Noise pollution is an ever-present environmental problem in urban areas. To reduce the negative health effects it induces, sound-absorbing materials are commonly employed, but their performance at low frequencies needs to be improved. To this end, a paper published in ACS Omega has investigated the development of ceramic sound-absorbing materials enhanced with graphene oxide.

Study: Enhanced Sound Absorption Properties of Ceramics with Graphene Oxide Composites. Image Credit: Peter Hermes Furian/Shutterstock.com

Addressing the Harm Caused by Noise Pollution

Environmental noise pollution is a consequence of modern urban society, with studies indicating that it is as harmful as air and water pollution to human health. Noise pollution has serious psychological and physical impacts on human populations.

Noise pollution can cause sleep disturbance, stress, high blood pressure, loss of hearing, loss of concentration, and irritability. It also affects productivity. Furthermore, studies have linked noise pollution to endocrine effects, cardiovascular disease, and diabetes.

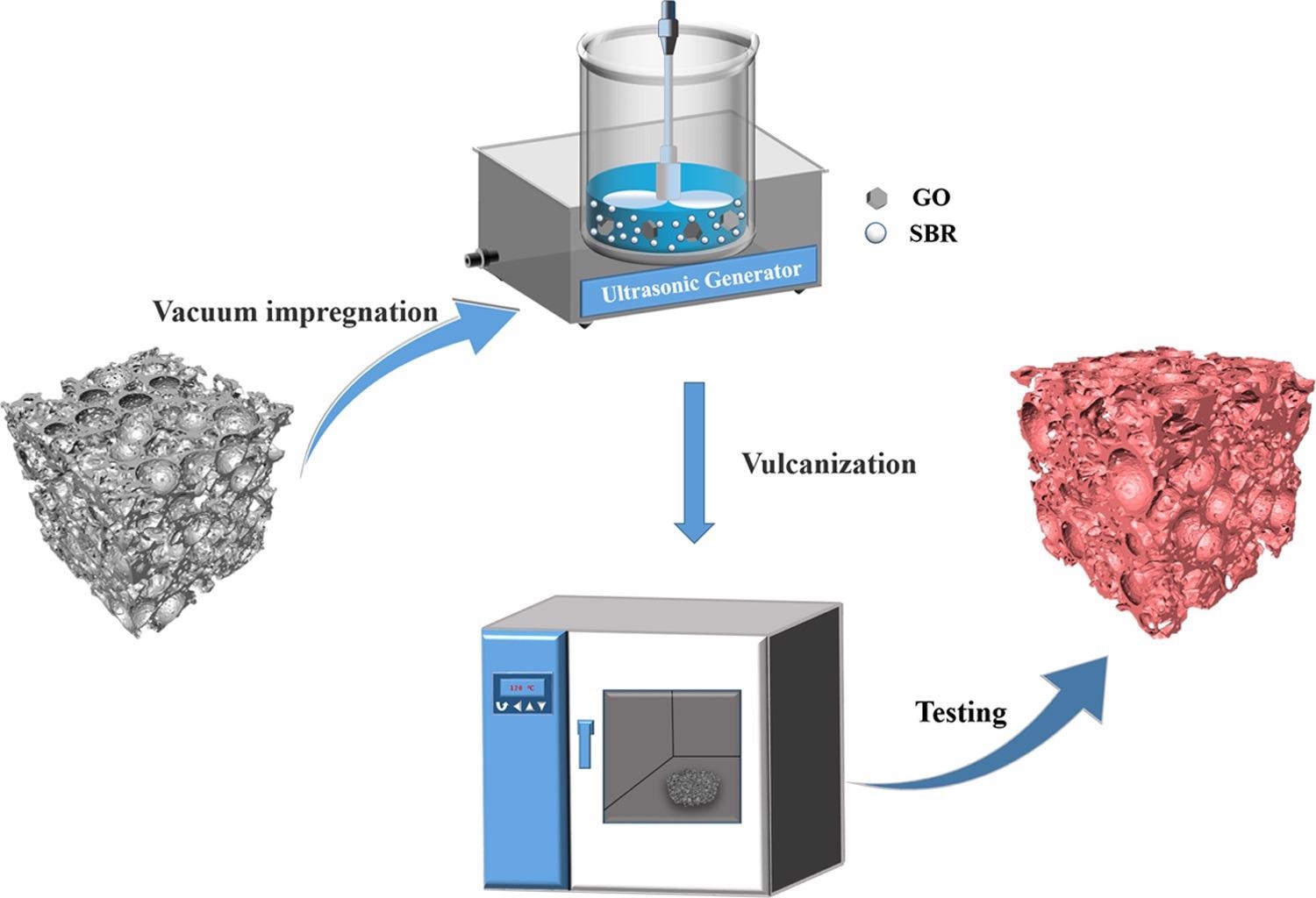

Schematic diagram of the synthesized GO-SBR structure in the porous ceramic skeleton. Image Credit: He, C et al., ACS Omega

Aside from sudden, loud noises such as construction activities and vehicles backfiring, low-level and low-frequency noise pollution from traffic and neighborhood noises can cause long-term effects on human health. The ubiquitous nature of noise pollution is a constant challenge for city planners and public health officials.

To reduce the potentially deleterious effects of ongoing noise pollution, soundproofing and sound-absorbing materials are commonly employed in domestic and commercial settings. City governments also enact local laws and regulations to reduce the instance of noise pollution, but these do not sometimes go far enough: pollution from everyday noise affects millions of people worldwide.

Designing Acoustic Absorbing Materials for Low Frequencies

The demand for acoustic absorbing materials has increased in recent years, with significant research focusing on improving the design of materials to combat noise pollution. Traditional materials used in acoustic absorbing materials include polymers foams, metallic foams, and porous ceramics. Although these materials perform well overall, they face challenges with absorbing low and middle frequencies.

Several strategies have been proposed to improve the low and middle-frequency absorption of commonly used materials. Many researchers have attempted to solve this issue by incorporating different materials into acoustic absorbing materials. Carbon-based materials are an attractive choice for fillers due to their superior physical properties and large specific surface area.

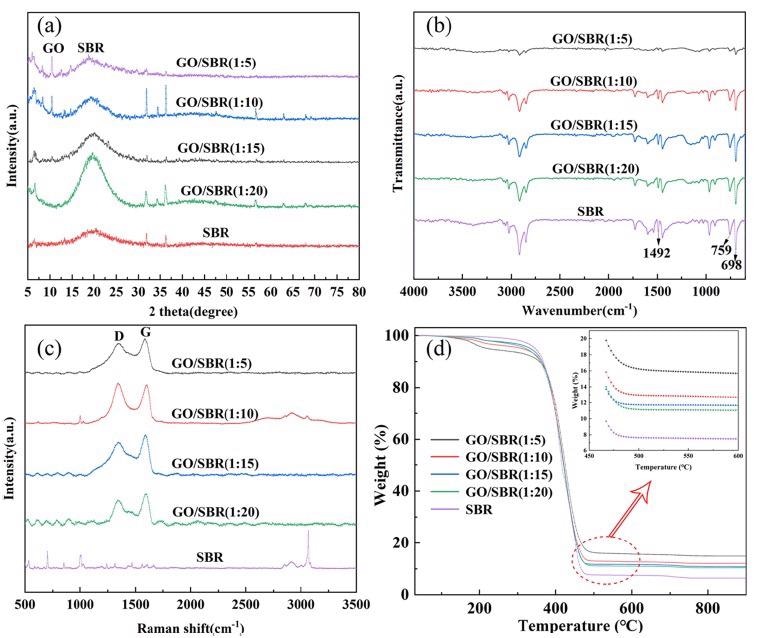

(a) XRD patterns, (b) FT-IR spectra, (c) Raman spectra, and (d) TGA curves of GO/SBR composite films with different contents of GO. Image Credit: He, C et al., ACS Omega

Studies on Graphene Oxide to Enhance Sound Absorption

Studies have recently been carried out into the use of graphene oxide as a composite material to improve the absorption of traditional materials. Freeze-drying and directional freezing has been used to manufacture composite polymer foam materials with well-arranged graphene oxide layers. Porous composite foams have been developed which take advantage of the electrostatic repulsive force of activated potassium hydroxide and graphene oxide.

Further studies have developed sound-absorbing materials based on interlinking sheets of graphene oxide supported by a melamine network with a grid-like structure. Compared with melamine foam, this stratified composite material displayed a 72.7% improvement at 500 Hz. The material improved the thermal and viscous effects of the material and its material damping effect. Sound pressure waves are absorbed via the porous network’s flexible motion.

Coating Ceramic Materials with Graphene Oxide to Create Composite Materials with Enhanced Acoustic Absorption Properties

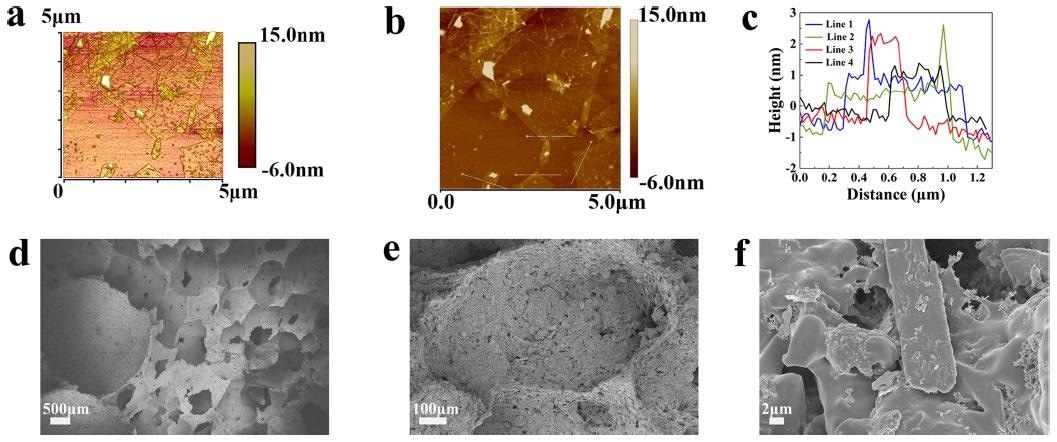

The research paper published in ACS Omega has demonstrated the development of porous ceramic materials with superior low and middle-frequency acoustic absorption. Previous work done by the authors created materials with hierarchical porous structures which possess micro- and nanopores. A twice foaming method was used by the authors to prepare the material, and it exhibited a good response to frequencies between 200 and 2000 Hz.

However, the authors identified room for improving low-frequency absorption, which laid the basis for their current work. The team came up with a novel graphene oxide/styrene-butadiene rubber coating. This was applied to porous ceramics as a film. Homogenous suspensions were obtained by ultrasonication and stirring, and the composite material was introduced by atmospheric vulcanization and vacuum impregnation methods. This optimized the ceramic’s internal pore structure.

(a) Three-dimensional AFM images of the GO aqueous solution; (b) 2D morphology of the GO aqueous solution; (c) height statistical line diagram; and (d−f) SEM images of the composite porous materials with pure SBR. Image Credit: He, C et al., ACS Omega

The composite graphene oxide/rubber film-coated porous ceramic materials underwent a series of tests to determine their sound absorption properties. The composite material performed well, exhibiting a 30.4% improvement in its sound absorption coefficient compared to untreated porous ceramics at a range of 200-800 Hz. The noise reduction coefficient of the composite material was enhanced by more than 15.4%.

The results of the study demonstrated the improvement of low and medium frequency acoustic response in the composite graphene oxide/rubber/porous ceramic material by introducing a flexible coating onto a rigid framed sound absorption material. Additionally, the low thermal conductivity of the material was observed, which could make it an attractive material for acoustic absorption in buildings.

Further Reading

He, C et al. (2021) Enhanced Sound Absorption Properties of Ceramics with Graphene Oxide Composites [online] ACS Omega | pubs.acs.org. Available at: https://pubs.acs.org/doi/full/10.1021/acsomega.1c03362

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.