By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Mar 30 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Mar 30 2022In an article recently published in the open-access journal Materials, researchers discussed the bond strength of back-injected structures in a thermoplastic hybrid composite with wood fibers.

Study: Thermoplastic Hybrid Composites with Wood Fibers: Bond Strength of Back-Injected Structures. Image Credit: MT.PHOTOSTOCK/Shutterstock.com

Background

Because of their faster cycle times, lightweight potential, and superior eco-balance, biocomposites consisting of thermoplastic or thermoset matrices with wood or other natural fibers have long been used in the automotive industry. Wood fibers are a good alternative to natural fibers since they have similar qualities and are a single-material solution made from local raw resources.

Wood fibers have not yet been investigated for hybrid processes such as back-injection molding, despite the fact that natural fibers are often employed in hybrid methods and thermoplastic matrices. The binding strength between flat semi-finished products and back-injected structures is an important feature of hybrid composites. A good review of prior applications of composites with wood or natural fibers may be found in a number of studies. For thermoplastic semi-finished goods made from natural fibers, hybrid processing methods such as back-injection are used.

Test procedures for composites and natural fiber-reinforced composites include instrumented puncture impact tests and drop weight tests. However, there are no reports that look at natural or wood fibers in hybrid back-injected composite architectures.

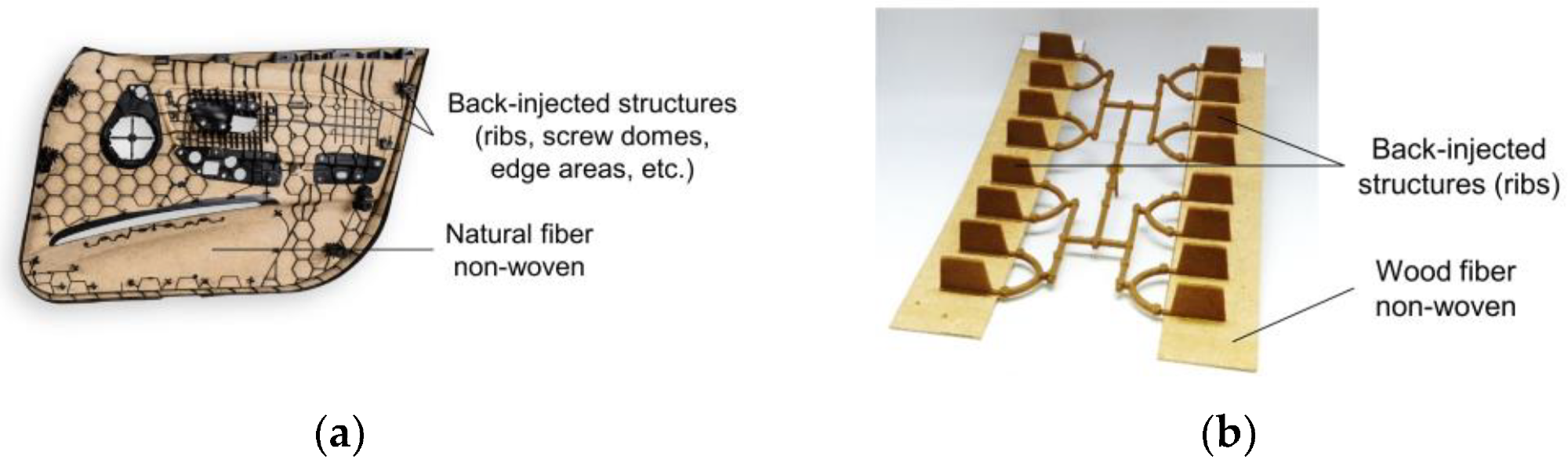

(a) State-of-the-art technology door panel from automotive interior made of a natural fiber non-woven with back-injected structures (ribs, screw domes, edge areas, etc.), image from Yanfeng Automotive Interiors with added labeling; (b) test specimen for analyzing the bond strength via pull-off test, for a non-woven made of wood fibers (spruce) and PP, with the ribs back-injected onto the non-woven. Image Credit: Obermeier, F., et al., Materials

About the Study

In this study, the authors compared the bond strength of an injection-molded rib made of polypropylene (PP) and wood fibers to various non-wovens. Wood fibers (spruce) or natural fibers (hemp, kenaf) were used in the non-wovens, which had a polypropylene matrix. Viscosity measurements, computed tomography testing, and microscopy were used to assess the characteristics of natural and wood-fiber-hybrid composites.

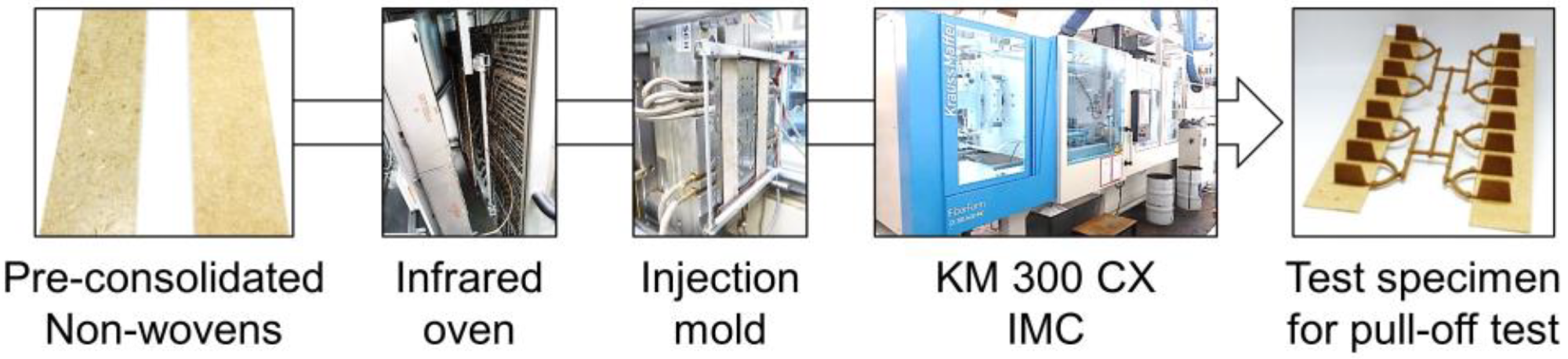

The team presented a comparison of the binding strength of non-wovens with wood fibers and non-wovens with natural fibers in thermoplastic hybrid composites. Non-wovens comprised of wood fiber and non-wovens having natural fiber with a polypropylene matrix were used in the comparison. An injection-molding compounder was used to back-inject the non-wovens with wood-fiber-reinforced, direct-compounded polypropylene.

The authors discussed the development of the non-wovens and back-injected ribs specimens by adjusting various parameters such as injection substance, non-wovens core temperature, and rib geometry. The binding strength of the various specimens was determined using pull-off tests and instrumented puncture impact tests.

Process flow from pre-consolidated non-wovens to test specimen for pull-off tests. Image Credit: Obermeier, F., et al., Materials

Observations

The benchmark built of natural fibers could be challenged by thermoplastic hybrid composites with wood fiber non-wovens. The synergy of compression and injection molding in hybrid composites with wood fibers benefitted the hybrid composites with wood fibers. Back-injection molding blended compression molding's inherent stiffness of the semi-finished fiber-reinforced products with injection molding's design stiffness and high productivity. Wood fiber hybrid composites had slightly lower but almost comparable values.

The experiments revealed that thermoplastic hybrid composites with wood fibers had a lower bond strength than composites with natural fibers, but the mechanical behavior of the two was identical. The binding strength of back-injected ribs was found to be strongly affected by rib geometry and core temperature. For hybrid composites using wood fiber non-wovens, the pull-off force could be raised from roughly 800 N to about 1400 N at a core temperature of 170 °C. In terms of bond strength, there was no discernible difference between the two injection materials.

Back-injection with wood-plastic-composite (WPC) improved the composite's impact behavior. Because the same wood fiber was used for non-wovens and injection material, hybrid composites could be manufactured as a single material solution with domestic raw materials by using a direct compound or WPC. In technical semi-structural applications, thermoplastic hybrid composites containing wood fiber non-wovens were found to be an attractive alternative to natural fibers.

The non-woven core temperature was increased from 20 to 170 °C when the back-injection increased the maximum pull-off force substantially. The natural fibers, i.e., kenaf and hemp from the benchmark material, were estimated to be between 5 and 10 cm long. At 170 °C, the WPC was processed on a normal injection molding machine with a three-zone screw. At the rib base, the initial rib geometry had a radius of 0.8 mm, which resulted in a 229.5 mm2 interface between the rib and non-woven. The second rib geometry featured a foot that was 10 mm wide and 1.3 mm high at the rib base, which resulted in a 450 mm2 interface.

Exemplary specimen after impact test. (a) natural fiber non-woven; (b) wood fiber non-woven; (c) natural fiber non-woven with reinforcement rib (hybrid); (d) wood fiber non-woven with reinforcement rib (hybrid). Image Credit: Obermeier, F., et al., Materials

Conclusions

In conclusion, this study elucidated that the natural and wood-fiber-hybrid composites have extremely similar bond strength trends when similar parameters were used based on the pull-off and instrumented puncture impact tests. In terms of mechanical performance, the authors emphasized that the wood-fiber-reinforced thermoplastic hybrid composites could compete with natural fiber composites, making them a viable alternative in technical semi-structural applications.

The authors also believe that the building industry, the automobile industry, and in particular electric car manufacturers are all potential growth markets for biocomposites.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Obermeier, F., Karlinger, P., Schemme, M., et al. Thermoplastic Hybrid Composites with Wood Fibers: Bond Strength of Back-Injected Structures. Materials 15(7) 2473 (2022). https://www.mdpi.com/1996-1944/15/7/2473