By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Mar 24 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Mar 24 2022In an article recently published in the journal Materials, researchers discussed the development and characteristics of composite films made of pea starch and ε-polylysine.

Study: Preparation and Properties of Pea Starch/ε-Polylysine Composite Films. Image Credit: Sea Wave/Shutterstock.com

Background

Natural polymers such as polysaccharides, lipids, and proteins, which are often used as the substrate for edible packages/films and food coating/packaging, align with the strategy of green development and life/health maintenance. Adding different ingredients to an edible film's recipe can improve its elasticity, processability, and flexibility. The characteristics of starch mixed with other substrates can be designed in several directions to give a theoretical foundation for intelligent applications.

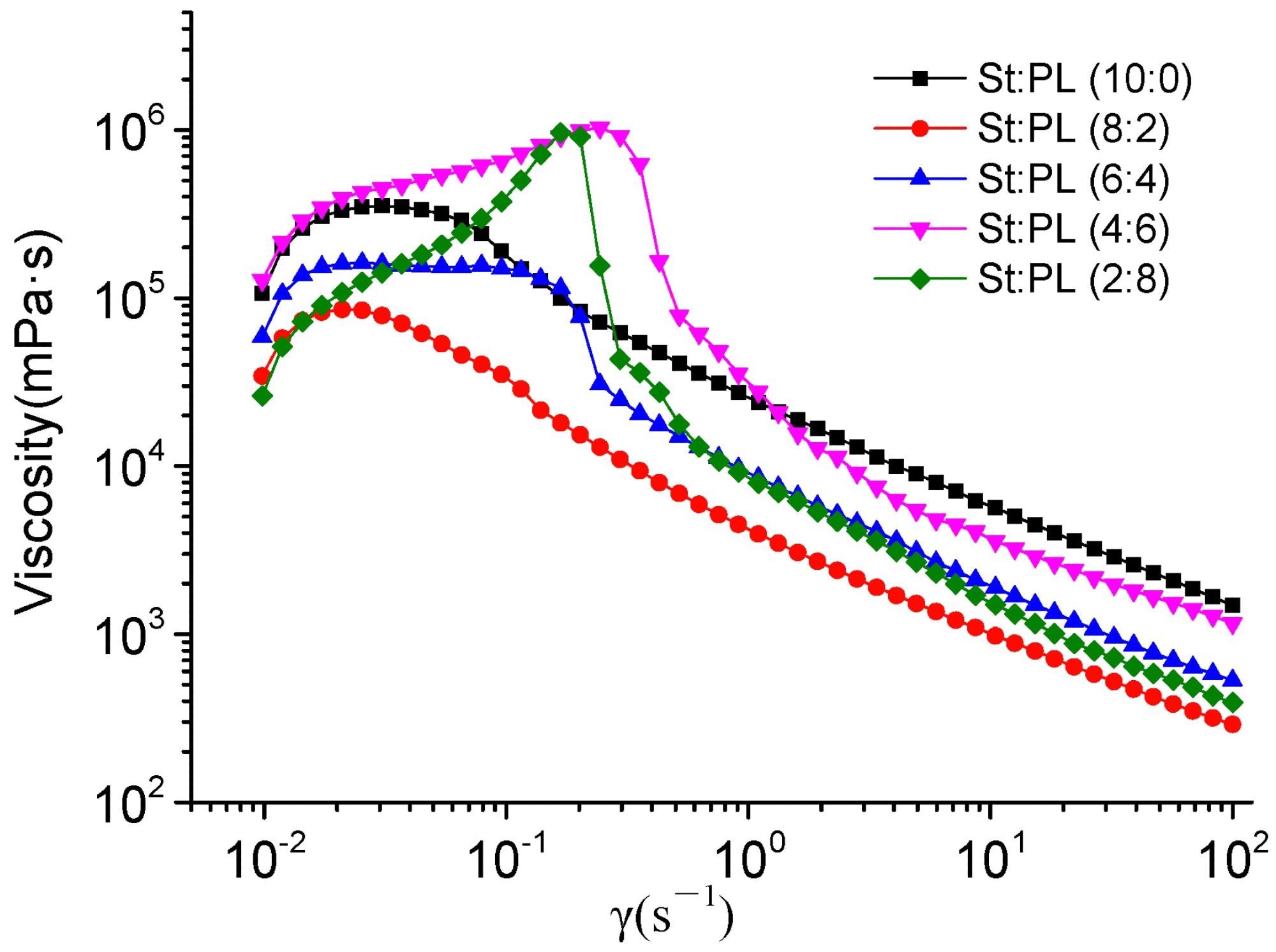

Rheological curves of the film solutions with different St/PL mass ratios. Image Credit: Yu, Z et al., Materials

ε-Polylysine (PL) is frequently used in food anticorrosion, weight loss health care, and medication carriers. Combining PL with γ-polyglutamic acid to produce envelope material can effectively safeguard probiotics' normal physiological functions. Furthermore, coating ready-to-eat goods with PL and natural extracts can successfully extend their shelf life. Also, varying amounts of PL can effectively suppress microbiological growth when added to the starch film.

About the Study

In this study, the authors examined the composite films made of ε-polylysine (PL) and pea starch (St), where St and PL were utilized as the matrix and sodium alginate and glycerol were used as the plasticizers. The composite films' mechanical, rheological, spectroscopic, water vapor permeability (WVP) and oil permeability, thermogravimetry (TGA), microstructure, and antibacterial characteristics were investigated. The proposed five solutions of the film were made up of various pseudoplastic fluids.

The team explored the effects of blends with various proportions of St and PL on film-forming ability and microbial inhibition were explored. The apparent viscosity shear rate curves of the five composite film solutions were measured by using a rheometer. The average value of five points on a film measured with a micrometer caliper was used to calculate the thickness of each composite film. A physical property tester was used to determine the films' tensile strength (TS) and fracture elongation (E).

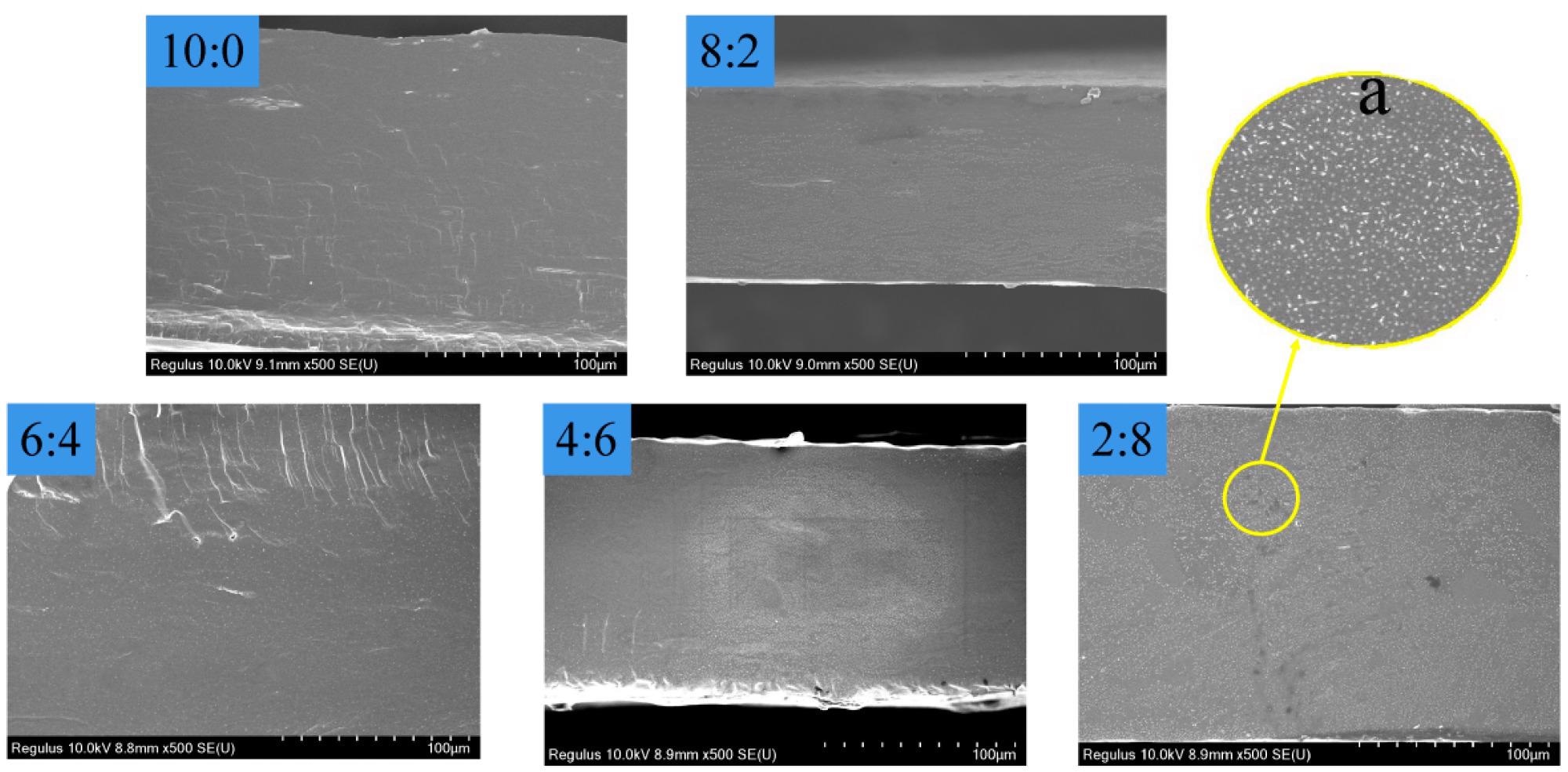

The researchers used the quasi-cup method to determine the WVP of the composite films. The thermal stability of the powder samples was investigated with a thermal analyzer employing TGA and differential thermogravimetric analysis (DTG). A scanning electron microscope was used to examine the morphology of the composite films. To investigate the antibacterial characteristics of the composite films, Escherichia coli (ATCC 25312), yeast (Saccharomyces cerevisiae, ATCC 204508), and Bacillus subtilis (ATCC 23857) were used.

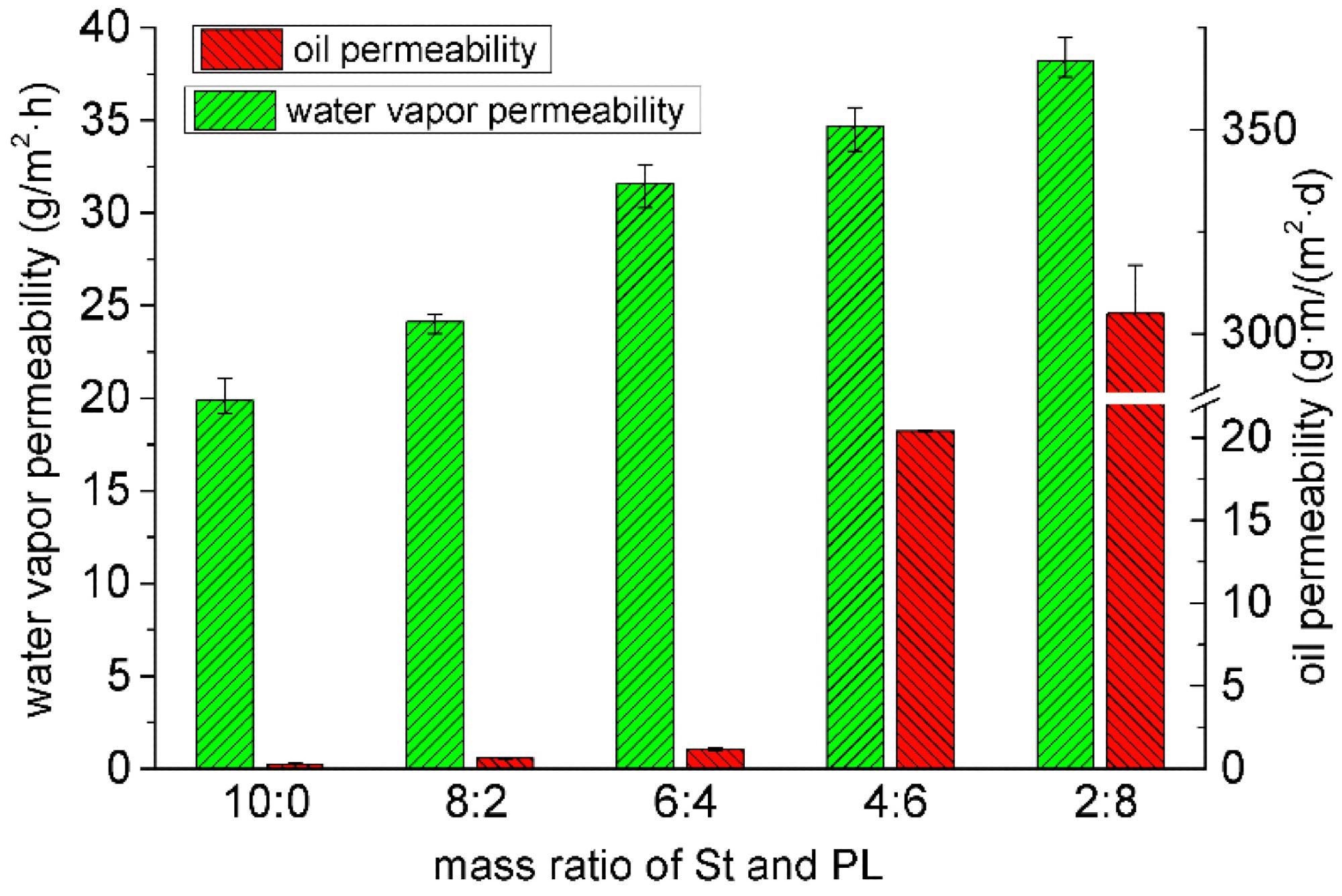

Water vapor permeability and oil permeability of the composite films with St/PL mass ratios. Image Credit: Yu, Z et al., Materials

Observations

The fracture elongation increased from 38.41% to 174.03%, the tensile strength of the blends declined from 9.49 to 0.14 MPa, and the oil resistance and the WVP increased significantly as the mass ratio of PL was increased. The films with wide values of St/PL ratios were quite soluble; however, the film having a St/PL ratio of 2:8 had a lower solubility. The films' inhibition of E. coli, yeast, and B. subtilis increased with higher mass ratios of PL, wherein B. subtilis showed the highest inhibition.

The sample with a St/PL ratio of 4:6 had the maximum viscosity of 1.03 x 106 MPa.s. The film with a 4:6 ratio had a shear rate of 0.241 s-1. The TS declined dramatically when the St/PL mass ratio was altered from 10:0 to 6:4; however, the decline was reduced from 6:4 to 2:8. The break elongation value increased from 38.41 to 172.03% after PL increased the sliding between starch macromolecules. The absorption peaks of PL were 3382, 3362, 3081, 1633, and 1535 cm-1, respectively.

St, on the other hand, had absorption peaks at 3360, 2928, 1646, and 1021 cm-1. Excessive PL hampered the mixing of various substances when the mass ratio of St/PL was 2:8. On B. subtilis, PL had a stronger inhibitory impact than E. coli and yeast. The composite film did not inhibit E. coli or yeast when the PL concentration reached 20%.

The SEM images of the composite films with different mass St/PL ratios. (a) Magnification ×10. Image Credit: Yu, Z et al., Materials

Conclusions

In conclusion, this study elucidated that the characteristics of five St/PL blends made by casting were different. The permeability of water vapor and oil increased in a regular manner. The oil permeability of the composite film had no barrier ability only when the mass ratio of St/PL was 2:8. Moreover, the films inhibited E. coli, B. subtilis and yeast in distinct ways.

St and PL were found to be miscible in a particular percentage. The authors emphasized that they can be considerably reduced following the creation of the starch hybrid film due to the antibacterial capabilities of PL. They also believe that the findings of this study will serve as a database for the application of functional packaging films.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Yu, Z., Gong, D., Han, C., Preparation and Properties of Pea Starch/ε-Polylysine Composite Films. Materials 15(6) 2327 (2022). https://www.mdpi.com/1996-1944/15/6/2327