Researchers from Portugal have reported the eco-friendly synthesis of bacterial cellulose films, a functional bioactive material that has potential applications in fields including biomedicine. Their findings have been published online in the journal Materials.

Study: Characterization of Bioactive Colored Materials Produced from Bacterial Cellulose and Bacterial Pigments. Image Credit: NatalieIme/Shutterstock.com

Bacterial Cellulose

Bacterial cellulose is a biomaterial produced by microorganisms, which possesses remarkable properties such as high mechanical strength. This attractive physical property is due to the material’s web-like network structure, high degree of polymerization, superior capacity for holding water, porosity, and high crystallinity. Bacterial cellulose also possesses bioactive properties such as antioxidant and antibacterial activity, as well as biodegradability and non-toxicity.

![CIE Chromaticity diagram obtained using GOCIE software [42], from the sample’s spectra provided by Datacolor 110 spectrophotometer. The diagram allows the perception of the samples color from the distributions of wavelengths in the electromagnetic visible spectrum.](https://www.azom.com/images/news/ImageForNews_58514_16472515245397273.jpg)

CIE Chromaticity diagram obtained using GOCIE software, from the sample’s spectra provided by Datacolor 110 spectrophotometer. The diagram allows the perception of the samples color from the distributions of wavelengths in the electromagnetic visible spectrum. Image Credit: Amorim, L et al., Materials

Applications of bacterial cellulose proposed and explored in recent years include cosmetics, biomedicine, electronics, paper additives, food packaging, food substitutes, food additives, and filtration membranes. The bioactive properties of bacterial cellulose are advantageous for many applications, such as preventing bacterial colonization when it is used as a wound dressing by helping to accelerate the healing process.

Moreover, commonly used antioxidant agents such as metallic nanoparticles have limited applicability due to their potential toxicity and chemical synthesis methods. Synthetic phenolic antioxidants also have undesirable properties such as potential carcinogenicity, high volatility, and instability at elevated temperatures. Using natural, non-toxic, and bioactive alternatives overcomes these issues.

Bacterial Pigments

Pigments derived from microorganisms possess properties that make them an attractive alternative to conventional, synthetic compounds currently used in several industries. Microbial pigments can be produced in large quantities in a short period of time without the need for harsh chemical reagents and are sustainable, biodegradable, and environmentally friendly. Recently, the production of bacterial pigments using fermentation has increased, achieving high yields of these compounds.

An advantage of bacterial pigments over plant-derived alternatives is their season independence, facilitating year-round production. The production of these compounds can be highly tailored by optimizing the process parameters of production methods such as solid-state or submerged fermentation. Process parameters include pH, temperature, aeration, and carbon source. Moreover, the handling of these materials is safer due to their non-toxicity and lack of carcinogenicity.

Many properties of pigments have been widely reported in studies which make them suitable for application in diverse research fields. Prodigiosin, a red bacterial pigment, possesses anticancer, antimalarial, antifungal, immunosuppressive, and UV protective properties. Studies have reported its production by numerous microorganisms such as Streptomyces longisporus ruber, Serratia marcescens, Pseudomonas magneslorubra, and S. plymuthica.

Furthermore, the yellow flexirubin-type pigment displays a large range of pharmacological effects such as superior antioxidant activity and has been used in the treatment of gastric ulcers, eczema, and chronic skin diseases. Flexirubin was initially isolated from Flexibacter elegans. Several genera produce modified flexirubin pigments.

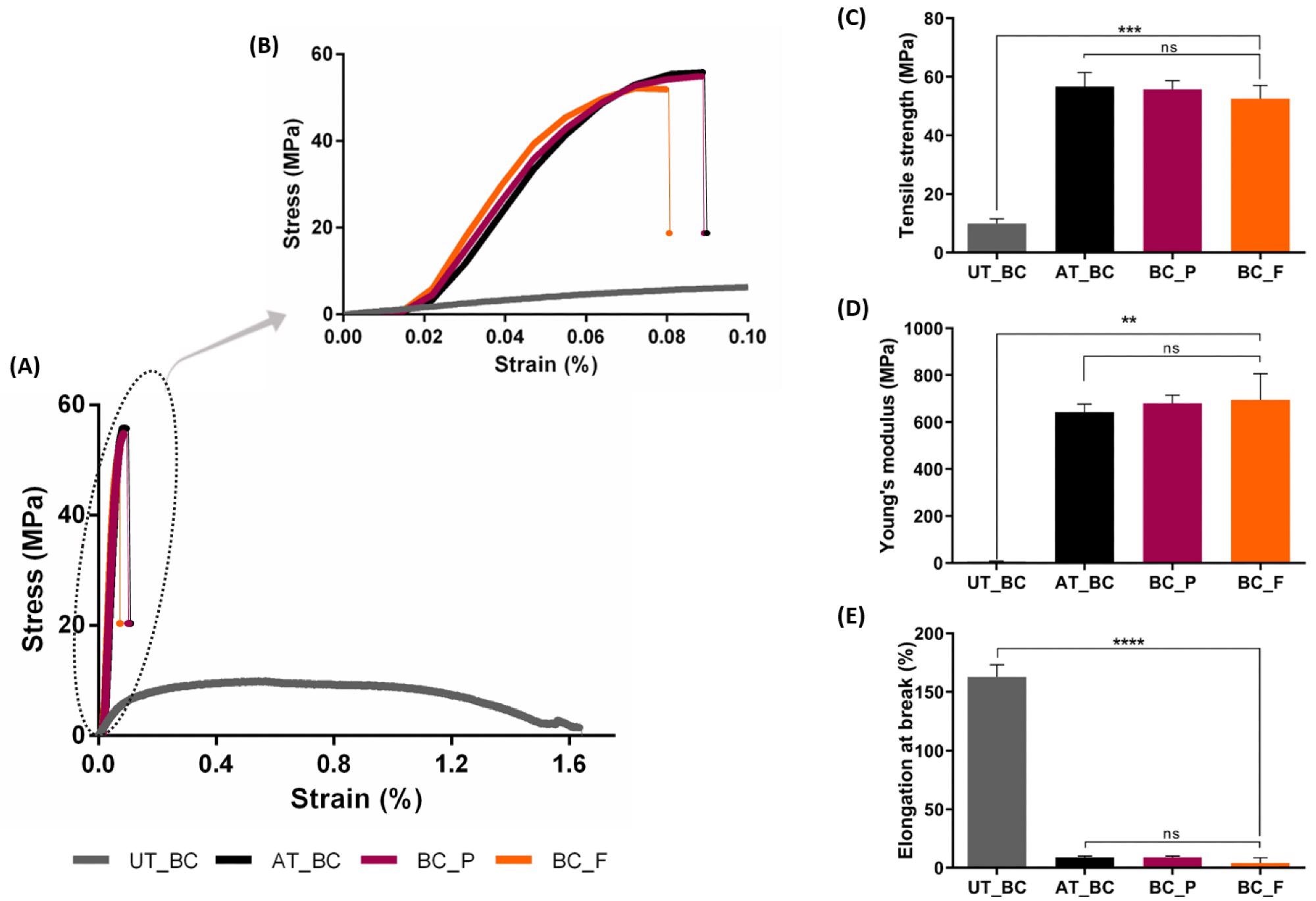

Summary of mechanical performance of untreated BC (UT_BC), alkaline-treated BC (AT_BC), BC functionalized with prodigiosin (BC_P), and BC functionalized with flexirubin-type pigment (BC_F): (A) tensile stress-strain curves; (B) close-up view of tensile stress-strain curves of AT_BC, BC_P, and BC_F; (C) tensile strength, (D) Young’s modulus, and (E) elongation at break of BC samples. (Data are presented as mean ± SD, ns indicates non-significant, ** p < 0.01, *** p < 0.001, and **** p < 0.0001). Image Credit: Amorim, L et al., Materials

The Study

In the study, the authors have reported the production of bacterial cellulose films functionalized with pigments, which imbue the films with enhanced bioactivity. Recent studies have been carried out into colored bacterial cellulose fabrics using acid and synthetic dyes, as well as using natural plant-based dyes including anthocyanin for use in colorimetric pH indicators, using immobilized enzymes, and using fungal pigments to produce functional foods.

The authors have stated that, to their knowledge, no reports of using bacterial pigments to functionalize bacterial cellulose and obtain bioactive and colored materials. The authors isolated red prodigiosin from S. plymuthica and yellow flexirubin-type pigment from Chryseobacterium shigense isolated from a beverage of lactic acid. An advantage of adding bioactivity to bacterial cellulose using pigments is the color provided, which produces value-added products without the need for undesirable finishing steps.

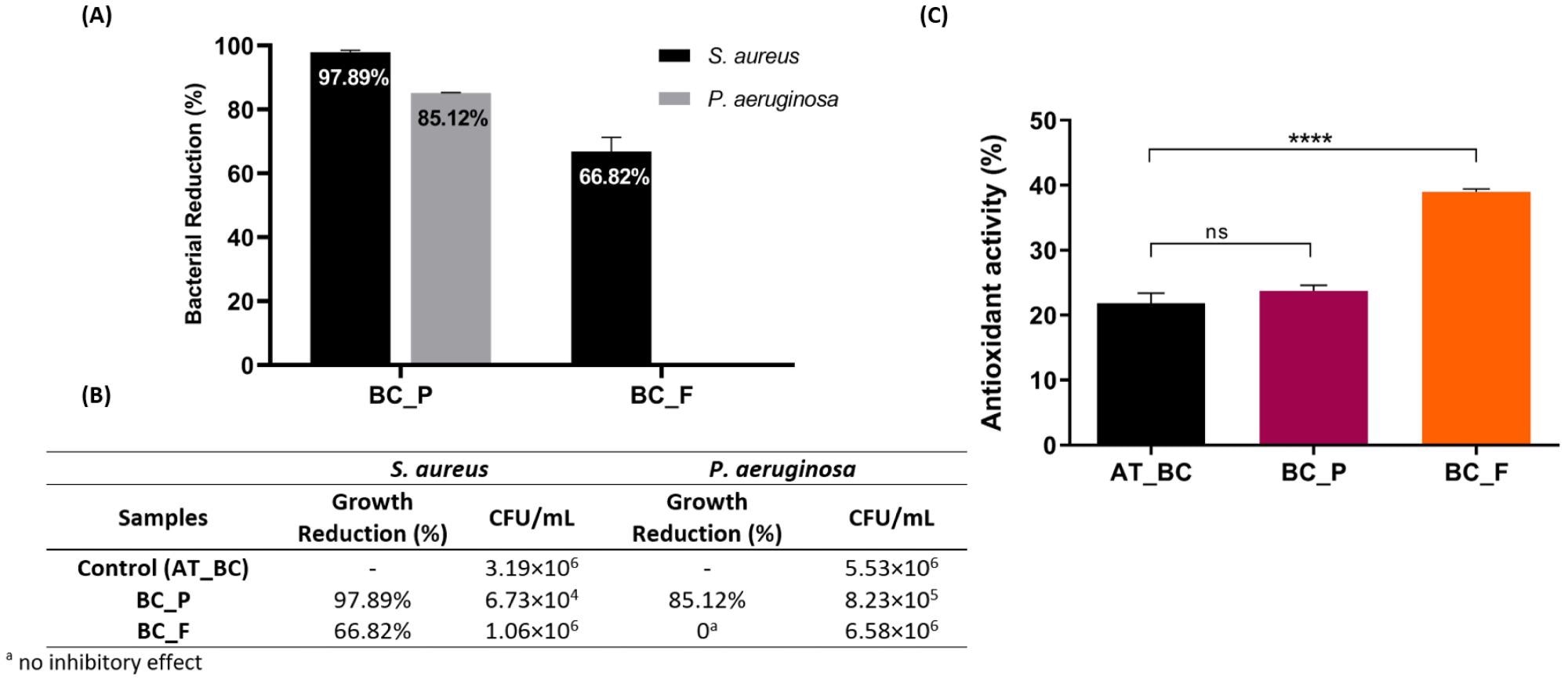

Antibacterial and antioxidant activity evaluation: (A) growth inhibition by BC functionalized samples, with prodigiosin (BC_P) and flexirubin-type pigment (BC_F), against pathogenic bacteria S. aureus and P. aeruginosa; (B) correspondence between the percentage of bacterial reduction and the respective CFU/mL; (C) percentage of radical ABTS scavenging activity of BC samples (alkaline-treated BC, AT_BC, BC after functionalization with prodigiosin, BC_P, and BC after functionalization with flexirubin-type pigment BC_F). (Data are presented as mean ± SD, ns indicates non-significant, and **** p < 0.0001). Image Credit: Amorim, L et al., Materials

Bacterial cellulose was functionalized at a temperature of 40oC over the weight of the fiber for 60 minutes. The functionalized material’s mechanical properties, hydrophilicity, and porosity were analyzed and categorized. Moreover, its bioactivity, namely anti-pathogenic and free radical scavenging activity, was evaluated to investigate its potential applications in a variety of fields. Color characteristics were investigated, and the material’s water contact angle was measured.

Renewable sources of materials were used to facilitate a sustainable synthesis method. No chemical mordants and finishing agents were used. The bacterial pigment functionalized bacterial cellulose films were able to successfully inhibit common pathogenic bacteria such as P. aeruginosa and S. aureus. Prodigiosin played a role in the inhibition activity, with the flexirubin-type pigment facilitating the scavenging of free radicals.

Furthermore, the mechanical performance, porosity, and hydrophilicity of the bacterial cellulose films was retained after incorporation. The superior bioactivity and mechanical performance of the novel material makes it an attractive candidate for applications where these properties are required, such as medical devices, food packaging, and textiles.

Finally, the authors have proposed that this bacterial pigment-functionalized bacterial cellulose film can be used in the development of intelligent wound dressings that change color in the presence of alkaline pH, which is an indicator of wound infection.

Further Reading

Amorim, L.F.A, Fangueiro, R & Gouveia, I (2022) Characterization of Bioactive Colored Materials Produced from Bacterial Cellulose and Bacterial Pigments [online] Materials 15(6) 2069 | mdpi.com. Available at: https://www.mdpi.com/1996-1944/15/6/2069

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.