind. They cause environmental damage on a massive scale, clogging our oceans and landfills. Furthermore, the emissions created by their manufacture contribute significantly to global warming.

Biocomposite materials provide an alternative, creating truly sustainable packaging, construction materials, and other commercially and industrially important products.

Due to the abundance of crops and non-toxic byproducts from the food and bioethanol industries, wheat biocomposites present an opportunity for the materials industry. However, more research is needed into these materials if they are to become truly commercially viable in the near future.

Reference

Mohammed, A.A.B.A et al. (2021) Wheat Biocomposite Extraction, Structure, Properties and Characterization: A Review [online] Polymers 13(21) 3624 | mdpi.com. Available at:

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.