Scientists have reported the investigation of adhesive inter-layer interactions in perovskite solar cells. Published in the journal ACS Applied Energy Materials, the new research has been contributed to by scientists from Worcester Polytechnic University in the US state of Massachusetts.

Study: Adhesion in Perovskite Solar Cell Multilayer Structures. Image Credit: Sophon Nawit/Shutterstock.com

Improving Perovskite Solar Cells

Lead halide perovskite solar cells have shown huge promise as renewable energy harvesting devices. These devices display high power conversion efficiency and possess the advantage of low-cost production compared to conventional technologies.

Solution processing methods have traditionally been used in their manufacturing process, but challenges exist with producing perovskite solar cells with these processes. Stability issues, difficulty in fabricating patterned multilayer devices, challenges with the formation of large film areas, and poor reproducibility of film morphology all hinder the manufacture of cells with these processes.

Vapor deposition has been widely proposed to address the challenges with conventional perovskite solar cell manufacture. The use of vacuum and the ability to control deposition parameters provides the potential to produce high chemical-purity perovskites.

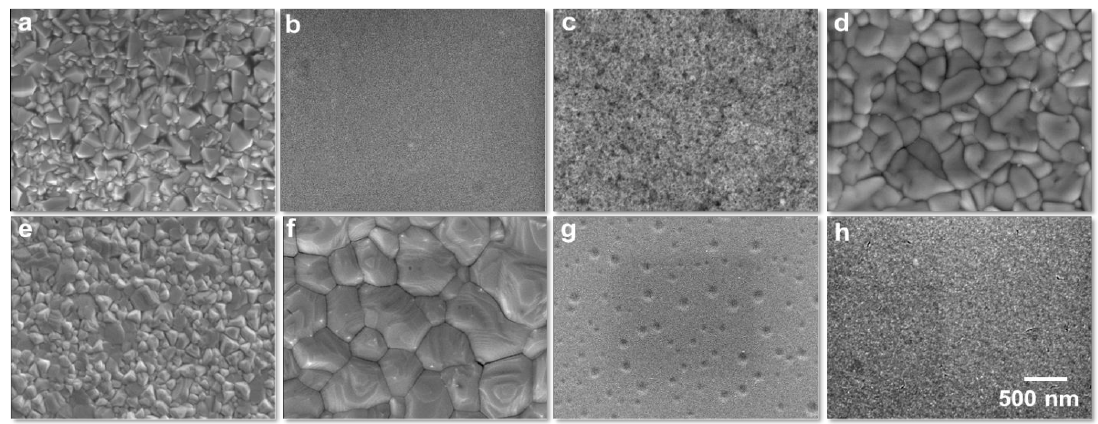

SEM images of individual layer: (a) FTO-coated glass, (b) compact TiO2, (c) mesoporous TiO2, (d) vapor deposited MAPbI3, (e) solution deposited MAPbI3, (f) solution deposited FA-rich perovskite, (g) SpiroOMeTAD, and (h) gold. Image Credit: Ichwani, R et al., ACS Applied Energy Materials

Currently, some lead halide perovskites with moderate mechanical performance have been reported in the literature, such as moderate Young’s moduli, toughness, and hardness values. However, devices are hindered by brittle interfaces between the layers of planar perovskite solar cells and their adjacent films and insufficient interfacial toughness. Due to the multilayer architecture of perovskite solar cells, interfacial robustness can significantly impact their charge carrier transport performance.

The Study

Previous studies have been conducted into the interfacial robustness of these renewable energy harvesting devices. Research has indicated that surface chemistry and underlying toughness mechanisms have an influence on the interfacial fracture toughness of materials.

However, the authors of the new study in ACS Applied Energy Materials have stated that, to their knowledge, there is a lack of research on the measurement of interlayer adhesion that has relevance to developing improved perovskite solar cells. Insufficient adhesion can lead to issues such as delamination and device failure. The authors have noted that a fundamental understanding of the adhesion at the interfaces of these devices is needed in research.

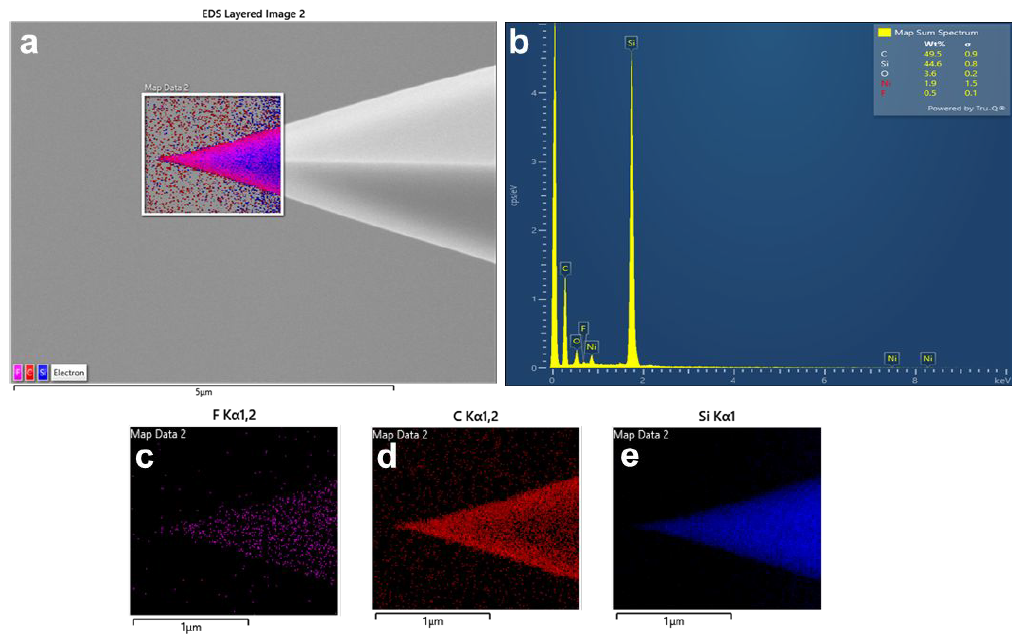

(a) Representative EDS elemental mapping of SpiroOMeTAD coated-AFM tip, (b) EDS spectrum of detected elements on the tip. Elemental mapping of (c) Fluorine, (d) Carbon, and (e) Silicon. Image Credit: Ichwani, R et al., ACS Applied Energy Materials

The researchers have investigated the interlayer adhesion in perovskites manufactured by various deposition techniques. The adhesive interactions were quantified in the study using atomic force microscopy, a powerful analytical technique. Interlayer adhesion was evaluated by elucidating the pull-off forces in samples, allowing the authors to rank the interactions. Additionally, the effect on perovskite morphologies of crystallization conditions was investigated in the paper.

The correlation between interfacial adhesive forces and device performance and charge transport resistance was elucidated by the authors. The research revealed relevant information on the devices which will help to optimize them and overcome traditional issues faced by researchers in the field of renewable energy generation.

Results of the Research

Atomic force microscopy revealed the presence of dense, tightly packed nanometer-sized grains, with the fabrication method affecting the size of grains in the perovskites. Smaller grains are produced by vapor deposition than solution processing. Surface roughness increases with increased grain size.

The research results indicated that perovskite surface roughness has a relationship with force interactions at the interfaces with ETL and HTL layers, with increased surface roughness increasing the interlayer adhesion. Increased surface roughness increases the interfacial contact area and, thus, enhances charge carrier collection. Moreover, structures display less pronounced hysteresis.

Power conversion efficiency is increased by enhanced interfacial and interlayer adhesion in perovskite solar cells manufactured with solution processing. Vapor-deposited perovskite solar cells display lower power conversion efficiency, and this is related to the lower interfacial adhesion of these devices. The authors have noted that to improve the charge transport abilities of devices, low series resistance is favorable as it is related to lower internal resistance. More efficient charge transport improves the performance of devices.

Implications

The research has several implications which are important for the design of robust perovskite solar cells with improved interfacial adhesion. The robustness of interfaces can be ranked by adhesion measurements, which is crucial for the optimal selection of layers in perovskite solar cells. Proper layer selection will lead to improvements in performance and reliability.

Fabrication methods are important parameters as they affect the surface morphology of perovskite solar cells, which influences the interfacial and interlayer adhesion of these devices. Contacts and charge transport are influenced by enhanced adhesion. Further improvements in interfacial adhesion will improve the performance, reliability, and scalability of devices.

The research has also demonstrated the simplicity and suitability of atomic force microscopy for the analysis and categorization of interlayer adhesion in perovskite solar cells. Investigating the effects of different solution processing techniques such as roll-to-roll deposition and dip coating has been identified as a promising future research direction by the authors.

Further Reading

Ichwani, R et al. (2022) Adhesion in Perovskite Solar Cell Multilayer Structures ACS Applied Energy Materials | pubs.acs.org. Available at: https://pubs.acs.org/doi/10.1021/acsaem.2c00430

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.