3D printing is a technology with enormous potential for the construction industry. Whilst there has been plenty of focus on printing entire structures, the idea of printing individual construction elements such as clay bricks is a new area of research. A new paper published in Sustainability has explored the potential of using this innovative technology for this purpose.

Study: The New Boundaries of 3D-Printed Clay Bricks Design: Printability of Complex Internal Geometries. Image Credit: andrey_l/Shutterstock.com

3D Printing: Changing the Face of the Construction Industry

Humankind has built structures in largely the same way for centuries. Conventional construction techniques are labor and resource-intensive, take a relatively long time, and cause greenhouse gas emissions and waste. The problems with sustainability that the construction industry faces have, in recent decades, facilitated the need to find alternative construction technologies.

Of all the technologies that are currently being developed as part of the 4th Industrial Revolution, additive manufacturing (3D printing) has shown significant promise for the construction industry. 3D printing is low-cost and has advantages in terms of sustainability and the ability to tailor printed parts to a specific application.

Several projects have been conducted in recent years to explore the feasibility of 3D printing for the modern construction industry, with buildings currently being developed worldwide. The main focus is on fully printing buildings out of sustainable, printable materials such as concrete. In Texas, the world’s first 3D-printed neighborhood is currently under development.

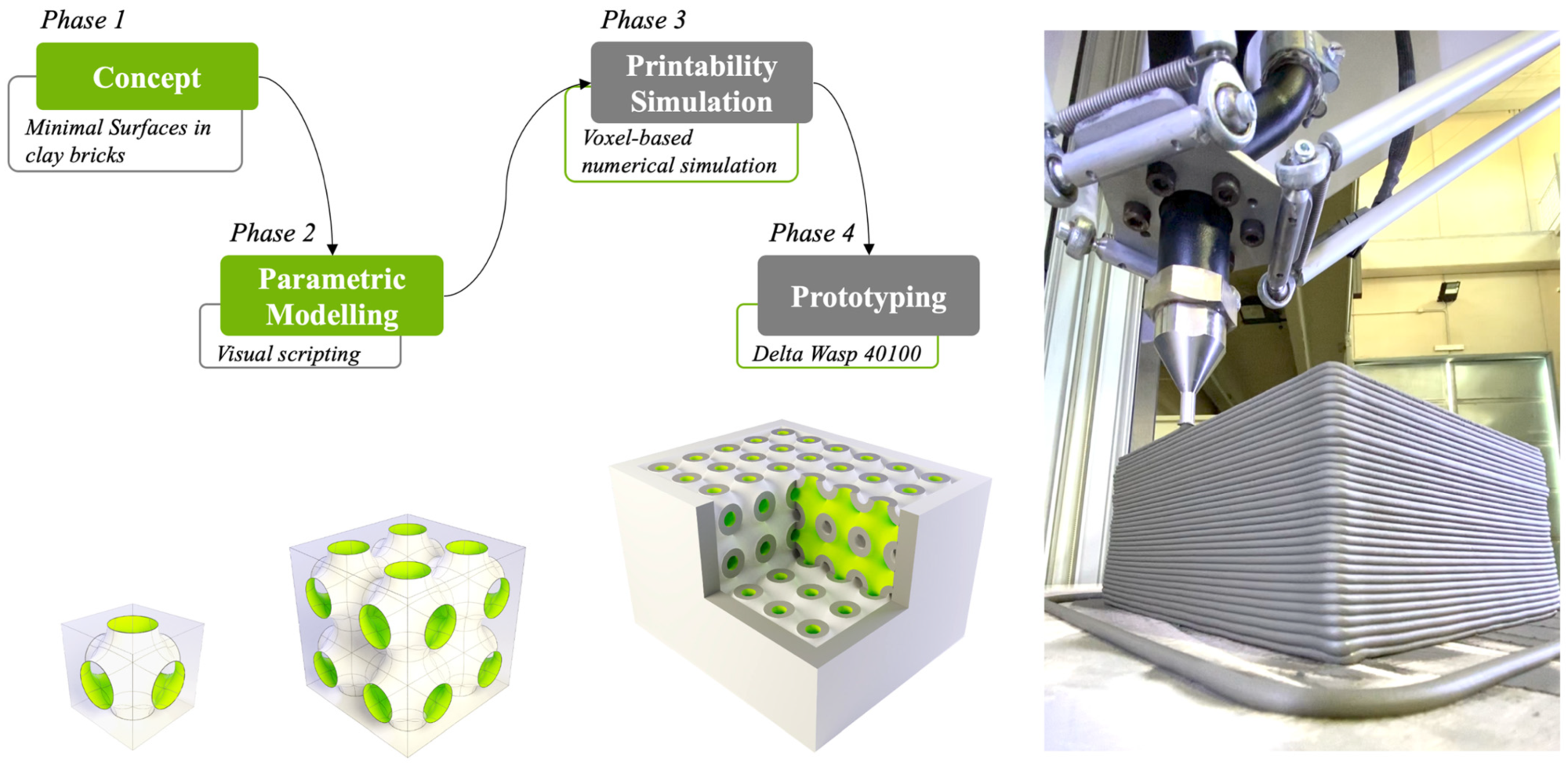

Flowchart of the four phases of the proposed methodology. Image Credit: Sangiorgio, V et al., Sustainability

3D Printing Clay for Architectural Components

Recently, the potential for producing small components out of sustainable 3D printed clay has been explored. Companies and research institutions have investigated the use of these materials in the architecture sector. The Institute for Advanced Architecture has investigated the use of raw earth in constructing building components with their Terra Performa and Digital Abode projects.

Other recent research applications of 3D printing for the prefabrication of small components can be classified into three groups. These are building components for cladding and sunshades, non-structural wall and division bricks, and non-structural brick vaults. Institutions such as the University of California, Berkeley, have been involved in research in the area. In the case of non-structural and division brick design, research has focused on realizing complex external geometries to produce components with multifunctional behaviors.

Whilst there has been growing research focus on exploring external shape freedom, there have been few studies on 3D printing clay components with diverse internal configurations. There have been preliminary investigations on the energy and mechanical properties of printed components (such as bricks) which consider different simple internal geometries.

Peters et al. have argued that 3D printed bricks are promising due to the ability to create structures with different shapes and sizes of air pockets and embed them into walls. Studies have designed, printed, and evaluated structures which only possess a regular internal configuration. Complex shapes which are difficult to print have remained largely unexplored. In the current literature, exhaustive studies which explore the design of complex internal configurations and the limits in printability are missing.

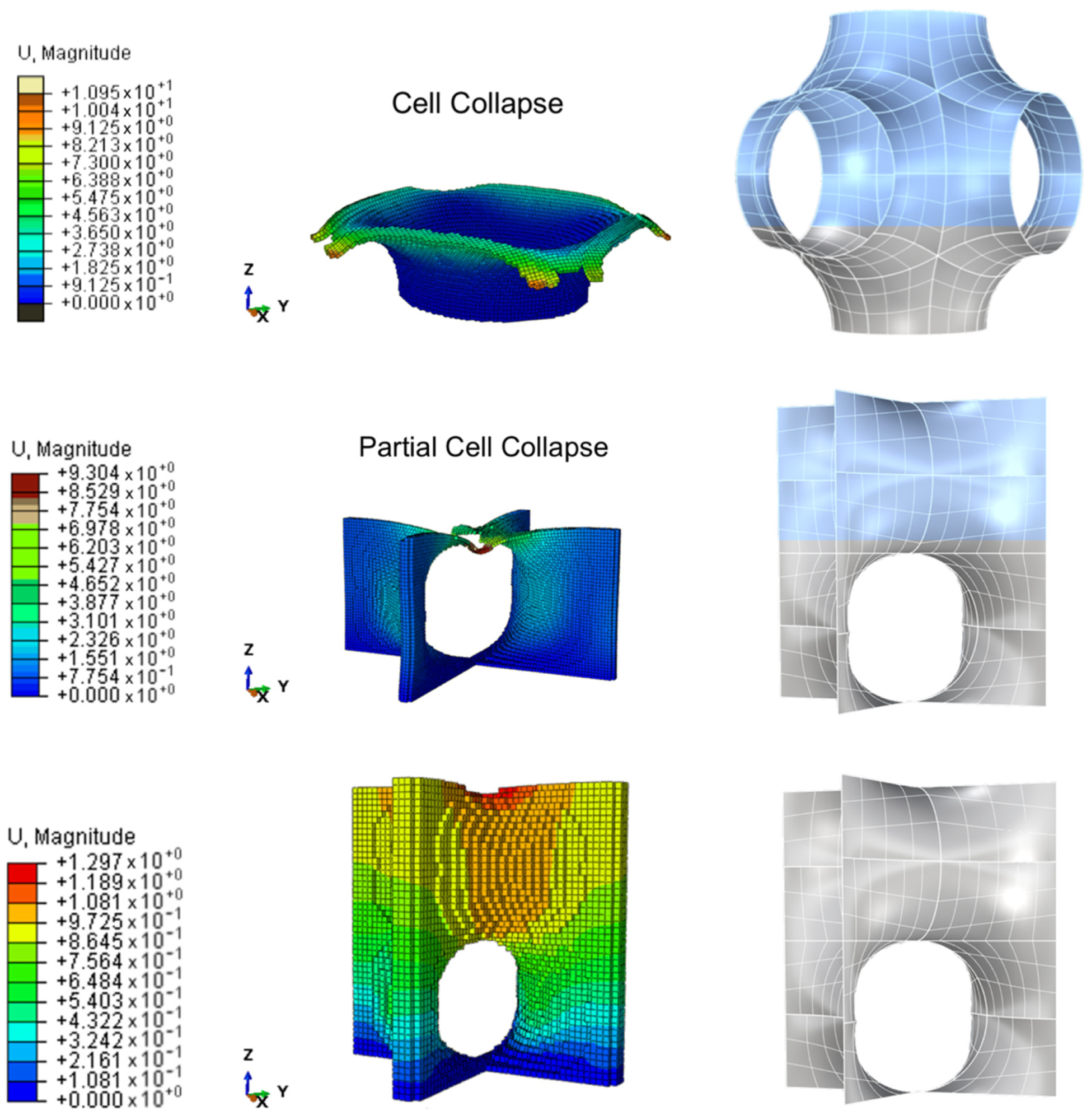

Three examples of the FEM analysis results: collapse, partial cell collapse, and perfectly printable. Image Credit: Sangiorgio, V et al., Sustainability

The Paper

The paper published in Sustainability has explored the development of novel 3D-printed clay bricks with complex internal geometries. The conception, design, and prototyping of these extrusion-printed architectural components have been proposed by the authors. The approach proposed in the paper overcomes the current limitations of 3D printing, moving beyond simple internal geometries.

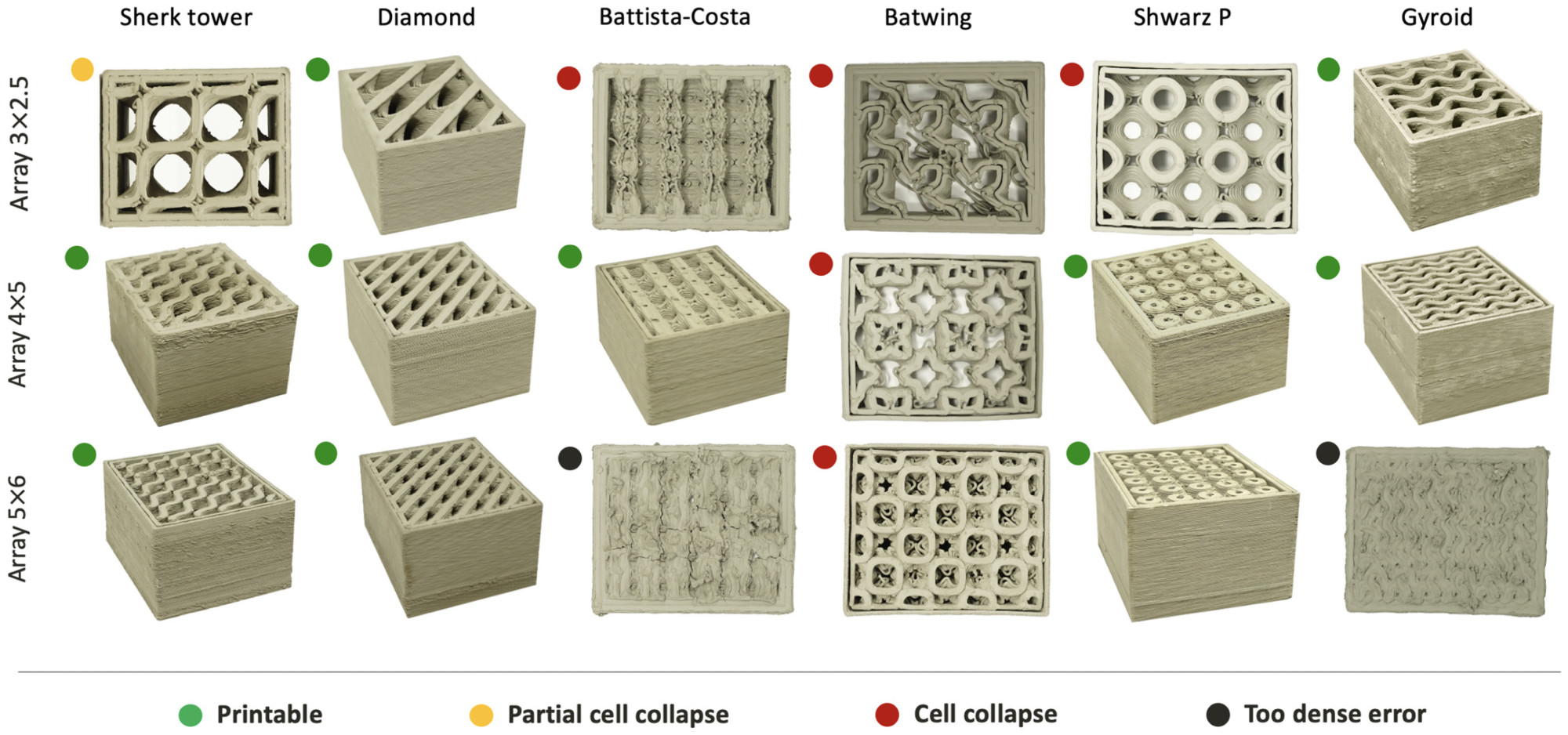

The authors produced components with a classical rectangular brick shape and developed the internal geometries from the starting point of well-known periodic minimal surfaces. A periodic minimal surface locally minimizes its area. The geometries were chosen based on their well-documented mechanical properties and efficient energy absorption. The authors identified the most effective internal brick shape by considering different typologies and configurations. A total of 18 parametric models were analyzed.

The printability of selected geometries with clay materials was fully investigated using finite element method simulations. Numerous printing tests were conducted to validate these simulations. Additionally, the optimal printing configuration was investigated. Thus, an effective realization of the printed bricks was reached.

Furthermore, the novelties of the research were threefold: a novel methodological approach based on four phases, a novel conceptual design of a complex brick structure that can be 3D printed and exploit minimal internal surfaces, and the discussion of principal printing errors and how to overcome any drawbacks.

Prototyping and 3D printing of the 18 bricks and specification of the results in terms of too dense error, collapse, partial cell collapse, and perfectly printable. Image Credit: Sangiorgio, V et al., Sustainability

The Future

The paper published in Sustainability has provided a significant knowledge base for future research in the area of 3D printing sustainable, high-performance components from clay materials. The authors have stated that future research will investigate both the thermal and structural performance of 3D-printed bricks. Additionally, further studies will explore modifying the external brick shell for enhancing the combination of 3D brick printing and automatic robotic wall construction.

Further Reading

Sangiorgio, V et al. (2022) The New Boundaries of 3D-Printed Clay Bricks Design: Printability of Complex Internal Geometries [online] Sustainability 14(2) 598 | mdpi.com. Available at: https://www.mdpi.com/2071-1050/14/2/598

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.