Over a third of the world’s population lives in drylands, where water is scarce. A new technology developed by scientists and engineers at the University of Texas at Austin might be able to help residents access safe drinking water in these areas.

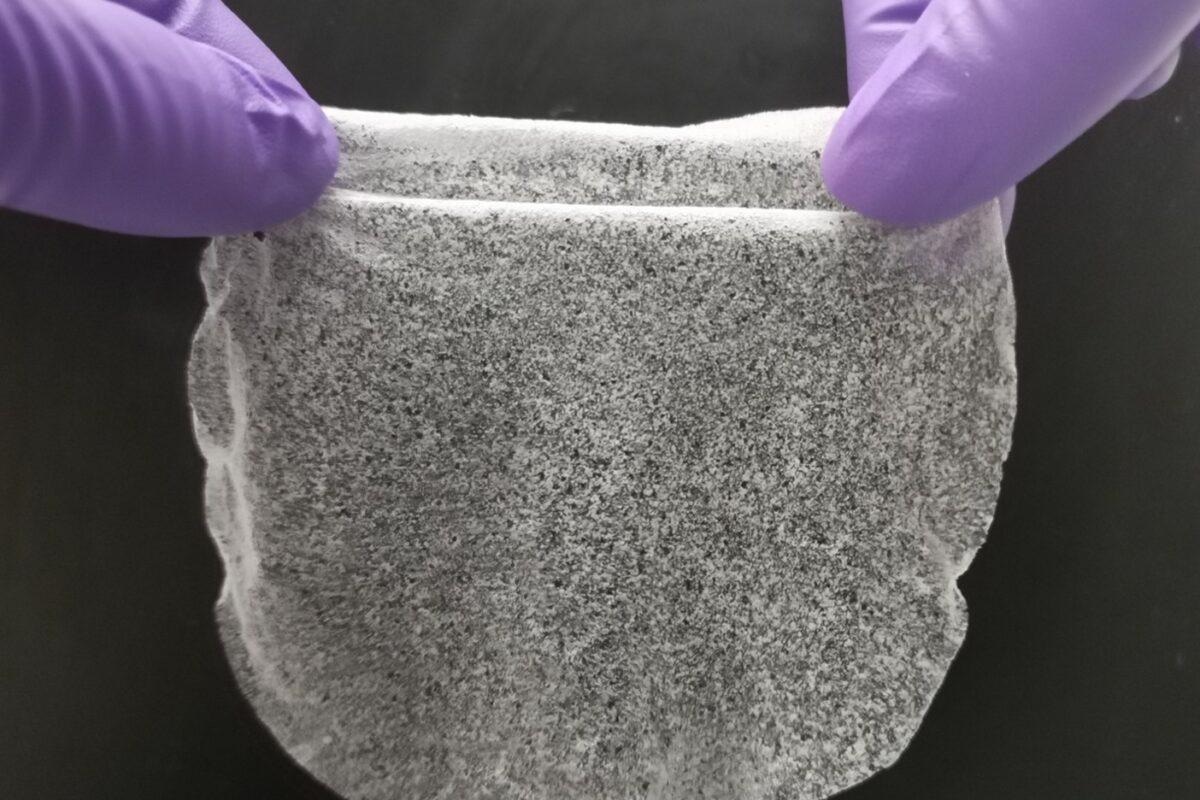

An example of a different shape the water-capturing film can take. Image Credit: The University of Texas at Austin.

An example of a different shape the water-capturing film can take. Image Credit: The University of Texas at Austin.

The researchers created a low-cost gel sheet comprised of common materials that can draw water from the air, even in arid conditions. A single kilo of the ingredients that allow this reaction costs about $2/kg, and it can create more than 6 L of water each day in locations with less than 15% relative humidity and 13 L in situations with up to 30% relative humidity.

The study builds on the team’s prior achievements, such as the capacity to extract water from the atmosphere and use that technology to construct self-watering soil. These technologies, on the other hand, were created for high-humidity conditions.

This new work is about practical solutions that people can use to get water in the hottest, driest places on Earth. This could allow millions of people without consistent access to drinking water to have simple, water generating devices at home that they can easily operate.

Guihua Yu, Professor, Materials Science and Mechanical Engineering, Walker Department of Mechanical Engineering, Cockrell School of Engineering

The paper was published in Nature Communications.

As a major hydrophilic (attracted to water) skeleton, the researchers employed renewable cellulose and konjac gum, a ubiquitous household product. Gum’s open-pore nature helps it capture moisture faster.

Another developed component, thermo-responsive cellulose with hydrophobic (water-repellent) interaction when heated, aids in the quick release of collected water, reducing overall energy input to create water.

Alternative methods of extracting water from arid air are often inefficient and ineffective. Although 6 L may not seem like a lot, the researchers claim that optimizing thicker films, absorbent beds, or arrays might dramatically improve the quantity of water they produce.

According to the researchers, the reaction is straightforward, which makes scaling it up and gaining broad adoption easier.

This is not something you need an advanced degree to use. It is straightforward enough that anyone can make it at home if they have the materials.

Youhong “Nancy” Guo, Study Lead Author and Postdoctoral Researcher, Massachusetts Institute of Technology

The flexible film can be molded into a variety of forms and sizes, relying on the user’s requirements. The gel precursor containing all of the necessary chemicals poured into a mold is all that is required to make the film.

The gel takes 2 minutes to set simply. Then, it just needs to be freeze-dried, and it can be peeled off the mold and used immediately after that.

Weixin Guan, Lead Researcher, Cockrell School of Engineering

The Defense Advanced Research Projects Agency (DARPA) of the United States Department of Defense supported the research, which includes drinking water for soldiers in dry locations. However, due to its simplicity, the researchers believe that it can one day be purchased at a hardware store and used in people’s homes.

The project was directed by Yu. Guo and Guan collaborated on synthesis, sample characterization, and device demonstration experiments. Chuxin Lei, Hengyi Lu, and Wen Shi are the other members of the team.

Journal Reference:

Guo, Y., et al. (2022) Scalable super hygroscopic polymer films for sustainable moisture harvesting in arid environments. Nature Communications doi/10.1038/s41467-022-30505-2.