By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.May 25 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.May 25 2022In an article recently published in the journal Additive Manufacturing Letters, researchers discussed the laser-melting preparation of a 316L stainless steel (SS)-based copper composite.

Study: Synthesis of a 316L Stainless Steel – Copper Composite by Laser Melting. Image Credit: Pedal to the Stock/Shutterstock.com

Background

Although heat propagation inside homogenous solids is diffusive by nature, heat can be steered through solid matter via the route of least resistance. Within metal foam heat sinks, the utilization of anisotropy in thermal conductivity and permeability has been advocated for improving heat transfer rates.

Furthermore, anisotropic thermal conductivity is expected to aid in the reduction of parasitic losses caused by axial heat conduction within the compact heat exchangers. Various methodologies for altering the heat conductivity of alloys and metals have been employed. None of these methods are suitable for scaling up directional heat flux control tactics in metal components.

Metal matrix composites (MMCs) are made from ball-milled powders using laser powder bed fusion (LPBF). A new hybrid LPBF approach was recently proposed, which utilized piezoelectric inkjet technology to make an ODS 304 SS alloy by doping yttria precursors into a 304 SS powder bed before the laser consolidation. The advantage of this method is the ability to adjust material characteristics selectively inside different areas of the powder bed, allowing material properties to be controlled within the tool's build volume.

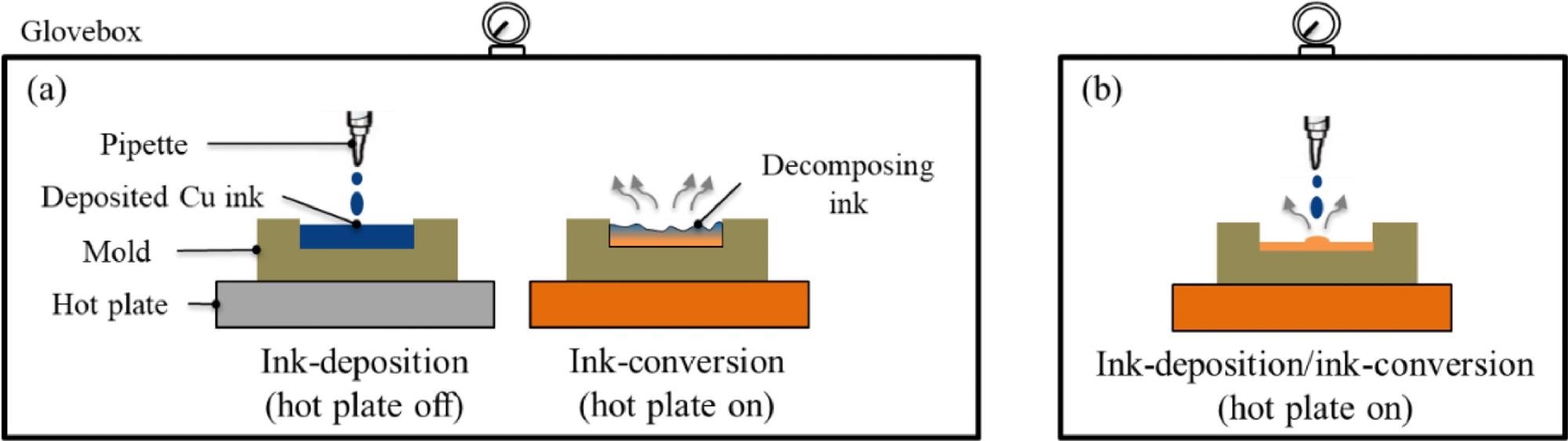

Schematic diagram of (a) post-heating and (b) heated-bed methods of ink conversion. Image Credit: Murray, J. W et al., Additive Manufacturing Letters

About the Study

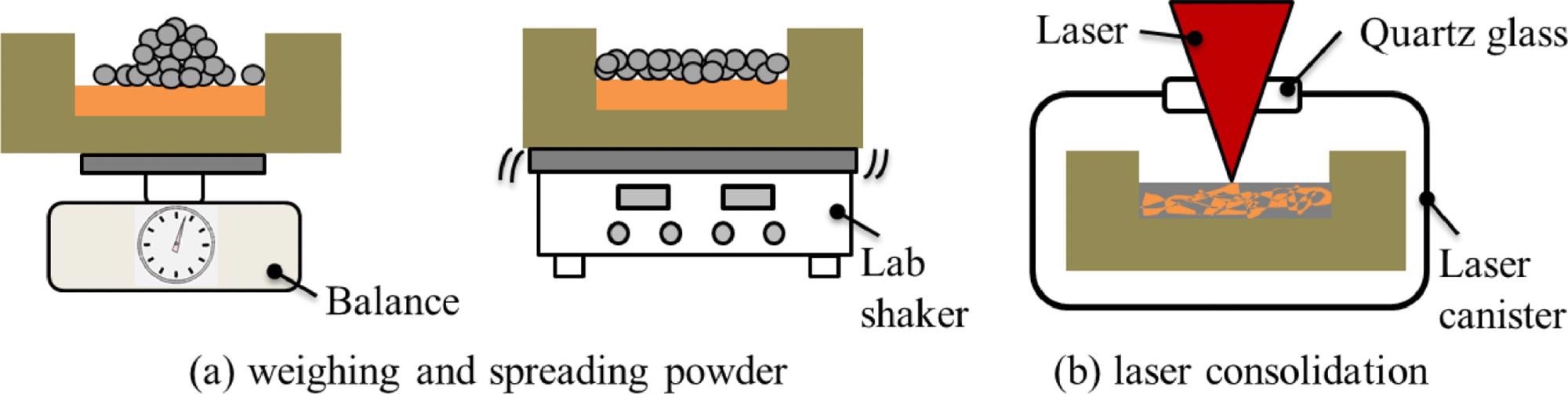

In this study, the authors employed a jettable Cu ink to demonstrate a laser melting approach for the production of a metal matrix composite with a better thermal conductivity than 316L stainless steel. To simulate a hybrid inkjet-powder bed fusion technique for doping the stainless-steel powder bed with Cu precursor ink, a new canister was employed to manage the oxygen level during laser processing.

The team created a 316L stainless steel – Cu composite in a simulated laser powder bed fusion environment by utilizing a jettable copper ink. A chemical reactor that used the new hybrid inkjet-LPBF approach was prepared to take advantage of the directional thermal conductivity to lower the reactor's total size and weight. The feasibility of creating the composite material utilizing jettable ink was demonstrated.

The researchers focused on the precursor Cu ink selection and the procedures for producing composite test products to characterize the material's density, microhardness, composition, and thermal diffusivity. Two ink candidates were chosen based on the oxidation stability, low or no additive requirements, compatibility with an inkjet printhead, and minimal residue after conversion.

CufAMP, the first ink, used copper formate (Cuf) as a copper salt. Vinyl trimethyl copper (II) hexafluoro acetylacetonate (Cu (hfac) VTMS) was another precursor ink. A pilot experiment was conducted to see if flash evaporation and thermal decomposition of the ink caused more contamination of the copper due to chemical by-product entrainment than traditional drying and thermal decomposition.

Two tiny coupons were created using the two ways and compared in terms of microstructure to ascertain the effect of the conversion method. With a load of 500 gf and a dwell time of 15 s, Vicker's microhardness (HV) was performed on the cross-sections of the fusion zone for both coupons.

Diagram of experimental setup and process steps that were repeated for fabricating the 316L SS – Cu composite coupon produced using the heated bed method. Image Credit: Murray, J. W et al., Additive Manufacturing Letters

Observations

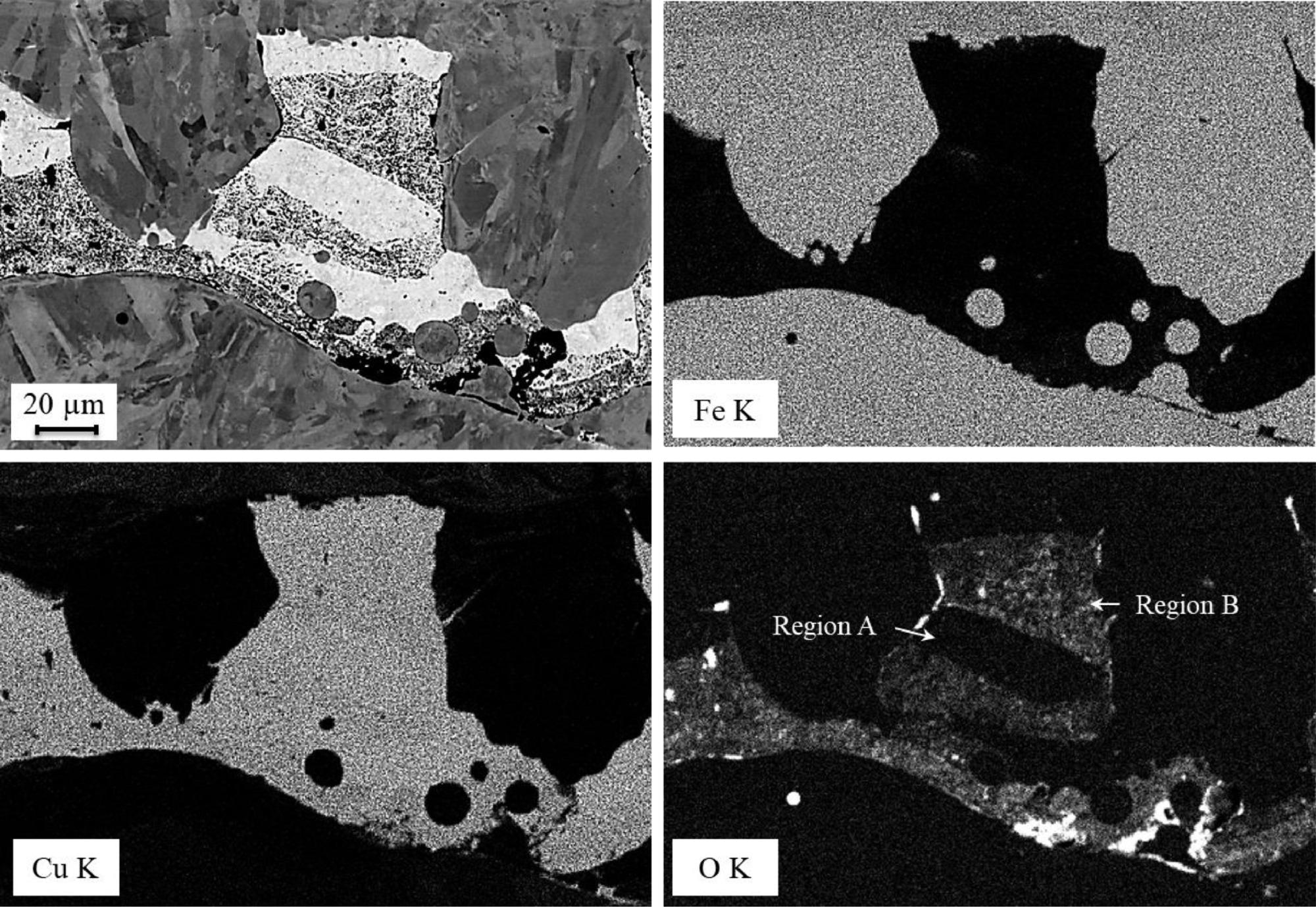

The composite's thermal conductivity was found to be 187% higher than that of 316L stainless steel, while its microhardness was found to be 39% lower. Microstructural studies revealed that the reduction in interfacial cracking could improve the composite's thermal conductivity and mechanical performance. For directed heat flow within heat exchangers, a selective thermal conductivity increase in 316L stainless steel was required. The composite's effective thermal conductivity was measured at 41.0 W/m.K, which was 2.9 times that of 316L stainless steel with a 39% reduction in hardness.

When compared to wrought annealed 316L SS, the heated-bed coupon had a microhardness of 123 ± 59 HV, which was a 39% reduction. The final composite had a porosity of 12%, which was attributed to the cavities and cracks at the interface between the SS and Cu phases.

The microhardness of the fusion zone cross-sections was determined to be 110 ± 61 HV and 123 ± 59 HV, respectively, for the post-heating and heated-bed coupons, a 45% and 39% decrease from the 200 HV of wrought annealed 316L SS. Due to the large difference in melting temperatures between Cu and 316L SS of roughly 315°C, cracking in the manufactured composite was produced by liquation cracking as a result of Cu liquation.

BSE image (top left) and elemental maps (Fe, Cu, O) of the post-heating coupon obtained by WDS analysis. Image Credit: Murray, J. W et al., Additive Manufacturing Letters

Conclusions

In conclusion, this study used a jettable Cu ink to demonstrate a new approach for generating a 316L SS–Cu composite with a better thermal conductivity than 316L SS. The composite was made by depositing and converting ink into Cu in a glovebox, then topping it with SS powder, which was then combined and solidified in a laser welder.

Preliminary findings suggested that a methanol-based Cuf-AMP ink may be degraded to pure copper without forming copper oxide in a similar environment to that of an LPBF process. When compared to traditional post-heating procedures, a heated-bed method for ink deposition and conversion produced microstructures with fewer holes and impurities.

The authors mentioned that future research will look into ways to reduce grain size and a better melt and mix of the SS and Cu phases, as well as the composite's mechanical properties.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Murray, J. W., Speidel, A., Spierings, A., et al. Synthesis of a 316L Stainless Steel – Copper Composite by Laser Melting. Additive Manufacturing Letters 100058 (2022). https://www.sciencedirect.com/science/article/pii/S2772369022000329