In a recent study published in the journal Ceramics International, researchers from China analyzed a new laser transmission-based welding method to enhance the welding strength between ceramic surfaces and highly transparent polymers.

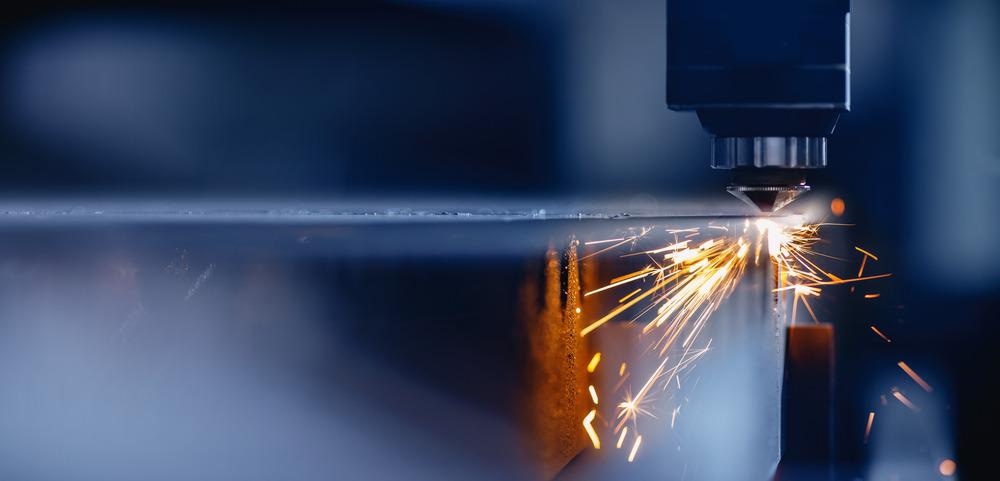

Study: Laser transmission welding of PMMA to alumina ceramic, Image Credit: Parilov/Shutterstock.com

The researchers used alumina as the ceramic substrate and poly (methyl methacrylate) (PMMA) as the transparent polymer. Before laser transmission welding, the ceramic surface was pulse laser pretreated to form blind holes.

When the polymer was heated using the laser transmission welding method, a temperature gradient was generated from the ceramic-polymer interface towards the depth of blind holes, which facilitated the formation of air bubbles in the polymer melt pool. This riveted interlocking between blind holes and polymer bubbles increased the welding strength of the ceramic polymer composite. Further, they analyzed the effect of continuous laser power, continuous laser scanning rate, and the blind hole microstructure size on molten polymer flow and weld strength.

Ceramic-Transparent Polymer Composites

In the field of biomedical applications, ceramics are excellent materials due to their strength, hardness, corrosion resistance, biocompatibility, thermal stability, and inertness. However, the medical monitoring systems often require transparent polymer windows, which cannot be obtained from opaque ceramics. Thus, there is a necessity to develop a method to achieve high strength welded ceramic and transparent polymer composites.

Among various welding processes, laser transmission welding offers fast, precise, non-contact, small heat-affected zone, minimum waste generation, and different complex shape handling approaches. Many studies have shown that almost all thermoplastics and their reinforced polymers can be welded with light to heavy metals and alloys, namely, aluminum, magnesium, steel, titanium, and tungsten. However, biocompatible ceramics such as alumina (Al2O3) are heat resistant, which needs an additional process for better weld strength. Other than the selection of the welding process, the surface pretreatment of polymer and ceramics also significantly affects the durability and reliability of the finished welded product.

About the Study

In this study, researchers developed a 3D transient finite element model using ANSYS software to simulate the distribution of flow field, velocity field, flow velocity field in the weld, and analyzed the flow process of the polymer melt flowing into the blind holes on the pretreated ceramic surface, which trapped air in the polymer to form bubbles.

The team first procured alumina and PMMA plates with dimensions of 40 x 20 x 1 mm and 40 x 20 x 2 mm, respectively, which were ultrasonically cleaned in an alcohol bath.

After that, a nanosecond pulsed laser with a wavelength of 1064 nm, maximum power of 20 watts, frequency of 20 kHz-80 KHz, a beam spot diameter of 20 µm, and traverse speed of 7000 mm/s was used to regulate blind hole microtextures on the surface of the ceramic specimen at room temperature.

More from AZoM: Role of Laser Emitters in Industrial Food Sorting

Finally, a continuous semiconductor-based laser with an output wavelength of 980 ± 10 nm, a pulse width of 0.3-20 ms, an output power of 130 watts, frequency of 500 Hz, and spot diameter of 0.9 mm was used for laser transmission welding.

The alumina and PMMA plates were lap-jointed in which the alumina plate was at the bottom to absorb heat and transfer it to the PMMA plate until the polymer started to melt. Owing to gravity, capillary force, buoyancy, and clamping force, molten PMMA started to flow into the ceramic blind holes and trapped air to form solidified PMMA bubbles, riveting the two plates.

Observations

The scanning electron microscopy (SEM) image of the joint section between the alumina ceramic and PMMA showed that PMMA filled the blind holes of 0.168 mm depth and alumina ceramic residues were deposited at the bottom of the hole. Also, the ceramic surface of the remelting layer had a convex structure with increased surface roughness.

Under fixed laser power and moving rate, the strength of the joint increased with the increase in the depth of the blind hole owing to increased laser absorption of the ceramic material from the multiple reflections of the continuous laser on the inner wall of the blind holes. However, above a blind hole depth of 0.168 mm, the weld strength started to decrease due to a decrease in the mechanical stability of the ceramic plate.

The thermal imaging results showed the temperature of most regions is below the PMMA decomposition temperature of 570 K, but a very small region in contact with the ceramics achieved temperature up to 600 K. However, it had a negligible impact on the flow rate of the polymer.

Conclusions

In this study, researchers laser transmission welded alumina ceramic and PMMA transparent polymer. The mechanical riveting between blind holes on the pretreated ceramic surface and solidified air-trapped PMMA bubbles enhanced the weld strength. The depth of blind holes up to 0.168 mm increased the weld strength due to higher heat absorption. However, further increases in the depth had adverse effects. Hence, laser transmission welding is a promising welding method for ceramic and transparent polymer composites.

Reference

Liu, H., Liu, H., Xu, W., Wang, H., Wang, X., Laser transmission welding of PMMA to alumina ceramic, Ceramics International, 2021, ISSN 0272-8842,

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.