By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Apr 5 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Apr 5 2022In an article recently published in the open-access journal Biomimetics, researchers presented the preparation of mycelium composites reinforced with wood veneer for long-lasting building components.

Study: Wood-Veneer-Reinforced Mycelium Composites for Sustainable Building Components. Image Credit: Cheng Wei/Shutterstock.com

Background

The construction industry has been challenged in recent decades by the constantly growing population and the related demand for homes and construction materials. At the same time, the extra pollution, energy, and waste generated in the production of traditional building materials like cement, steel, and plastics pose serious environmental risks.

The processing of materials widely utilized in the building industry produces the majority of greenhouse gas (GHG) emissions. Natural resource depletion and increased awareness of climate change have prompted researchers and businesses to look for sustainable alternatives to currently utilized materials.

The 4R concept of Reduce, Reuse, Recycle, and Recover is becoming more popular in industries as a way to reduce waste and encourage circular economy models. Growing biological materials from industrial plant waste could be a viable alternative.

Among these, the recent introduction of bio-based composite materials made from mycelium has the potential to change the construction industry. However, its low resistance to tension and bending is one of the most significant restrictions on its employment in the construction industry. Wood, on the other hand, has a long history of being known for its structural strength. Because of its fiber arrangement, it is a naturally tension-resistant material.

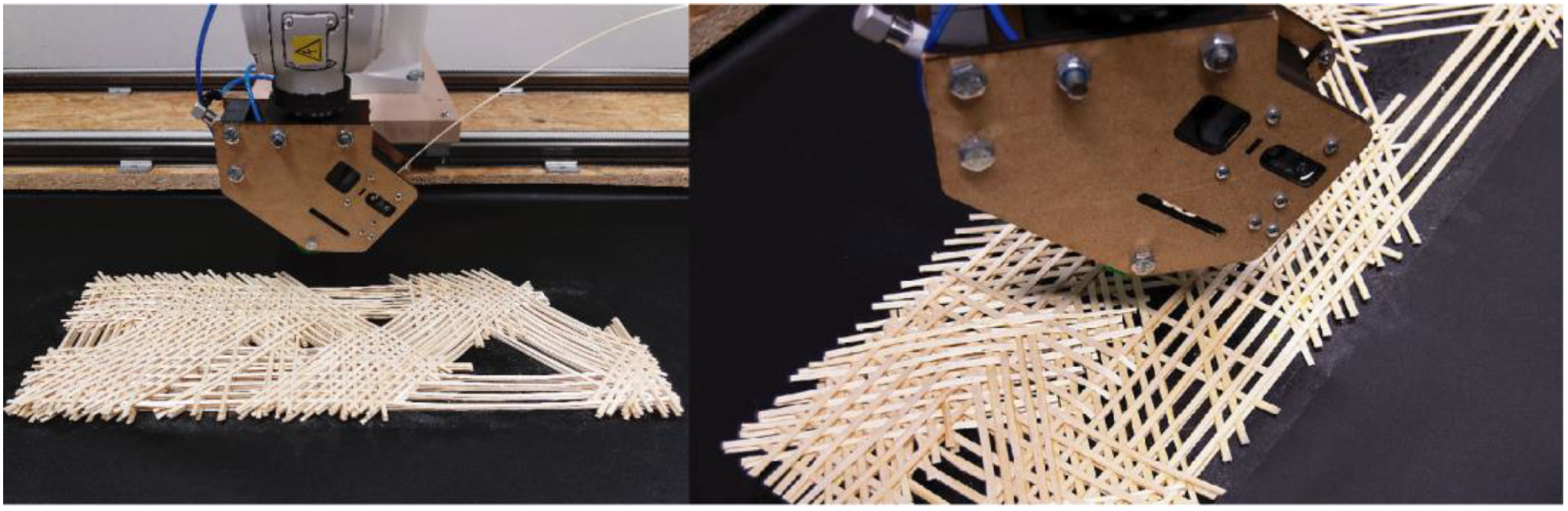

Robotic fiber laying process with processed willow strips from the research project TETHOK—Textile Tectonics for Wood Construction, University of Kassel. Image Credit: Özdemir, E et al., Biomimetics

About the Study

In this study, the authors focused on using unique robotic additive manufacturing procedures to improve the structural performance of mycelium composites for interior usage by incorporating continuous wood fibers into the mycelial matrix as reinforcement.

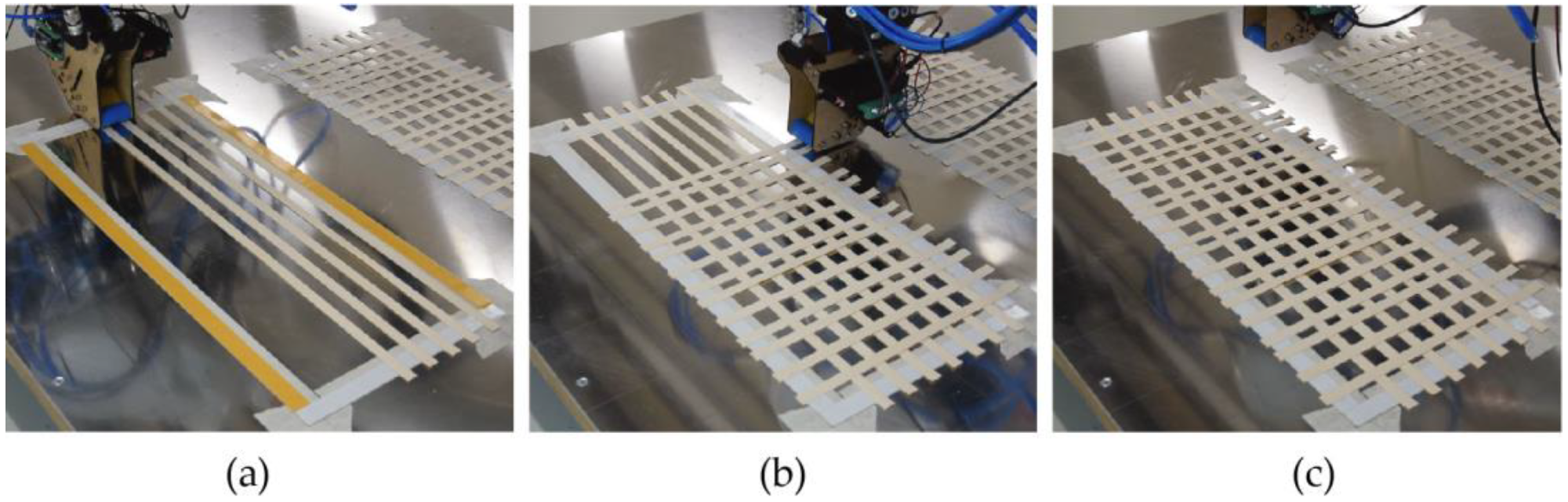

Through physical prototyping and testing, two methodologies were studied and their effectiveness, advantages, and limitations were assessed. A hybrid fabrication method for this composite material system was developed, and the samples were structurally tested to see how compression and reinforcement effect composite strength.

The researchers combined the benefits of each material by utilizing the inherent features of mycelium and wood veneer, as well as investigating the development of unique 100% bio-based mycelium-wood veneer composites with superior mechanical properties.

Compression with heat and pressure, as well as the incorporation of topologically engineered reinforcement inside the mycelium matrix, were the two approaches utilized for enhancing material strength. The fundamental mechanical properties of this new composite were investigated by structural testing on physical prototypes. Compressive strength, flexural properties, and bond strength were investigated on test samples made with several versions of veneer lattices as reinforcement systems.

The team used Ganoderma lucidum and hemp hurds for mycelium growth, as well as maple veneer for strength. The unreinforced samples were compared to the veneer-reinforced samples in pull-out, compression, and three-point bending tests. The tensile strength of the reinforcement joints was also tested.

The potential benefits of combining wood veneer and mycelium's distinct material properties, as well as methods for the design and production of architectural components were discussed, and preliminary experiment results showing the effect of veneer reinforcements on increasing bending resistance were presented. The focus was to find strategies to increase this composite's structural performance for architectural applications while retaining acceptable levels of acoustic performance.

Robotic fiber laying process: (a) Fiber laying in direction one; (b) Fiber laying in direction two; (c) Completed 2D lattice. Image Credit: Özdemir, E et al., Biomimetics

Observations

A unique wood-veneer-derived mycelium-based composite material as a green and sustainable alternative to traditional building materials with suitable applications in the construction industry was successfully developed. Both procedures for enhancing the bending resistance of the given composites by combining compression and a topologically engineered veneer lattice with pressure and heat proved to be effective.

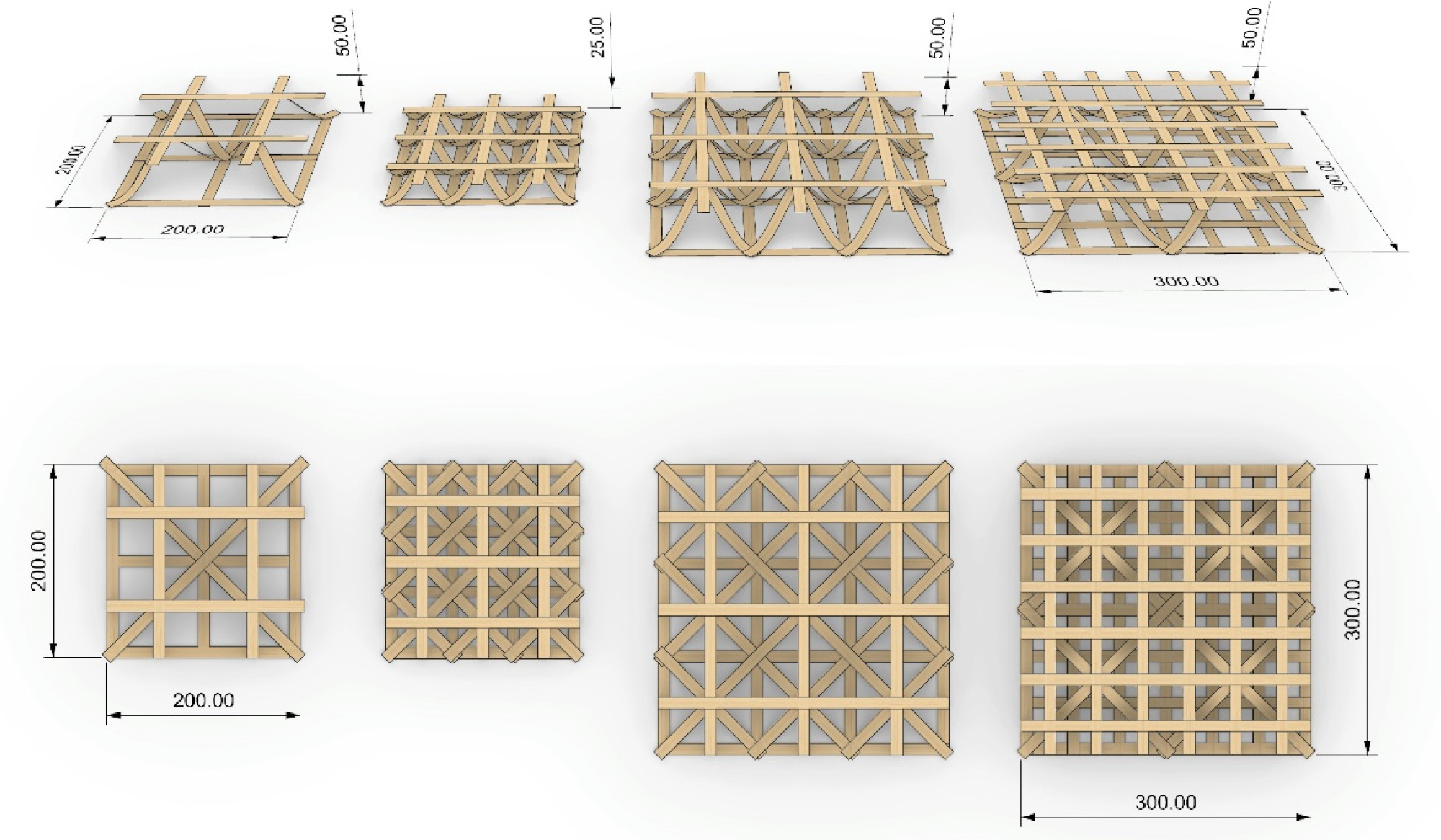

It was discovered that the density and arrangement of veneer lattices as reinforcing systems are inextricably linked. A single layer of the low-density veneer lattice placed at the center of the mycelium block produced the best results for lightweight blocks.

The high-density lattice and two low-density lattices at the top and bottom of the block helped to increment the flexural strength of the block from approximately 0.17 MPa to 0.19 MPa, whereas the flexural strength of the unreinforced block was slightly lower, about 0.16 MPa and 0.13 MPa, respectively. A shear failure occurred in the samples having two low-density lattices, which had poor flexural strength and elastic modulus.

The dense boards having one low-density lattice at the center followed the same pattern as the lightweight blocks and incremented the flexural strength to higher than two times that of the unreinforced dense boards, from about 10 MPa to 25 MPa. In comparison to the unreinforced dense boards, the dense boards having one high-density lattice in the center exhibited no significant change in flexural strength. When comparing the two approaches, thick boards had a higher overall flexural strength.

3D lattice layout studies (dimensions in mm). Image Credit: Özdemir, E et al., Biomimetics

Conclusions

In conclusion, this study elucidated that the resulting unique wood-veneer-reinforced mycelium composite was 100% bio-based. The reinforced samples had better bending resistance, and the reinforcement joints were stronger than the material itself.

The authors emphasized that the dense boards reinforced with a single low-density lattice are the most suitable for applications requiring flat components and stronger bending resistance, and lightweight blocks reinforced with one low-density lattice would be acceptable for more complex designs that do not require significant bending resistance.

They mentioned that this study offered the foundational material inputs for the system's large-scale development and the next step will be to create a digital model that combines material properties, geometrical variations, and acoustic analyses to optimize and evaluate various design options within a single digital computational framework.

They also believe that the wood-veneer-reinforced mycelium composites could be a potentially environmentally friendly and sustainable alternative to traditional building materials with architectural applications.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Özdemir, E., Saeidi, N., Javadian, A., et al. Wood-Veneer-Reinforced Mycelium Composites for Sustainable Building Components. Biomimetics 7(2) 39 (2022). https://www.mdpi.com/2313-7673/7/2/39