In an article recently published in the journal Energies, authors from Italy reviewed and summarized recent advances in nanorefrigerants. They highlighted characteristic features of nanofluids and offered valuable insights into their preparation. The authors also elucidated the destabilization and sedimentation mechanisms.

Study: Fouling Behavior and Dispersion Stability of Nanoparticle-Based Refrigeration Fluid. Image Credit: Kateryna Kon/Shutterstock.com

Nanofluids are known for their heat transfer abilities. Despite their potential for industrial applications, their instability is a bottleneck for practical implementation. Thus, investigations on enhancing their stability and reusability are significant in current research.

Background

Nanofluids are heat transfer fluids containing a colloidal suspension of nanoparticles (NPs) in base fluids. Although many characteristic features of nanofluids are useful in industrial use, their consideration for practical implementation is crucial. Additionally, the instability of nanofluids leads to nanoparticle sedimentation and accumulation of unwanted materials on heat transfer surfaces hampering the overall performance of electronic appliances.

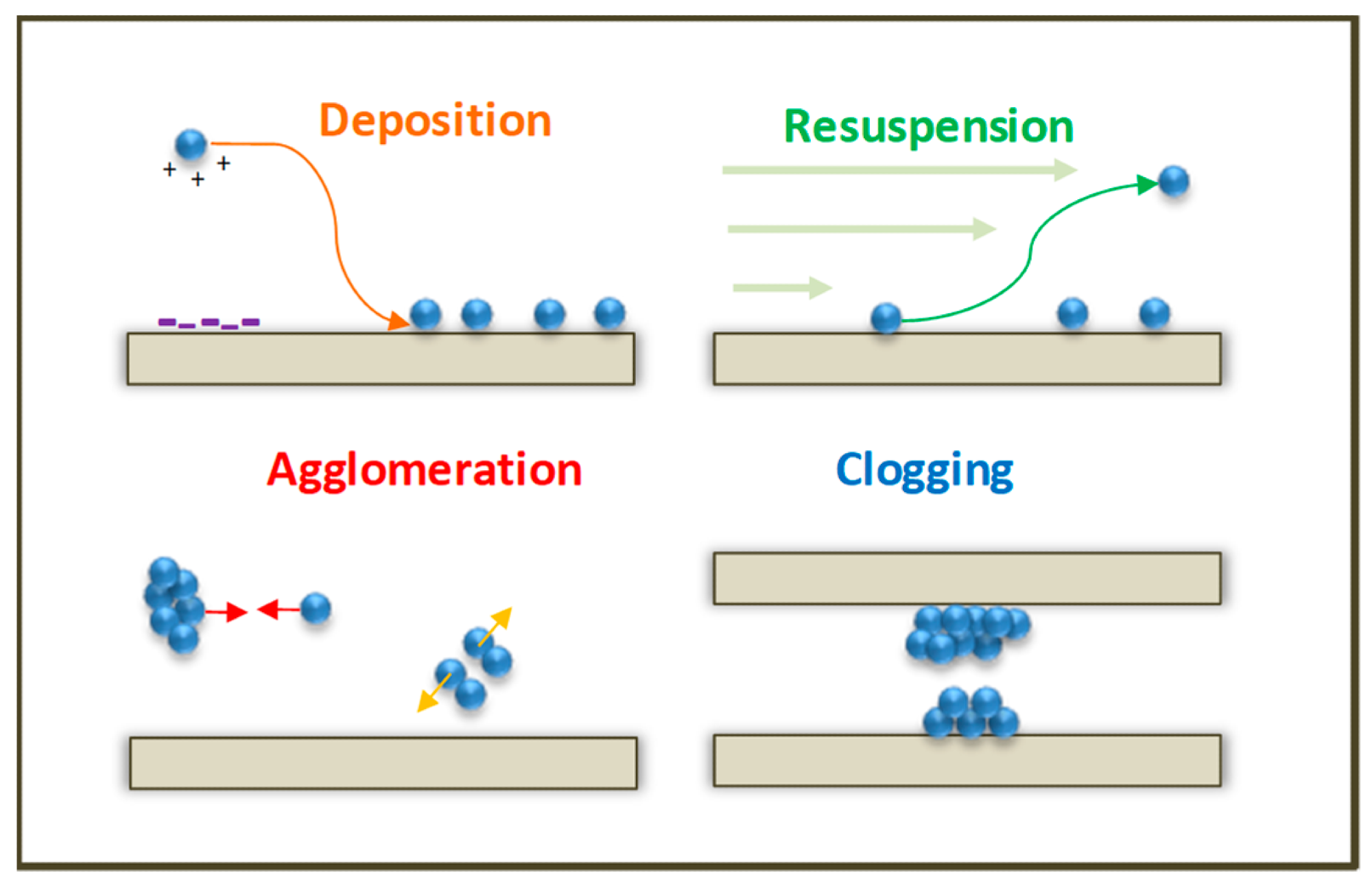

Fouling is a problem in nanofluids caused by the aggregation and sedimentation of NPs, due to their surface activity. This phenomenon impedes the stability of nanofluids. Moreover, its mitigation or prevention remains a challenge to researchers.

The four elementary phenomena of fouling. Image Credit: Ponticorvo, E et al., Energies

The Review Findings

Nanofluid stabilization implies improving NP's stability in a base fluid via chemical or mechanical methods. The hydrophilicity or hydrophobicity of the NPs determines the type of base fluid, which is either polar or nonpolar. The NPs with hydrophilic nature (like graphene or oxides of selective metals) can easily dissolve in polar solvents like water.

On the other hand, hydrophobic NPs need nonpolar fluids like oils. Both these cases are devoid of stabilizer addition. However, hydrophobic NPs stabilization in hydrophilic solvents and contrariwise need additional functionalization and chemical tunings.

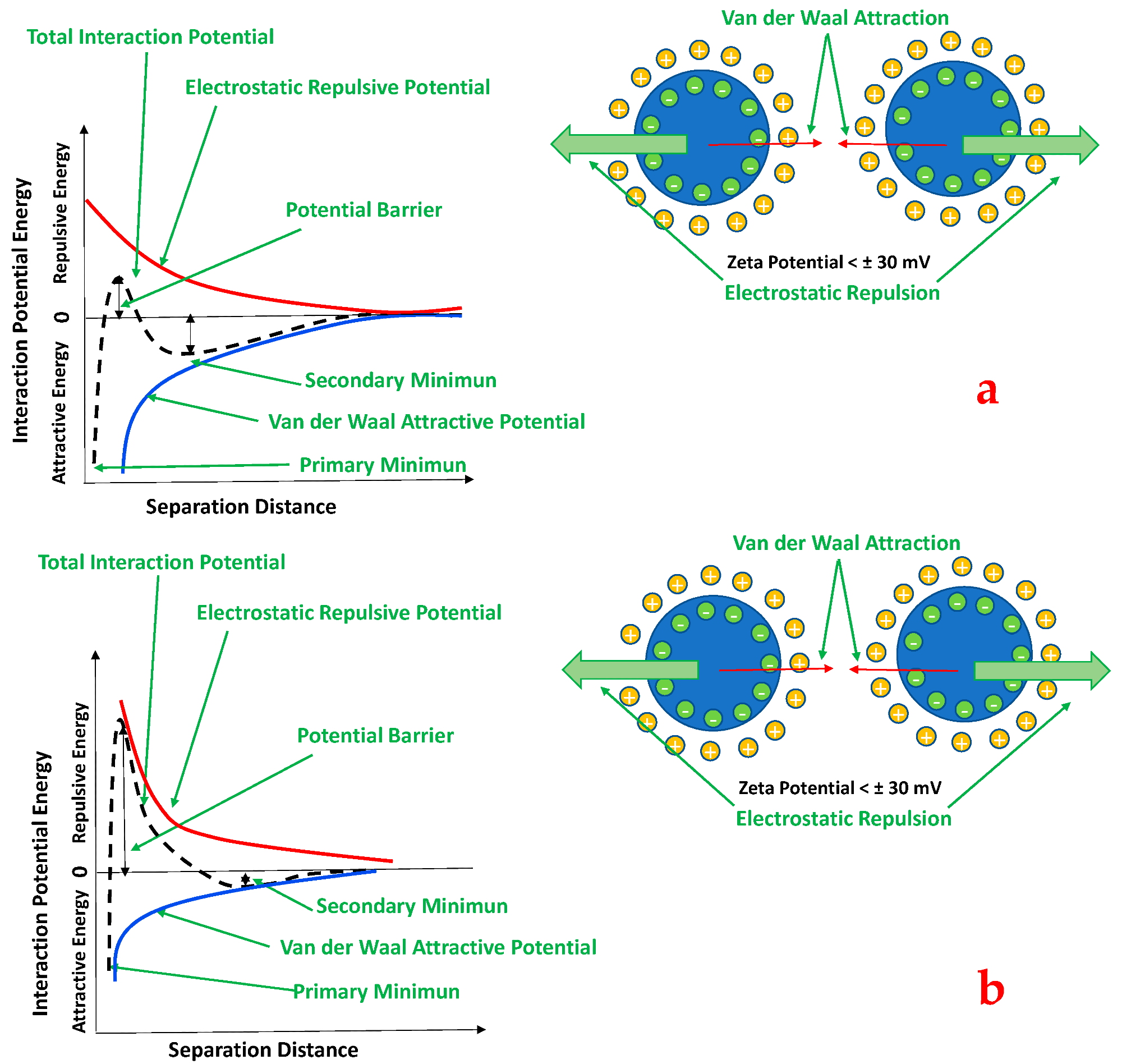

Additionally, employing mechanical approaches such as ball milling, vibration and ultrasonication can reduce the aggregate size of NPs and enhance the stability of nanofluids. Further, either electrostatic stabilization or steric stabilization can aid in achieving chemical stability.

The stability of nanofluids determines their physical and chemical properties, which are influenced by the suspended NPs. Nanofluid stability implies that the NPs should not form aggregates and sedimentation in the base fluid. The deposits of nanoparticles can obstruct the microchannel circuit leading to improper functioning of devices, thus compromising the beneficial effects of nanofluids.

The size and surface activity of NPs make them more prone to aggregation and sedimentation, resulting in increased viscosity, pumping cost, and thermal stability reduction in nanofluids. Nonetheless, their heat transfer coefficients and thermal conductivity reduce energy consumption in electronic appliances. Hence, nanorefrigerants are eco-friendly alternatives to conventional refrigerants.

The size, shape, chemical nature, and concentration of NPs in nanofluids determine their performance. The NPs used in nanofluids may comprise pure metals and metal oxide or may also be carbon-based. The mixing of NPs in the base fluid may be a one or two-step procedure comprising NP preparation followed by dispersion.

Further, the long-lasting dispersion stability of NPs in the base fluid is the key to the thermal conductivity of nanofluids. To this end, diamond NPs dispersed in oil make a good nanofluid for boiling heat transfer in refrigeration systems over metal or metal oxide-based NPs. However, for the practical implementation of diamond-based nanofluids in refrigerating systems, further investigations on diamond NPs aided nucleate boiling heat transfer is required.

Schematic diagram of the potential energy as a function of the NPs’ distances in two cases: (a) low potential barrier, and (b) high potential barrier. Image Credit: Ponticorvo, E et al., Energies

Recent Progress

Carbon nanotubes (CNTs) are more prone to agglomeration, resulting in the degradation of nanofluid thermal activity. Thus, the functionalization of hydrophilic groups at the ends and sidewalls of CNTs stabilizes them in water. To this end, Talaei et al. prepared carboxylic acid (COOH) functionalized multi-walled carbon nanotubes (MWCNTs) to use in a two-phase closed thermo-siphon, thus obtaining homogeneity and increased thermal conductivity.

Park et al. recently added CNTs to commonly used refrigerants 1,1 dichloro-2,2,2 trifluoro ethane (R123) and 1,1,1,2-tetrafluoroethane (R134a) and measured their nucleate boiling heat transfer coefficients, the results obtained revealed a 36% enhanced heat transfer.

Owing to their semiconductor nature, cupric oxide (CuO) based nanofluids have good thermal properties. Hence their application in base refrigerants improves heat transfer characteristics and cooling capacities. Therefore, Sun and Yang prepared 1,1-dichloro-1-fluoroethane (R141b)-based nanorefrigerants using copper (Cu), aluminum (Al), aluminum oxide (Al2O3), and CuO NPs. They observed enhanced heat transfer coefficients in as-prepared nanorefrigerants over conventional refrigerants.

Although the study conducted by Mahbubul et al. on R123/titanium oxide (TiO2) nanorefrigerants did not yield positive results, Bi et al.'s switch to using R134a/ TiO2 reduced the energy consumption in the refrigerator by 26% over the R134a/ polyester (POE) system.

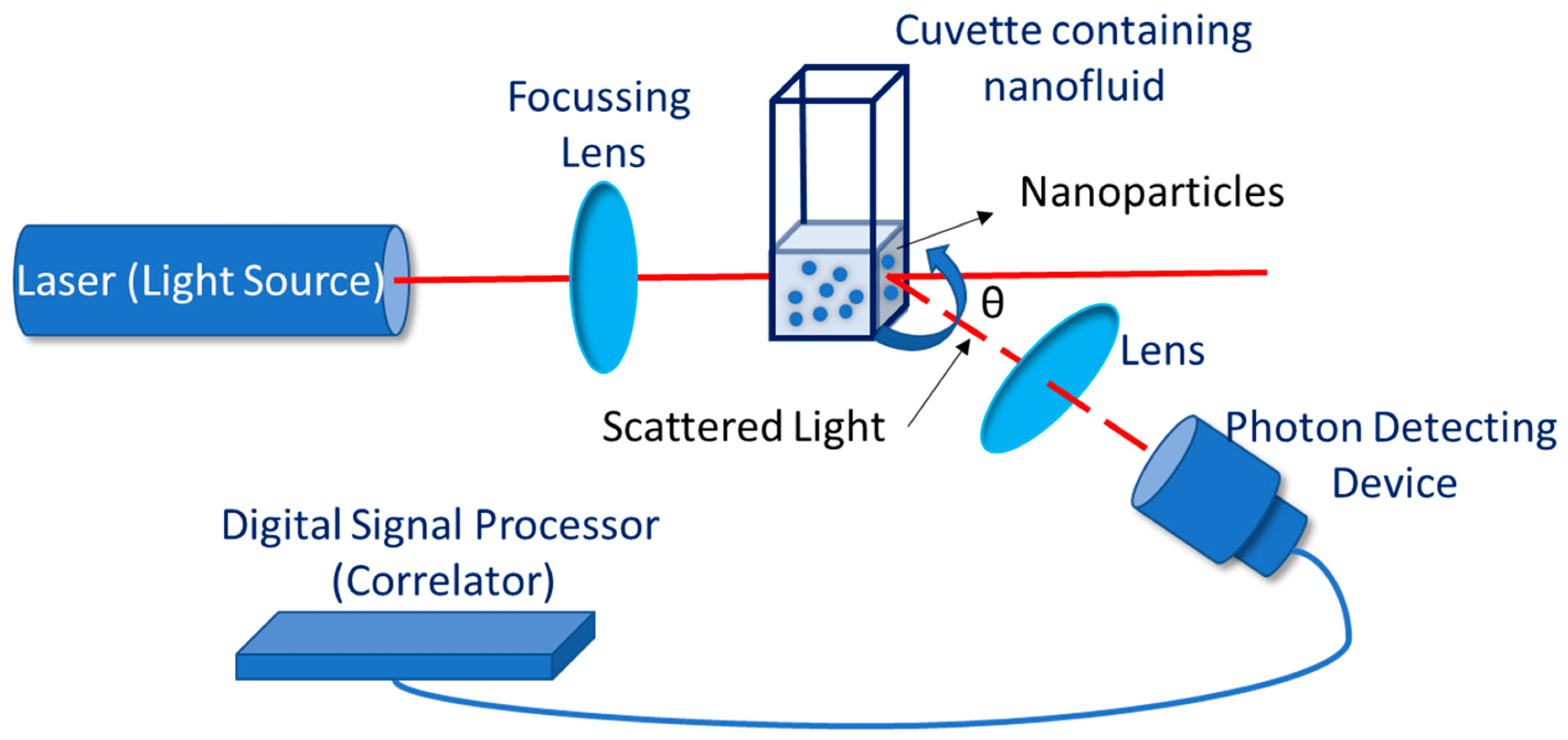

Scheme of dynamic light scattering measurement. Image Credit: Ponticorvo, E et al., Energies

Conclusion

Effective heat transfer is a prerequisite for the industrial application of nanofluids to reduce energy consumption. Nanorefrigerants improve heat transfer coefficients or thermal conductivity in refrigeration systems and enhance overall performance. Nevertheless, despite their efficiency, the heat transfer mechanism in nanofluids still remains unclear.

Although there are previous reports on the increase in thermal conductivity with increasing NP concentration to base fluid, further increases after specific concentrations led to stability problems and a reduction in heat transfer. Additionally, challenges that remain unresolved for nanofluid’s industrial applications include fouling, erosion, and production cost. Thus, the current research scope is on developing NPs with efficient fluid dispersion.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Ponticorvo, E., Iuliano, M., Cirillo, C. et al. Fouling Behavior and Dispersion Stability of Nanoparticle-Based Refrigeration Fluid. Energies. 15, 9, 3059 (2022). https://www.mdpi.com/1996-1073/15/9/3059.