By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Feb 17 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Feb 17 2022In an article recently published in the journal Food Chemistry: Molecular Sciences, researchers presented a strategic approach for the development of an edible coating based on biopolymers to extend the shelf life of horticultural goods.

Study: Biopolymer-based edible coating for enhancing the shelf life of horticulture products. Image Credit: Komsan Loonprom/Shutterstock.com

Background

According to a United Nations estimate, 50% of all fruits and vegetables are lost each year. Coatings are being used by industries to prevent post-harvest losses. The most popular method for preserving fruits and vegetables is wax coating. Sometimes wax is combined with chemical substances that are known to be carcinogenic.

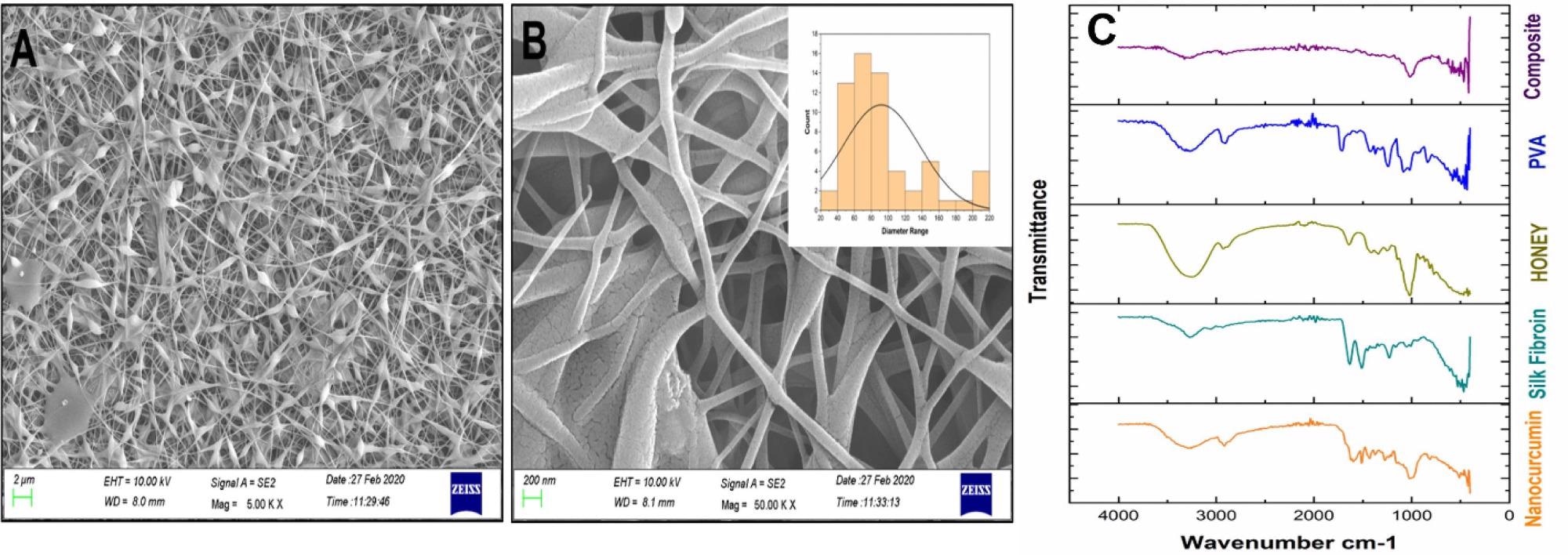

(A) Field emission scanning electron microscopy (FE-SEM) images of Silk fibroin composite nanofibers (SF-honey-nanocurcumin-PVA) (A) 2 µm scale bar (B) 200 nm scale bar and the average size of NFs (91.797 ± 43.51 nm) was calculated by using Image J software (C) FTIR spectra of nanocurcumin, silk fibroin, honey, PVA (powder form) and composite of silk fibroin-nanocurcumin-honey-PVA. Image Credit: Singh, D. P et al., Food Chemistry: Molecular Sciences

To extend the shelf life of food, various edible films have recently been produced using natural polymers. The edible films operate as a barrier between the food and the outside world, preventing direct contact with air gases and bacteria, lowering the rate of respiration, and keeping the food fresh for longer. Because of its biocompatibility, non-toxicity, higher stability, and good mechanical strength, silk fibroin protein can be used as the base biomaterial for the development of suitable edible films.

However, all of the methodologies and materials investigated so far for edible biofilms use chemical preservatives and necessitate cold storage in addition to dip-coating and sophisticated techniques to extend the shelf-life of vegetables and fruits, all of which are difficult to perform and expensive for farmers or local fruit vendors. As a result, cost-effective coating materials must be synthesized, and coating techniques such as dip-coating for local vendors and farmers and electrospinning for food companies must be used.

About the Study

In the present study, the authors reported the generation of a solution for dip-coating and nanofiber coating by utilizing a blend of silk fibroin, polyvinyl alcohol (PVA), honey, and curcumin, which is a cost-effective way for fruit and vegetable merchants. All the edible coating materials were authorized by the Food and Drug Administration (FDA).

Dip-coating (for local farmers) and electrospun nanofibers coating (for industrial application) were used on perishable fruits and vegetables. PVA was used as a supporting polymer for the electrospun coating, and honey and curcumin as the active agents. Honey acted as a natural moisturizer, while curcumin acted as an antibacterial and antioxidant agent. The fruits and vegetables were directly coated with electrospun nanofibers by placing them on the collecting plate, and the dip-coating was done by dipping the vegetables and fruits in silk fibroin solution, which included active agents.

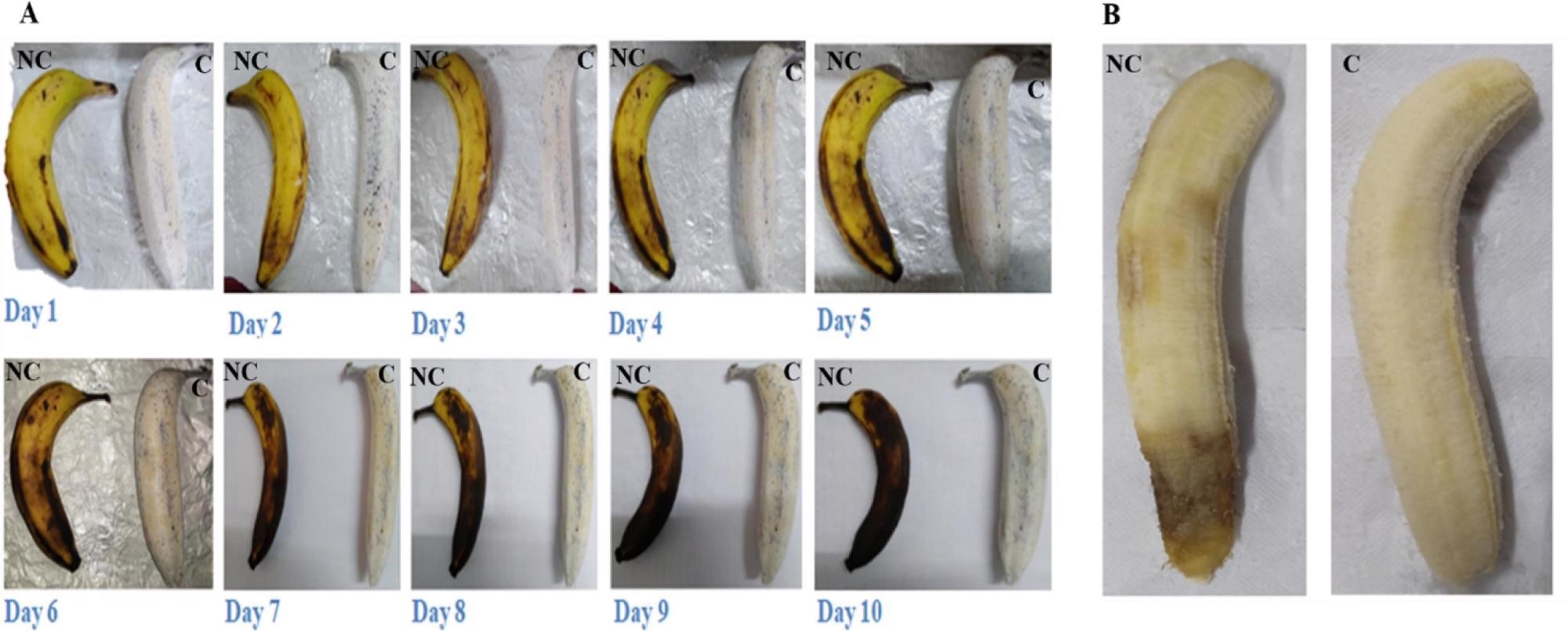

(A) Time-lapse photography of silk fibroin composite nanofiber coated banana (150 min total electrospinning time by changing the position of banana to allow the proper coating from all sides) and uncoated banana. (B) Banana without peel on 6th day; Note: NC– non-coated, C- coated. Image Credit: Singh, D. P et al., Food Chemistry: Molecular Sciences

Silk fibroin-based dip coating and electrospun nanofibers were employed as edible coatings for the preservation of horticulture crops. Ultraviolet (UV)–visible spectroscopy was used to measure optical density for the antibacterial study. Fourier transform infrared spectroscopy (FTIR) analysis was used to verify the presence of curcumin and honey in silk fibroin solution and electrospun nanofibers.

The morphology and average size of the silk fibroin nanofibers (SFNFs) were discovered using field emission scanning electron microscopy (FESEM). The 2,2-diphenyl-1-picrylhydrazyl (DPPH) assay was used to determine curcumin's antioxidant capabilities. Thermogravimetric (TG) analysis was used to investigate the moisturizing capabilities of honey in SF composite nanofibers. The water contact angle was used to confirm the wettability of the nanofibers. External appearance, stiffness, taste, and texture variations in horticultural crops (fruits and vegetables) were studied using time-lapse photography.

Observations

In this study, the researchers observed that the shelf life of coated perishable fruits such as bananas (ripe and unripe), apples (including slices), and oranges (including slices) were successfully extended while the coating also helped maintain the weight, stiffness, and fruit quality. The shelf life was found to be nearly doubled. Incorporating an antioxidant and antibacterial ingredient (nano-curcumin) in SFNFs was described as a one-step, repeatable technique.

Furthermore, it was observed that the fruits and vegetables with a coating had a longer shelf life. The banana which had a coating of edible nanofibers remained eatable for up to eight days, with excellent texture and quality, whereas the uncoated banana remained eatable for just three to four days.

The coated apple remained intact for almost three weeks and lost very little weight compared to the untreated apple. The coated apple remained in fine shape while the untreated apple burst out on the 22nd day and lost its stiffness. Similarly, the zebrafish dip-coating was used as a model and was found to be stable for 48 hours.

Conclusions

In conclusion, this study elucidates the utility of silk cocoons/fibroin that has been discarded by the industry for the development of nano-coatings that are edible and provide additional nutrition. It was also concluded that such a dip coating would be ideal for the exportation of meat and other non-vegetarian meals that degrade quickly during travel. The authors believe that this method of food preservation is cost-effective and may also be utilized as a simple dip-coating that does not require any specific skills, making it ideal for local sellers.

Overall, this work demonstrated that the silk fibroin could be used as an edible covering biomaterial loaded with antioxidants and antimicrobials in electrospun nanofibers. The authors emphasized that silk fibroin is a visually appealing biomaterial that may be used for a variety of biomedical purposes as well as an edible coating material in the field of food nanotechnology.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Singh, D. P., Packirisamy, G., Biopolymer based edible coating for enhancing the shelf life of horticulture products. Food Chemistry: Molecular Sciences 4, 100085 (2022). https://www.sciencedirect.com/science/article/pii/S2666566222000132