A recent study published online in the journal ACS Polymers at the end of last year has investigated the effects of solvent properties on the elasticity of electrospun polymers. The research has implications for the design of materials for use in fields such as wearable electronics and medical research.

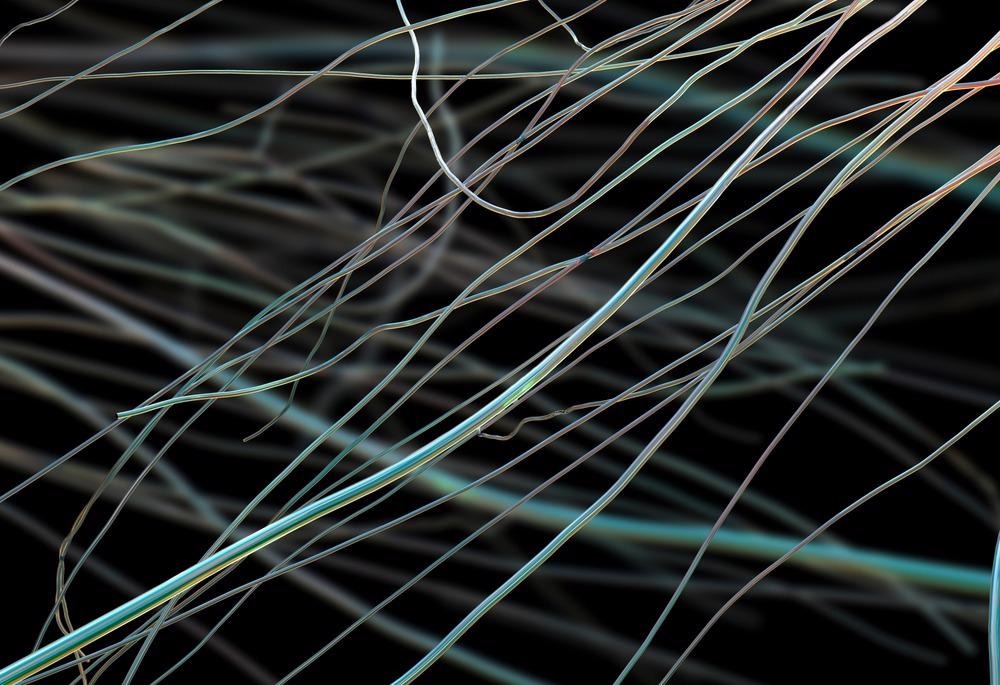

Study: Solvent Effects on the Elasticity of Electrospinnable Polymer Solutions. Image Credit: Kateryna Kon/Shutterstock.com

Ultrafine Fibers

Ultrafine fibers have been a recent research focus in the textiles industry and materials science. Studies have been carried out into investigating the use of these fibers in both conventional textiles and for smart textile applications in wearable electronics, sensors, and devices used for bioengineering. Ultrafine fibers are defined as fibers with dimensions of less than 5 μm.

However, their current commercial applications are limited to filtration devices and biomedical scaffolds, with a lack of research into their use in advanced applications for consumer products and microelectronics. Research into the use of ultrafine fibers for these fields will increase the number of materials that can be utilized, such as polymers and additives, and will require a greater range of solvents used during spinning processes as dopes. This will affect the fiber formation processes.

Challenges with Ultrafine Fiber Spinning Processes

Large-scale spinning processes used in fiber formation, such as melt spinning, wet spinning, and dry spinning, are affected by large changes in fluid flow properties. However, spinning processes for ultrafine fibers such as electrospinning face unique challenges during fiber formation. These processes can be significantly affected by small changes in properties such as elasticity, surface tension, conductivity, and viscosity.

Due to these challenges, there is an urgent need for research to investigate the relationship between the chemical composition of materials to multicomponent mixture processing. Elucidating this knowledge will aid the development of ultrafine fiber-based smart materials for use in emerging technologies.

Electrospinning is widely regarded as the forerunner amongst manufacturing technologies for producing ultrafine fibers. In this process, the pulling force is provided by electrical fields instead of applying mechanical force. However, this process suffers from high cost and low productivity, which limits its current use to high-value products such as cell growth scaffolds and pharmaceutical products. Manufacturing these products comes with complex product specifications and high-performance demands.

Bringing electrospun products to market requires a fundamental understanding of how electrospinning is affected by solution properties. Significant knowledge gaps on how viscoelastic behavior is affected by material properties under similar conditions to those experienced during the electrospinning process. Chief amongst these is the elongational flow and fluid extension, which exist at high levels in the process. Currently, it is thought that viscoelasticity and surface tension primarily determine the electrospinnability of polymer solutions.

The Study

The authors have investigated the influence of solvent surface tension on fiber formation. Dripping-onto-solvent (DoS) extensional rheology has been used in the study to investigate the effect of solvent surface tension on the formation of electrospun ultrafine polymer fibers.

More from AZoM: The Circular Economy in the Chemical Sector

Current studies have focused on analyzing shear viscosity to understand the chain entanglement effects and intermolecular attractions in order to deduce the effect on electrospinnability of viscoelastic effects. Especially, they have employed analyses of zero-shear viscosity. The use of extensional rheology is more effective for predicting this as polymer solutions undergo significant elongation and extensional flow during electrospinning.

Additionally, previous studies have not considered low-surface tension solvents or analyzed systems that include multiple polymers and solvents. The authors have stated that this is understandable, as techniques such as capillary breakup extensional rheometry cannot study weakly elastic or low-viscosity solvents due to their lack of sensitivity. DoS extensional rheology deduces that for smooth fiber formation, significantly higher elasticity is required by high-surface tension solutions.

Different polymer/solvent systems were studied by the authors, with both high and low molecular weights. Amongst the results obtained from their analyses, the authors noted that the extensional relaxation time increased in line with polymer concentration, and that increased surface tension requires higher polymer concentrations and, thus, elasticity, to overcome Rayleigh instabilities which drive droplet and bead formations to ensure smooth fiber formation. Increased extensional velocities can further enhance the jet’s stability.

The authors have noted that one solvent property that they did not study in detail was vapor pressure. This was because, in the steady jet region which occurs just past the Taylor cone, solvent evaporation is negligible. They have deduced that it is not likely that solvent evaporation causes any significant difference in fiber formation and thus, vapor pressure is outside the scope of their study.

The authors have stated that by understanding the relationship between solvent characteristics, viscoelasticity, and electrospinnability, the manufacture and design of more complex spinnable solutions will be improved for use in applications such as pharmaceuticals, bioengineering, and wearable electronics. Although the authors have noted that there are some limitations, their study enhances the current knowledge base.

Further Reading

Ewaldz, E, Randrup, J & Brettmann, B (2021) Solvent Effects on the Elasticity of Electrospinnable Polymer Solutions [online] ACS Polym. Au | pubs.acs.org. Available at: https://pubs.acs.org/doi/10.1021/acspolymersau.1c00041

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.