Scientists from Poland’s Cracow University of Technology and the University of Beira Interior in Portugal have investigated the effect of walnut shells on the properties of geopolymers. Their findings have appeared in the journal Materials.

Study: An Investigation of the Ground Walnut Shells’ Addition Effect on the Properties of the Fly Ash-Based Geopolymer. Image Credit: sahinside/Shutterstock.com

Geopolymers: A Sustainable Development Solution

Sustainable development has become a foremost concern for engineers and scientists. Aside from developing green manufacturing processes and reducing the exploitation of fossil fuels, the development of sustainable and green materials has become a research focus in several sectors.

Geopolymers are increasingly being explored in several industries, including construction. These synthetic inorganic polymers offer advantages over traditional construction materials such as Portland cement in terms of sustainability, reduced carbon emissions, lower energy requirements, reduced need for virgin resources, waste utilization, and circularity.

Many materials have been considered for use in geopolymers. Industrial wastes such as copper slag, fly ash, and synthetic polymers have been explored, along with materials such as red mud and metakaolin. Geopolymers often display better mechanical and thermal properties than their conventional counterparts. Moreover, many geopolymers possess superior corrosion and temperature resistance.

The properties of geopolymers are determined by the raw materials used in their manufacture as well as the type and amount of fillers and activators. Furthermore, controlling manufacturing processes (for example, adjusting temperature and process time) can affect the final properties of geopolymers.

Despite their excellent benefits in terms of sustainability and property enhancement, there are some drawbacks to geopolymers. For instance, the brittleness of geopolymers can lead to reduced tensile stress and flexural strength and can lead to problems such as microcracking.

(a) Fly ash; (b) quartz sand; (c) ground walnut shells. Image Credit: Kozub, B & Castro-Gomes, J, Materials

Fiber-Reinforced Geopolymers

The problems experienced in geopolymer design can be overcome by reinforcing them with fibers. Synthetic fibers have been explored extensively, utilizing industrial waste streams that would otherwise be sent to landfills, incinerated, or disposed of in the environment.

Organic fibers such as polyethylene and polypropylene, natural fibers such as banana, sisal, basalt, and cotton, and inorganic fibers such as glass, steel, and carbon have all been investigated by researchers. Natural fibers have received particular research focus in recent years. They provide engineers and researchers with the possibility of creating low-cost, lightweight geopolymers.

Natural fibers have several benefits compared to polymer and inorganic counterparts. They are recyclable and carbon-neutral, significantly reducing the environmental impact of polymer production. Additionally, the production cost of the raw materials is less than synthetic fibers. Moreover, they are non-toxic and renewable and are easy to process.

There are, however, some drawbacks to natural fibers that hinder the commercial development of geopolymers reinforced with these materials. Geopolymer synthesis is carried out in alkaline conditions, which can degrade natural materials. Consequently, natural fiber-reinforced geopolymers can suffer from weak bonding between geopolymer matrix and aggregates.

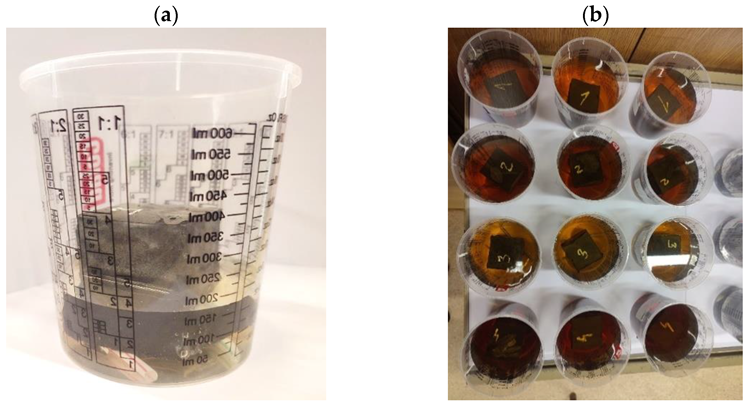

(a) Example sample prepared for water absorption testing—1st day of measurements (flooding the sample to about half of its height); (b) samples fully immersed in distilled water 24 h after starting the tests. Image Credit: Kozub, B & Castro-Gomes, J, Materials

The Study

The authors have evaluated the effect of using ground walnut shell waste on geopolymer mortars for use in sustainable development. This natural waste is used as an aggregate, replacing quartz sand. To assess the proposed aggregates, samples of geopolymer mortars manufactured from fly ash, a commonly used material, were prepared with both walnut shell waste and quartz sand.

Samples with different weight percentages of the proposed aggregate were prepared in the research to examine the effect of walnut shells on geopolymer properties. Tests were performed to analyze geopolymer characteristics such as thermal conductivity, density, bending strength, water absorption, and compressive strength, alongside visually assessing efflorescence. SEM was used to characterize microstructure.

Study Findings

The authors demonstrated several effects on fly ash geopolymers caused by ground walnut shell waste. Generally speaking, the authors concluded that walnut shells could be considered to be effective substitutes for quartz sand in geopolymers.

Walnut shells reduced the flexural and compressive strength of the samples. As the weight proportion of walnut shells increased, these mechanical properties were reduced. Visual efflorescence analysis demonstrated reduced efflorescence, which is a positive effect due to efflorescence negatively affecting the mechanical properties of geopolymers.

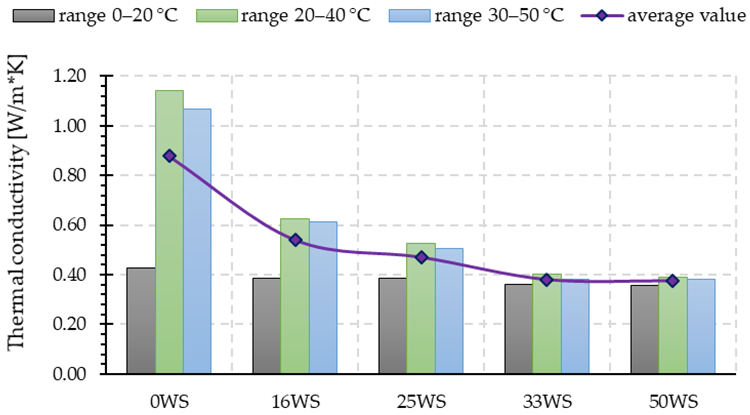

Thermal conductivity over the ranges: 0–20 °C, 20–40 °C, and 30–50 °C for the tested geopolymer composites. Image Credit: Kozub, B & Castro-Gomes, J, Materials

The reduction in efflorescence could be due to the use of fly ash. Part of the sodium in the alkaline solution did not completely combine with the low reactive fly ash, which was free to react with atmospheric carbon dioxide.

The use of walnut shells as an aggregate replacement for quartz sand had other effects on geopolymers. Firstly, absorption increased with higher proportions of additives. Secondly, geopolymer density was reduced, and completely replacing quartz sand with walnut shell halved the geopolymer’s density. Thirdly, the authors observed a marked reduction in thermal conductivity, which makes these composite geopolymers good candidates for insulation materials.

Further Reading

Kozub, B & Castro-Gomes, J (2022) An Investigation of the Ground Walnut Shells’ Addition Effect on the Properties of the Fly Ash-Based Geopolymer Materials 15(11) 3936 [online] mdpi.com. Available at: https://www.mdpi.com/1996-1944/15/11/3936

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.