By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Feb 21 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Feb 21 2022In an article recently published in the open-access journal Materials, the researchers presented a strategic approach for the non-destructive magnetic investigation of cladded nuclear reactor blocks.

Study: Magnetic Investigation of Cladded Nuclear Reactor Blocks. Image Credit: Parilov/Shutterstock.com

Background

Nuclear power plants (NPPs) are utilized to generate electricity in all major industrial countries today. However, the Fukushima Daiichi disaster halted the nuclear energy renaissance, and safety measures have been improved since then.

Because the mechanical properties of the reactor pressure vessel (RPV) wall are affected during operation, regular examination of nuclear power plants is critical. Magnetic methods are suitable for this inspection since the RPV material is ferromagnetic steel. Also, these methods are useful because they are inexpensive, technically straightforward, and may be used in a wide range of materials.

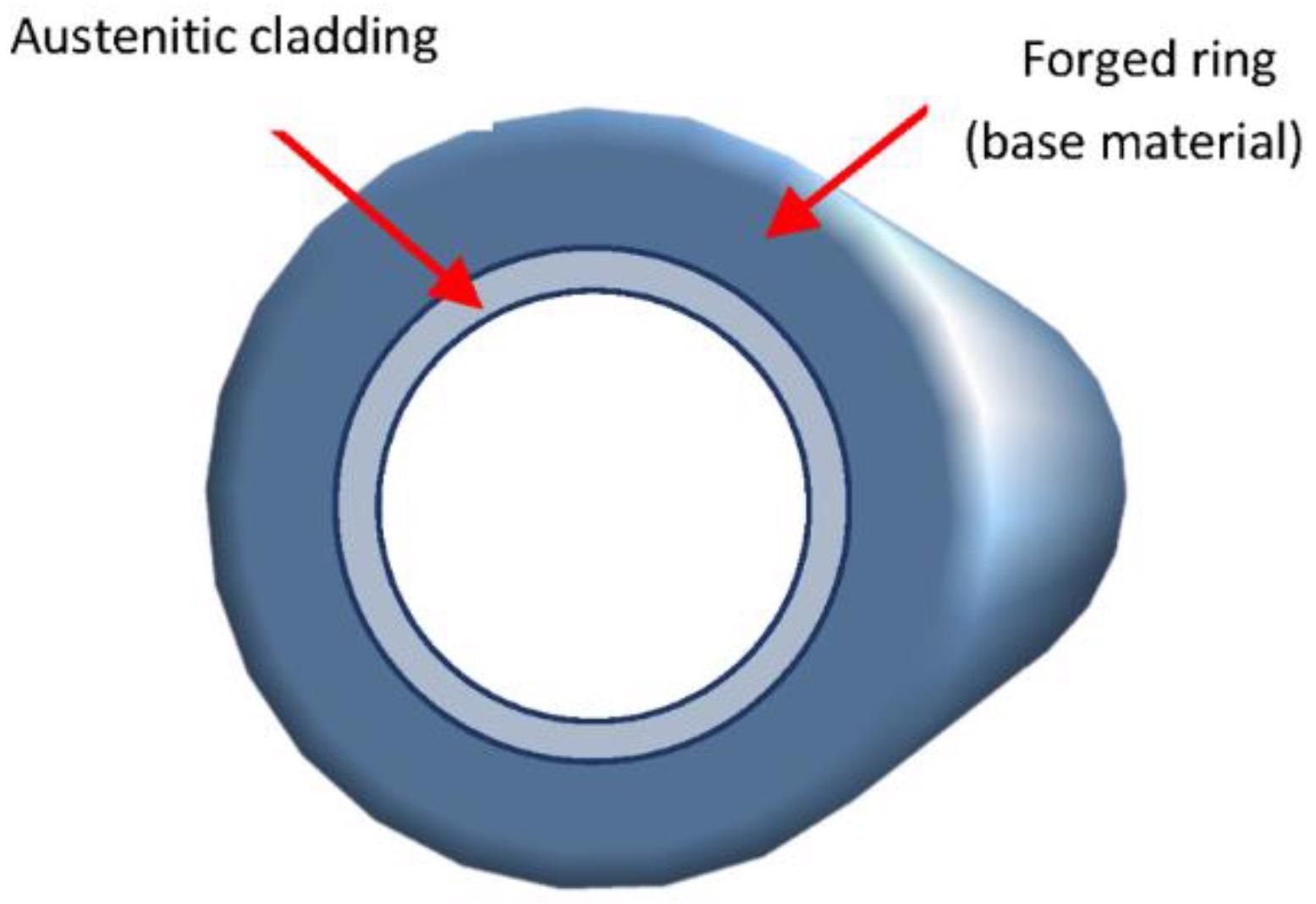

Cutting of the cladded block from a forged ring. Image Credit: Vertesy, G et al., Materials

The implementation of these methodologies resulted in a reasonable correlation between destructively measured parameters and non-destructively measured magnetic properties. This opens the possibility of using magnetic technologies to inspect the structural integrity of RPVs in the future.

A tool for non-destructive evaluation of the embrittlement of the vessel wall should be developed for the future inspection of nuclear reactors. The final system should be able to inspect the microstructure degradation as it passes through the cladding.

About the Study

In the present study, the authors investigated the potential of non-destructive magnetic measurements for the inspection of the base material and the cladding separately. An austenitic (extremely weakly ferromagnetic) coating covered the ferromagnetic steel wall of a nuclear reactor pressure vessel. The cladding material was primarily austenitic; however, it contained a small amount of ferrite (magnetic) phase (2–8%).

The influence of yoke size was investigated using a numerical simulation of magnetic flux injected into the material during magnetic measurements. Measurements were taken using two different sizes of yokes on base material under cladding, pure base material, and on cladding itself. Experiments were conducted to validate the simulation's findings.

The cladded RPV blocks were evaluated after being thermally treated using a step cooling process, which resulted in material embrittlement. Magnetic measurements were used to demonstrate the tracking of the degradation of the underlying material through the cladding.

The right size of the magnetizing yoke was determined as different sizes of yokes could be employed for base metal and cladding characterization. The effect of the yoke dimension was calculated by numerical simulation of the magnetic flux distribution in the sample to produce a qualitative interpretation of the experimental results. The two types of extremely magnetically distinct components (ferromagnetic base metal and virtually austenitic cladding) were studied individually using two magnetizing yokes of different diameters.

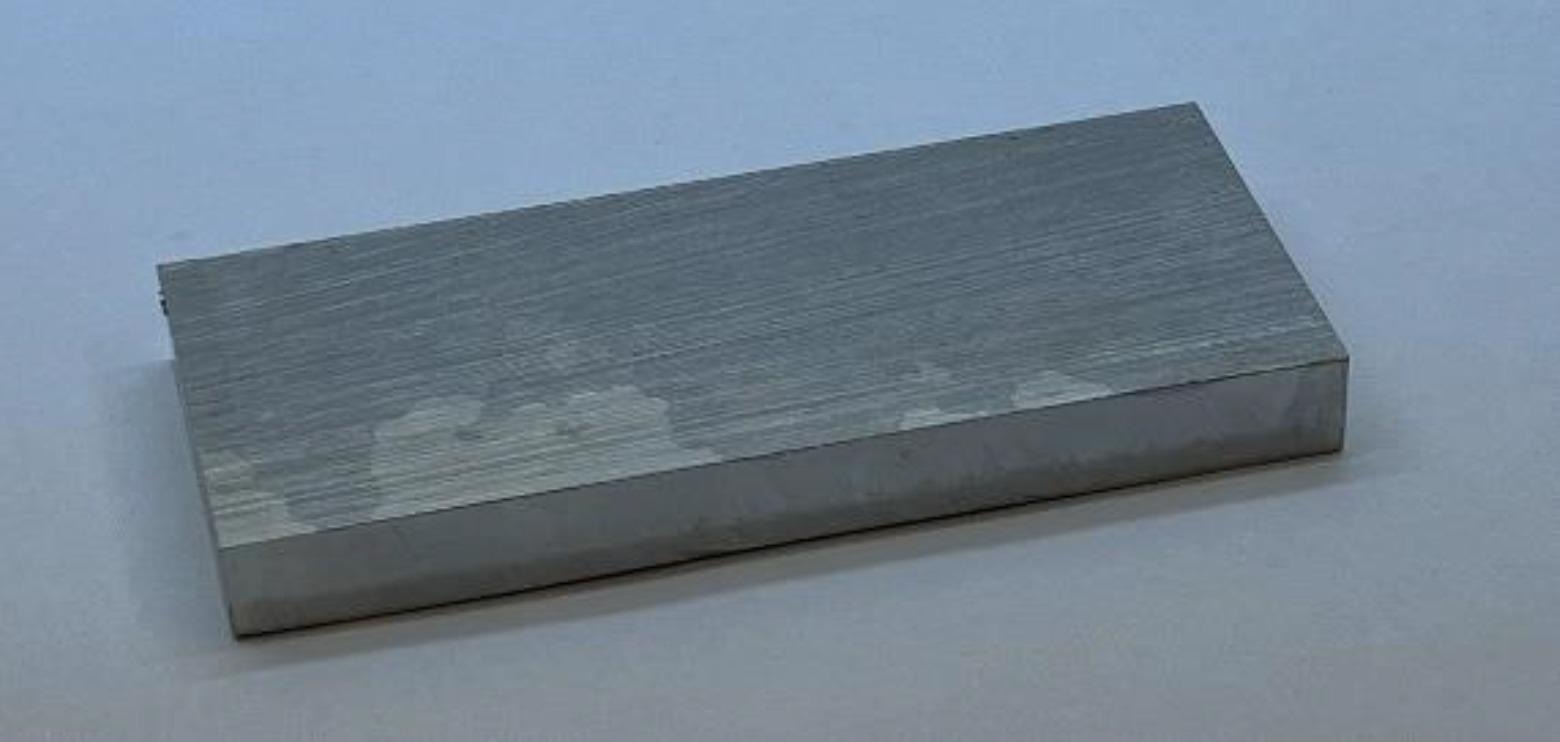

Photograph of the cladding itself (cut from the top of another cladded block). Image Credit: Vertesy, G et al., Materials

Observations

The researchers observed that by selecting the right magnetizing yoke, the base material and cladding could be measured separately from one another. Furthermore, it was shown that the magnetic characteristics and the ductile to brittle transition temperature had a stable, almost linear relationship.

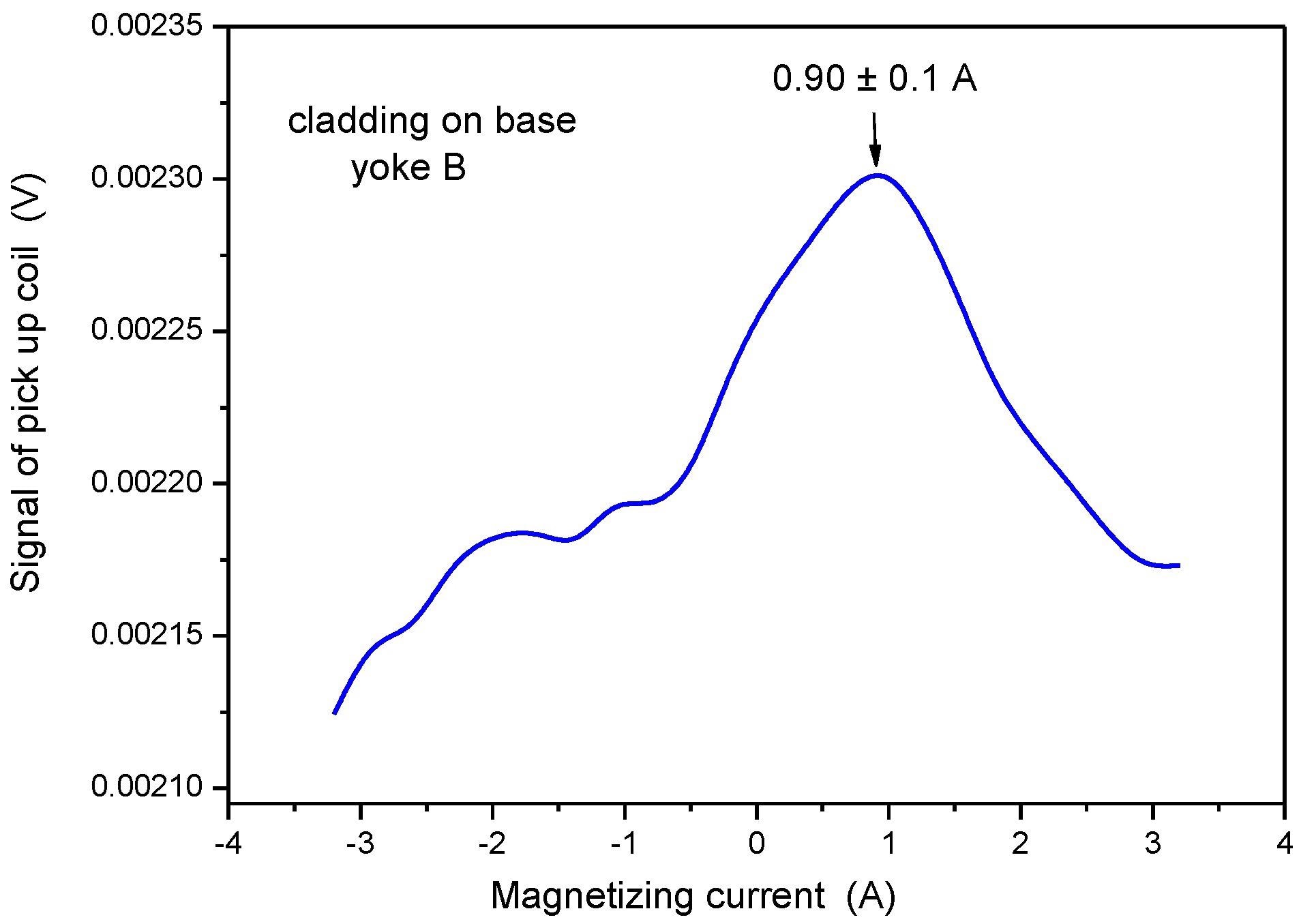

This research investigated whether magnetic measurements might be used to investigate the base material and cladding separately. It was observed that the ferromagnetic base metal could be measured with the use of a big yoke. Since the signal from the ferromagnetic component suppressed the signal corresponding to the weakly magnetic cladding, this yoke was not found suitable for investigating cladding on top of the base material. In the existence of highly ferromagnetic steel, the cladding itself was measured with the use of a tiny yoke.

The magnetic flux was contained within the cladding and was unable to pass through to the base material. Based on the simulation of the distribution of the magnetic flux in the given geometry, the influence of different yoke dimensions was established.

The measurement results were found to be well in agreement with the modeling studies. The findings also demonstrated the viability of a simple and non-destructive magnetic method to check the prospective material degradation of austenitic cladding over the pressure vessel due to various influences such as neutron irradiation, heat treatment, and so on.

Signal of the pick-up coil as a function of the magnetizing current, measured on the top of the cladded block by applying Yoke B. Image Credit: Vertesy, G et al., Materials

Conclusions

In conclusion, this study elucidates a non-destructive approach for characterizing the cladded blocks of a nuclear pressure vessel using magnetic technology. It was also concluded that this method of research holds the potential to monitor the integrity of the reactor's multiple layers. The authors believe that the current findings may aid in the future practical implementation of magnetic technologies in nuclear power plant inspections.

Overall, this work demonstrated that this method of testing a bilayer material with two distinct yoke sizes can be used in other situations where a weakly ferromagnetic layer is placed on highly ferromagnetic material.

This would make the effort more significant than if it were only related to the testing of one wall. The authors emphasized that the material degradation of cladding caused by any event such as thermal shock, neutron irradiation, elastic or plastic deformation could be investigated in the future using magnetic hysteresis measurements, primarily magnetic adaptive testing.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Vertesy, G., Gasparics, A., Szenthe, I., et al. Magnetic Investigation of Cladded Nuclear Reactor Blocks. Materials 15(4), 1425 (2022). https://www.mdpi.com/1996-1944/15/4/1425