The manufacture of highly sensitive, reliable humidity sensors is a key research focus for various industries. Published in the journal Materials, a paper has demonstrated the development of a device based on porous gadolinium aluminate nanomaterials.

Study: Porous Nanostructured Gadolinium Aluminate for High-Sensitivity Humidity Sensors. GzP_Design/Shutterstock.com

Humidity Sensors: Importance and a Brief History

Humidity is an important environmental parameter for numerous industrial sectors. These sectors include food processing, the pharmaceutical industry, the HVAC industry, biomedical research, microelectronics, agriculture, structural health monitoring, and meteorology. Humidity is defined as the amount of water vapor in an environment, mainly air.

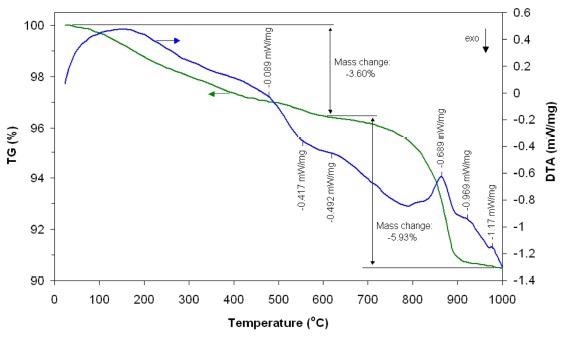

TG-DTA curves of gadolinium aluminate (before heat treatment). Image Credit: Doroftei, C & Leontie, Materials

There have been numerous approaches used over the years to monitor relative humidity levels in an environment, with varying degrees of success. Examples of techniques include hygrometers, sling psychrometers, and chilled mirror hygrometers.

These are indirect methods that measure condensation and evaporation to measure relative humidity, but they suffer from drawbacks such as poor accuracy limited range. These drawbacks demanded the development of more accurate and sensitive methods.

The invention of the transistor led to the development of electrical humidity sensors which measure changes in electrical resistance caused by humidity, but these too suffered drawbacks in terms of limited accuracy, poor stability, and hysteresis. The first thin-film polymer-based humidity sensor was developed in the 1970s, providing greater reliability and addressing the shortcomings of previous designs.

Recently, research has focused on ceramic sensors due to their cost-effectiveness and superior chemical and thermal stability. These sensors detect humidity in two ways: the resistive electrical method and the capacitive electrical method.

More recently, there has been increasing focus on the perovskite materials for their application in environmental humidity sensors. Additionally, there is a need for materials that are environmentally friendly to reduce carbon footprints, waste, and pollution.

Using Perovskite Materials for Humidity Sensors

Perovskite materials, which have been studied extensively for energy harvesting and supercapacitor devices, have shown increasing potential for humidity sensors. Lanthanide-doped aluminates have been demonstrated to be an important class of these materials from an applicative point of view.

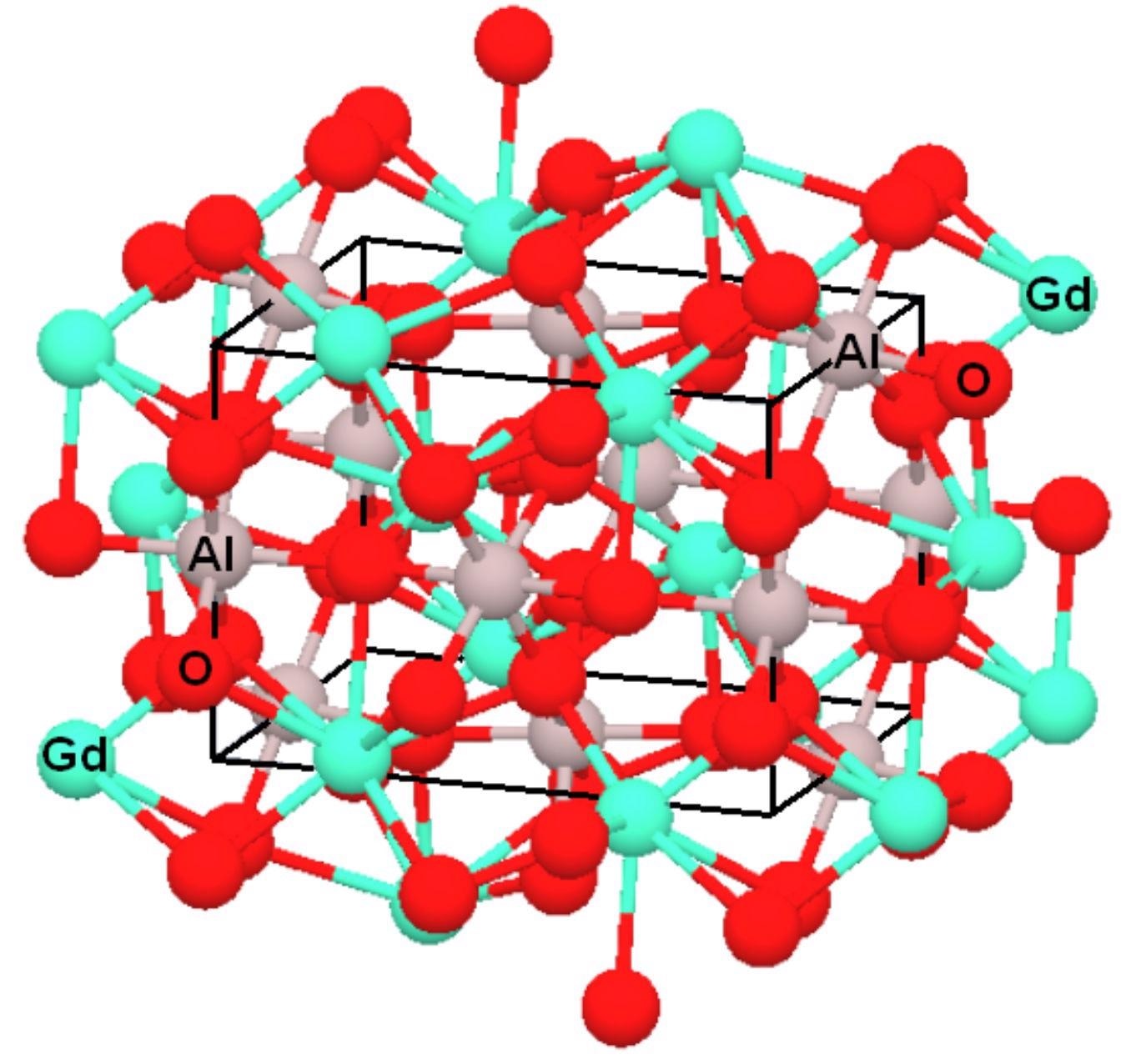

Spatial structure and unit cell of GdAlO3 perovskite. Image Credit: Doroftei, C & Leontie, Materials

In the research published in Materials, the synthesis of gadolinium aluminate perovskite was presented and its application for humidity sensing devices was explored. The method used to synthesize the perovskite material was the sol-gel self-combustion process. Self-combustion produces gadolinium aluminate at vastly reduced temperatures compared to classical synthesis methods.

Polyvinyl alcohol was utilized as a colloidal medium. Ammonium hydroxide solution was added until the pH was 8, which produced a “soil” of metal hydroxides which were dried and underwent a self-combustion process to obtain a nanocrystalline powder. Organic residues were removed by being calcined for 30 minutes at 500 oC.

The sensing elements were then pressed into disks (both capacitive and resistive elements were prepared in this manner) which were 17mm in diameter and 2mm thick. Screen printing was used to deposit porous silver electrodes onto these disks. Capacity and electrical resistance values were determined by impedance analysis.

The gadolinium aluminate sensors were then inserted into a thermostat chamber with different levels of humidity at a temperature of 25oC to test their measuring ability at room temperature. Results of the experiments demonstrated that humidity levels significantly influence the capacitive and resistive properties of the sensors, with a capacity increase of approximately ten thousand times and a resistance decrease of about eight thousand times as the relative humidity increased from 0-98%.

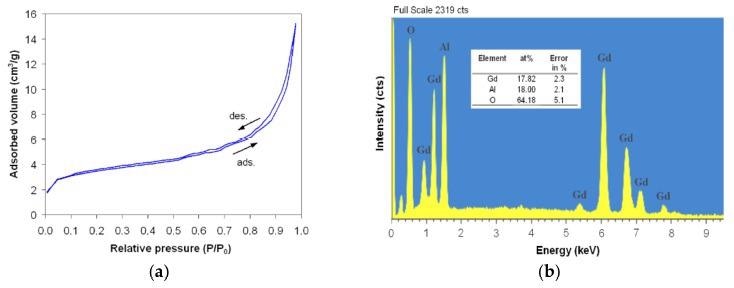

N2 adsorption/desorption isotherms (a) and EDX spectrum with the analyzed elements (b) for gadolinium aluminate powder, heat-treated at 1000 °C for 7 h. Image Credit: Doroftei, C & Leontie, Materials

Additionally, the sensors displayed hysteresis levels of under 3%, the linearity of log C and Log R vs. RH was good at all working frequencies, and the gadolinium aluminate perovskite displayed an absorption response time of approximately 180 seconds and a desorption response time of 230 seconds.

The longer desorption response time can be explained by the microporous structure (pore distribution and size) of the material influencing different water vapor adsorption/desorption rates.

What Does This Mean for the Future of Humidity Sensors?

The demands of industry increase the need for materials with suitable electrical properties, response times, mechanical properties, stability, and other characteristics that improve the functionality of devices. The relative humidity is a crucial parameter for several sectors, and sensors designed with enhanced properties, accuracy, and sensitivity, are needed.

Perovskites have shown promise for applications in humidity sensors due to their superior electrical and physical properties.

The sol-gel self-combustion process set forth in the research paper produced gadolinium aluminate which possesses a perovskite structure at a much lower temperature than classical methods, saving on energy use and making the process much more environmentally friendly. This research demonstrates that gadolinium aluminate can be used for highly sensitive humidity sensors.

Further Reading

Doroftei, C & Leontie, L (2021) Porous Nanostructured Gadolinium Aluminate for High-Sensitivity Humidity Sensors [online] Materials 14:22 | mdpi.com. Available at: https://www.mdpi.com/1996-1944/14/22/7102

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.