A new breakthrough in printing metal using additive manufacturing with periodic layer rotation is explored in the journal Materials. Unlike traditional machining methodologies, additive manufacturing (AM) in the metal production process has the privilege of manufacturing complex shapes and allows customizable production.

Study: A Study on the Mechanical Properties of an Automobile Part Additively Printed through Periodic Layer Rotation Strategies. Image Credit: Zyabich/Shutterstock.com

Nevertheless, anisotropy of the macrostructure happens as a consequence of AM processing parameters such as design processes, melting, fusion, and condensation of the powdered material.

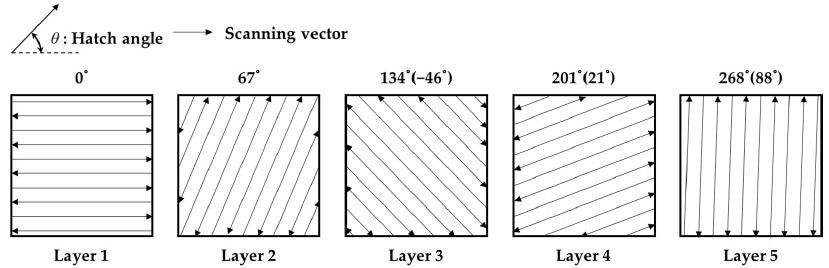

The scan direction determines the macrostructure anisotropy, which is conveyed as orthogonal anisotropy whenever a single layer is piled in one path. The classical lamination theory is used here to simply superimpose the personal orthotropic layers. The authors used this strategy to determine whether the mechanical characteristics of the commodity are isotopically expressed using a periodic layer rotation strategy.

AM and the Idea Behind It

The basic idea behind additive manufacturing (AM) is to generate the desired shape straightforwardly from 3D digital modeling data. Components are stacked layer-by-layer to develop products, as opposed to traditional machining operations such as casting or cutting.

Because of this fundamental process difference, new procedures (such as configuration for AM) in the additive product development stage can resolve the drawbacks of existing conventional manufacturing techniques and easily control the AM process. As a result, AM is gaining popularity as a desirable fabrication technique for the design and manufacture of high-performance components.

Schematic of 67° rotation increments of a layer using a raster scanning strategy. Image Credit: Yang, M., et al., Materials

Different Process to Produce Metal AM

Metal AM has a great deal of freedom in molding, including such custom designs; nevertheless, mechanical, and physical properties of the device may suffer due to anisotropy of the configuration depending on the nature of the production process.

The DED method is additively produced by depositing in a local area, whereas the PBF process is a molding technique that involves melting and stacking a flat powder area with the preferential thermal energy of a sensor. The PBF process, in specific, is widely used for the AM process as a typical example of metal AM in manufacturing products.

Limitation of Additive Manufacturing

The substance has a thermal behavior during melting and crystallization, and the solidified microstructure has directionality based on the heat source's motion path. This has an impact on the alloys' mechanical properties and microstructure.

As a major occurrence, residual stress induces deformation, resulting in product distortion or damage. The anisotropic property of the good or service is the directional cues of the microstructure. This issue leads to directional inaccuracy in the good or service or affects the dynamic or static behavior of a structure, adding another parameter to consider during the design stage.

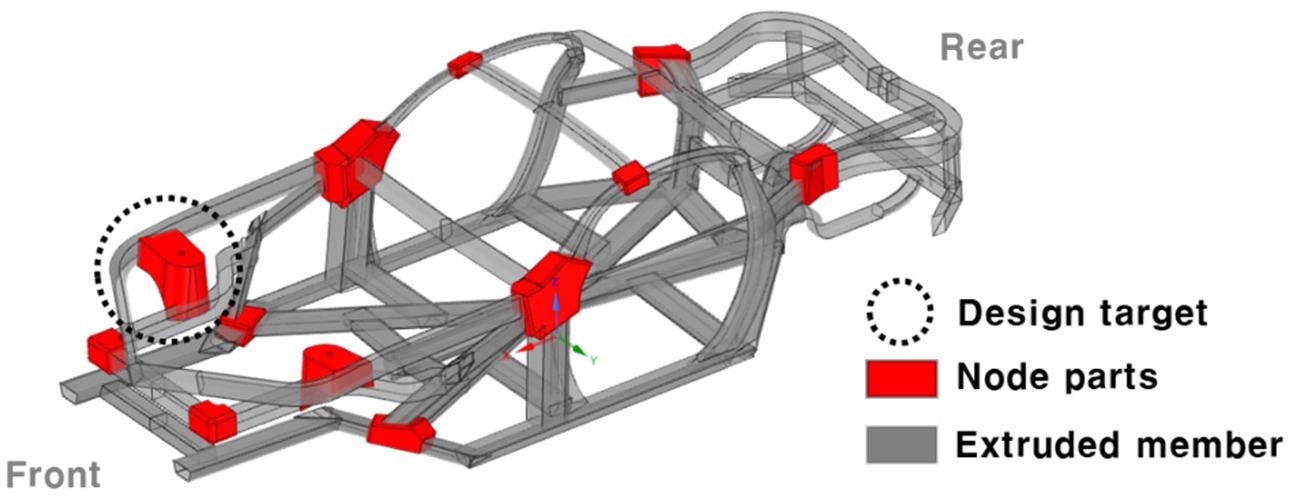

Space frame and node parts of the vehicle. Image Credit: Yang, M., et al., Materials

This behaves as a design restriction and reduces the usefulness of metal AM with high material properties. To address these issues, a periodic layer rotation strategy was used to repress the material's directionality.

Research Process with Sporadically Rotating Layers Technique

Researchers use the AM technique of sporadically rotating layers to evaluate the material characteristics of the products numerically. The intrinsic strain method has been widely used to simulate additive processes. This methodology is very consistent with the approach used in traditional lamination theory to categorize composite actions.

The PBF process, like the methods used to make composite laminates, is a layer-by-layer manufacturing technique. The complete system is layered in both situations, and anisotropy is induced. The hatching series of the AM process has the same impact as the fiber direction of the composite in this case. As a result, the properties of the material at the product level can be inferred using the classical lamination concept.

The Research Result

AM created a shock absorber handrail for a vehicle to see if the mechanical characteristics can be decently recognized isotropic. The product's compressive strength and vibration tests were compared to the finite element analysis and experimental data. As a result of a comparison, it was stated that the item was macroscopically isotropic because the load-displacement diagram and fracture location, and the resonant frequencies and mode shape, coincided.

Advantage of the Car Printing Using AM Methods

It demonstrates that stress exceeds tensile in the inner zone of the upper and lower flanges. The similar plastic strain findings confirm that the phenomenon was highest in the inner flange area. The experimental data and the FE analysis model had very similar modal forms.

The error in the natural frequency findings was confirmed as the higher-order method ended; nevertheless, it was an essential mistake that showed up because the utterance of components was limited due to FE modeling character traits.

The natural frequency precision at higher orders might be better expressed when sculpting with a larger collection of pieces or more than a second-order element. As both a result, it was affirmed that the outcomes of the FE model's dynamic analysis, toward which isotropic properties of the material were implemented, and the natural frequency and modal form of the experimentations were in good agreement.

References

Yang, M., et al. (2021). A Study on the Mechanical Properties of an Automobile Part Additively Printed through Periodic Layer Rotation Strategies. Materials 2022, 15(1), 70; Published: 22 December 2021. https://www.mdpi.com/1996-1944/15/1/70

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.