Scientists have reviewed current progress in the synthesis of bacterial cellulose-based nanocomposites and their potential applications. Their findings have been published in the journal Polymers.

Study: Bacterial Cellulose-Based Polymer Nanocomposites: A Review. Image Credit: Kallayanee Naloka/Shutterstock.com

Bacterial Cellulose

There are several different forms of cellulose that can be used for commercial applications, including cellulose nanocrystals, cellulose nanofibers, microcrystalline cellulose, and bacterial cellulose. Bacterial cellulose is also referred to as bacterial nanocellulose. Easy functionalization of the -OH bonds in these different forms of cellulose gives them their wide applicability in a number of important industrial fields.

Despite their similar composition, bacterial cellulose and plant cellulose differ in their fundamental properties and structure. The main difference is that bacterial cellulose is of higher purity, without the presence of lignin, pectin, and hemicellulose. Due to its purity, the downstream processing costs of bacterial cellulose are far lower than that of plant-derived cellulose.

Another key benefit of bacterial cellulose is its enhanced surface area compared to plant cellulose (up to two hundred times greater.) Additionally, the strictly parallel structure of bacterial cellulose imparts high degrees of crystallinity, polymerization, and enhanced tensile strength. Furthermore, bacterial cellulose is non-toxic and non-polluting. Moreover, bacterial cellulose possesses good water retention behavior.

Bacterial cellulose synthesis is extremely efficient due to the short growth cycle, rapid metabolism, and high reproduction rates of microorganisms. This also improves the cost-efficiency of cellulose synthesis from bacterial species compared to plant sources. Furthermore, bacterial cellulose can be modified and possesses good formability, widening the commercial application potential for this biopolymer.

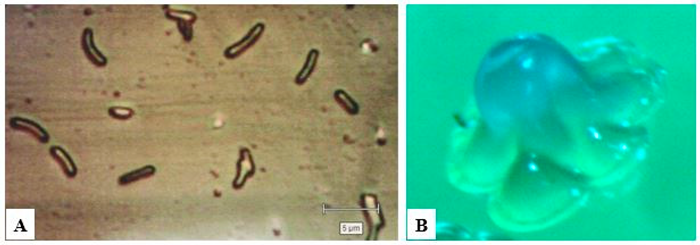

Cell morphology (A) (×1500) and colonies (B) (×100) K. sucrofermentans H-110. Image Credit: Revin, V.V et al., Polymers

The Study

Several perspectives, recent advances, and applications, primarily in the biomedical and environmental fields, have been reviewed by the authors. The paper is an updated assessment of the state-of-the-art in this research field.

Another key contribution of the review paper is the discussion of progress in combining bacterial nanocellulose with other polymers and biologically active agents such as drugs, inorganic substances, and metals. Producing composites of bacterial nanocellulose and these compounds is helping to develop novel composites which have a wide array of applications in the biotechnology and biomedical sectors.

Sustainable and Efficient Bacterial Nanocellulose Production Methods

Bacterial cellulose is produced by several Gram-negative and Gram-positive bacterial species. Whilst this biopolymer possesses high potential for multiple important applications, large-scale production of bacterial cellulose is currently challenging. There is an urgent need for an efficient, replicable, and cost-effective production process.

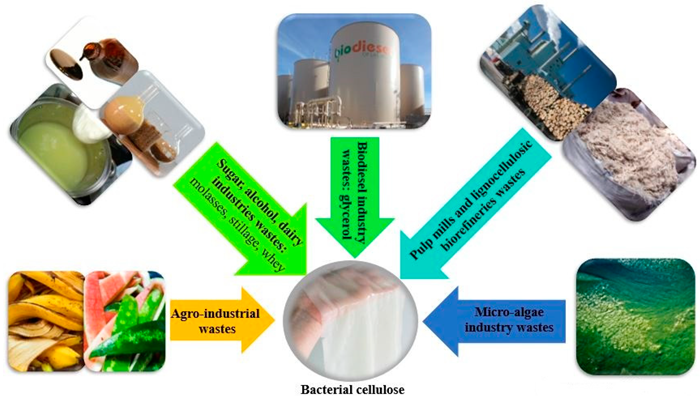

Cell-free culture methods have emerged as highly promising strategies for the industrial-scale synthesis of bacterial cellulose. Additionally, cost is a key limitation in bacterial cellulose synthesis, which has focused the attention of researchers on utilizing industrial, food, and agricultural waste products as cost-effective substrates. Several studies have demonstrated the development of high-purity bacterial nanocellulose from waste products.

Schematic overview of bacterial cellulose production from different industrial wastes. Image Credit: Revin, V.V et al., Polymers

Bacterial Cellulose Nanocomposites

Whilst bacterial nanocellulose possesses several benefits, such as biodegradability, biocompatibility, high mechanical strength, high crystallinity, and high surface area, there are some properties it lacks. These include antimicrobial activity, catalytic activity, electromagnetic properties, and antioxidant properties, which are required for specific applications.

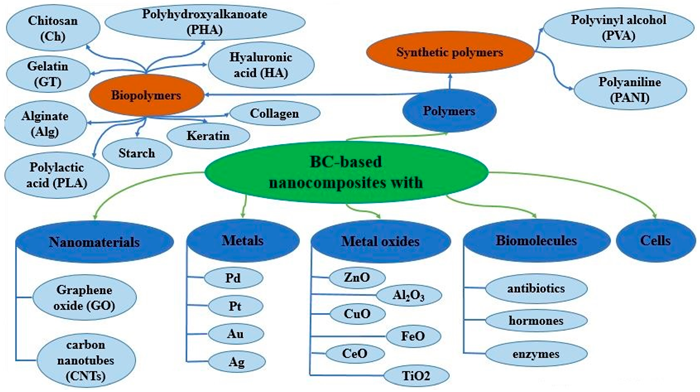

To impart bacterial nanocellulose with these functional properties, researchers have produced several modified bacterial nanocellulose composites in recent years. Bacterial cellulose can be functionalized via several chemical and physical methods. Composites have been produced which incorporate polymers, nanoparticles, clays, carbon-based nanomaterials, and metal oxides.

Key methods have been developed by scientists to introduce components into bacterial nanocellulose matrixes to produce composites. These include chemical modification after processing and purification and genetic manipulation of microbial organisms. In-situ and ex-situ approaches have been explored in recent research to produce high-strength, biocompatible, and functionalized composites.

Applications

Recent research has produced many promising bacterial nanocellulose-based biocomposites for applications in the environmental, biomedical, and biotechnological fields. Currently, many reported materials suffer from low mechanical properties and poor antibacterial activity, and improving these properties is a key focus of current research.

Applications in the biomedical industry include wound dressings, cancer treatment, drug delivery, soft tissue engineering, and bone tissue engineering. Reinforcement materials such ZnO nanoparticles, reduced graphene oxide, PVA, and montmorillonite have imparted nanocomposites with favorable properties such as enhanced thermal stability, biocompatibility, hemostasis, and anisotropy.

Additionally, functionalized bacterial cellulose composites have been successfully applied in biosensors and as adsorbents for wastewater treatment to remove organic and inorganic pollutants.

A generalized classification of BC composites prepared with various materials of organic and inorganic nature. Image Credit: Revin, V.V et al., Polymers

Conclusions and Future Outlook

Whilst some key challenges remain, the potential for bacterial cellulose-based materials to provide innovative solutions for pressing medical and environmental needs is high. The review paper has provided a comprehensive analysis of the current progress in developing these industrially important, sustainable biomaterials.

The authors have noted that there are some key research directions that should be explored more in-depth in future studies, such as utilizing waste materials to improve the cost-effectiveness and yield of nanocomposite synthesis. Metabolic and genetic engineering as well as optimizing low-cost culture media, cell-free culture methods, and equipment.

Finally, novel modification and functionalization processes could greatly benefit the production of new and innovative bacterial cellulose composites. This will provide new opportunities for developing materials that can improve quality of life and overcome key environmental and medical issues which face humanity in the 21st century.

Further Reading

Revin, V.V et al. (2022) Bacterial Cellulose-Based Polymer Nanocomposites: A Review Polymers 14(21) 4670 [online] mdpi.com. Available at: https://www.mdpi.com/2073-4360/14/21/4670/htm

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.