A paper recently published in the journal Materials demonstrated the feasibility of using non-metallic powder of waste printed circuit boards (PCBs) to enhance the asphalt material performance.

Study: Recycling Non-Metallic Powder of Waste Printed Circuit Boards to Improve the Performance of Asphalt Material. Image Credit: Olegs Petuhovs/Shutterstock.com

Background

The PCB scrap rate has increased significantly in the past few decades owing to the rapid proliferation of electronic products. In recent years, millions of tons of electronic waste (e-waste) were generated globally, and the volume of waste will increase substantially in the upcoming years.

Currently, e-waste, specifically waste PCBs, is directly disposed of through incineration or landfills, which leads to land and air pollution that adversely impacts human health and the environment. The environmental impact due to the direct disposal of e-waste can be mitigated by recycling these wastes in the construction of highways.

E-waste plastic has already been used in several studies to improve asphalt performance. For instance, e-waste powder derived from recovered computer plastics was added to asphalt to increase the rutting resistance, blending temperatures, and viscosity of the binder.

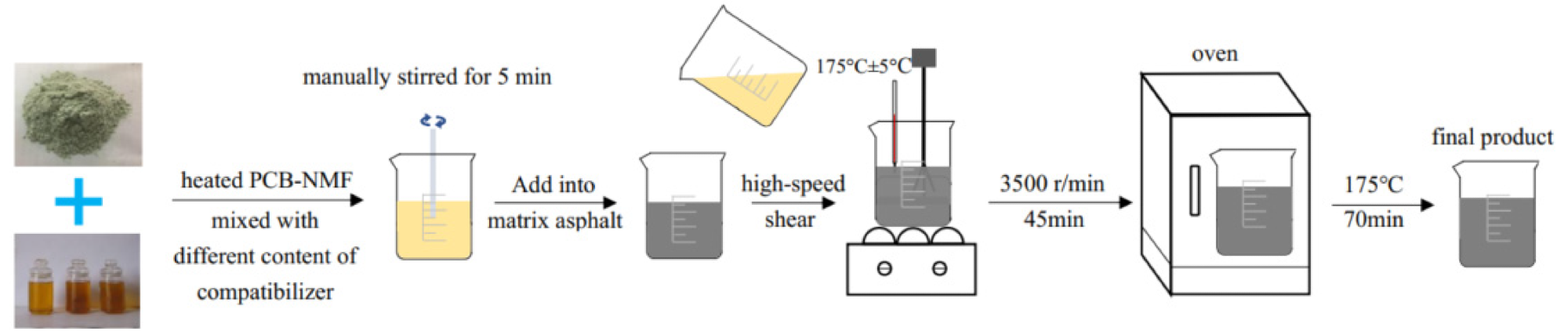

PCB-NMF asphalt preparation process. Image Credit: Li, S et al., Materials

Similarly, asphalt binders modified with cumene hydroperoxide-treated e-waste polymers displayed significant improvements in elasticity and stiffness. The dynamic modulus, fatigue resistance, and rutting resistance of a 5% e-waste plastic powder-modified bitumen increased by 10%, 19%, and 28% at 40 oC, 10 oC, and 40 oC, respectively.

The temperature sensitivity, low-temperature performance, and high-temperature performance of a modified asphalt were increased, while the fatigue life decreased when different amounts of PCB powders were added to the asphalt.

Several studies investigated the feasibility of using non-metallic fraction (NMF) obtained from waste PCBs (PCB-NMF) in the construction of highways. For instance, NMF powder-modified asphalt demonstrated an enhanced rutting resistance and stiffness and reduced ductility and temperature susceptibility.

Additionally, the addition of NMF powder with the smallest particle size led to the highest improvement in equivalent brittle point and softening point (SP) and penetration index of the modified asphalt.

However, the storage stability and compatibility of the PCB-modified asphalt were reduced when the NMF concentration increased above 10% in the asphalt.

Glass fiber and cured epoxy resin are the major components of NMF. Although several studies were conducted on epoxy resin-modified asphalt, studies investigating the application of cured epoxy resin in asphalt mixtures have not been performed until now.

However, several studies were performed on the application of glass fibers in asphalt mixtures. For instance, the application of recycled glass powder (RGP) in asphalt mixtures and bitumen improved the engineering properties of both materials except the toughness index.

The Study

In this study, researchers evaluated the possibility of recycling PCB-NMF in asphalt material using glycerin and tung oil as composite compatibilizers. The addition of PCB-NMF, a polymer composite material, to asphalt can lead to storage instability as its properties differ from that of asphalt. Thus, a compatibilizer comprising 40% glycerin and 60% tung oil was used to improve the compatibility between asphalt and PCB-NMF.

Matrix asphalt no. 70 with properties that satisfied the technical requirements of the Chinese standard test methods of bituminous mixtures and bitumen for highway engineering and PCB-NMF powder particles composed of 40% glass fiber and 60% cured thermosetting epoxy resin with 23 μm average particle size were used as the starting materials.

16%, 12%, 8%, 4%, and 0% compatibilizer was utilized to pre-treat the PCB-NMF. The heated PCB-NMF was initially mixed with the compatibilizer, and the mixture was stirred manually for five minutes. The as-prepared compatibilizer and PCB-NMF mixture were then added to the matrix asphalt.

Subsequently, the PCB-NMF-modified asphalt was synthesized using the high-speed shear method with a 3500 r/min shear rate for 45 min at 175 °C ± 5 °C temperature. The mixture was then placed in the oven for 70 min at 175 °C to obtain the final modified asphalt samples. PCB-NMF-modified asphalt samples with 40%, 30%, 20%, and 10% PCB-NMF were prepared.

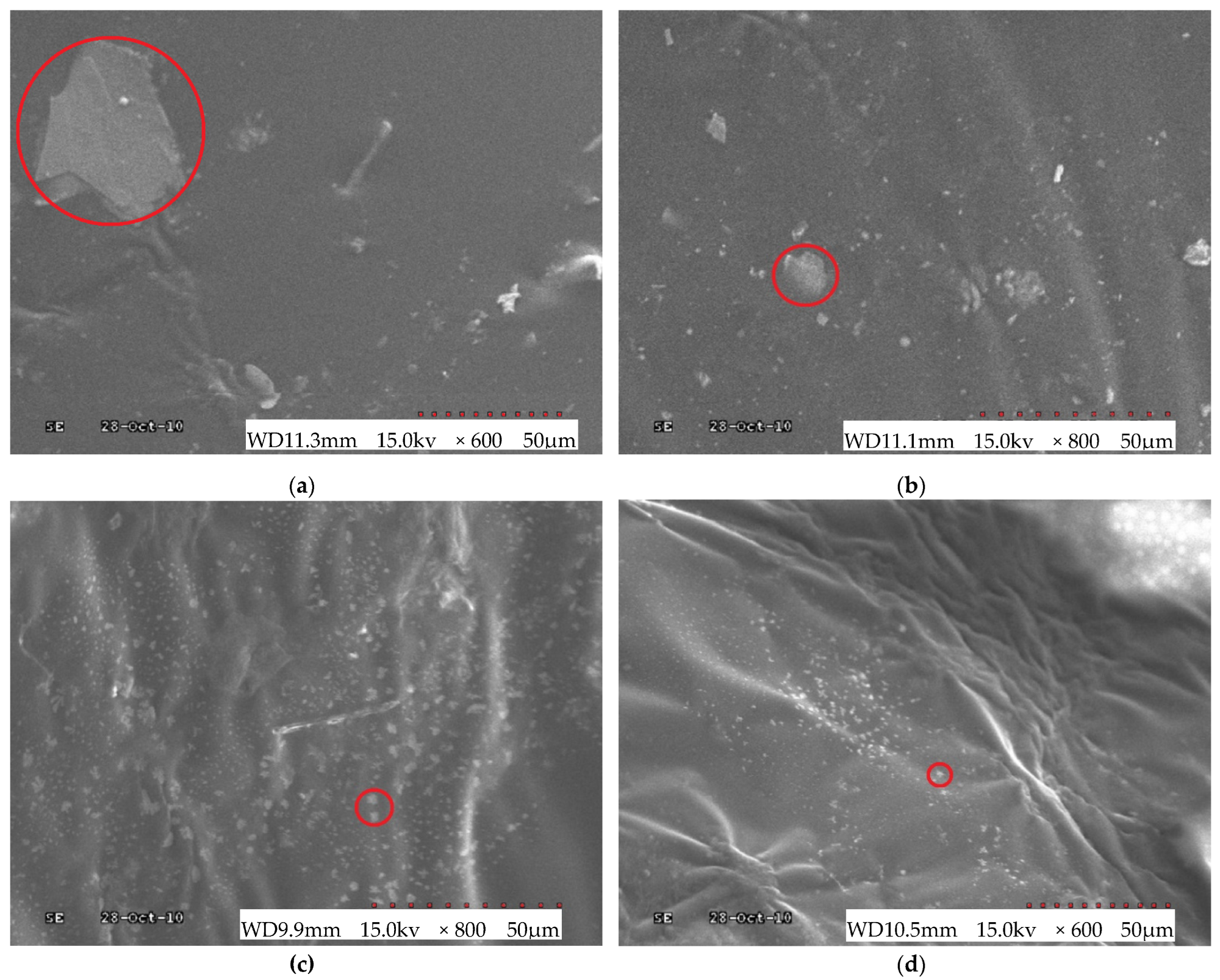

The influence of the compatibilizer on the matrix asphalt and PCB-NMF at different concentrations was assessed using scanning electron microscopy (SEM). The DV2T Brookfield rotational viscometer was employed to determine the PCB-NMF-modified asphalt sample viscosity at 175 °C, 135 °C, and 120 °C.

Researchers also performed the phase separation test and temperature sweep tests to evaluate the storage stability and the dynamic shear rheometric properties of the PCB-NMF-modified asphalt, respectively.

A bending beam rheometer (BBR) was used to assess the low-temperature performance of the PCB-NMF-modified asphalt at −12 °C, −18 °C, and −24 °C, while a Fourier transform infrared (FTIR) spectroscopy was used to investigate the interactions between virgin asphalt and PCB-NMF to understand the PCB-NMF modification mechanism on the asphalt.

SEM of NMF modified asphalt: (a) 0% compatibilizer content (magnitude ×600); (b) 4% compatibilizer content (magnitude ×800); (c) 8% compatibilizer content (magnitude ×800); (d) 12% compatibilizer content (magnitude ×600). Image Credit: Li, S et al., Materials

Observations

PCB-NMF modified asphalt materials were synthesized successfully. The compatibilizer consisting of glycerin and tung oil helped in dispersing the PCB-NMF powder particles in the asphalt materials, which improved the compatibility between the virgin asphalt and PCB-NMF.

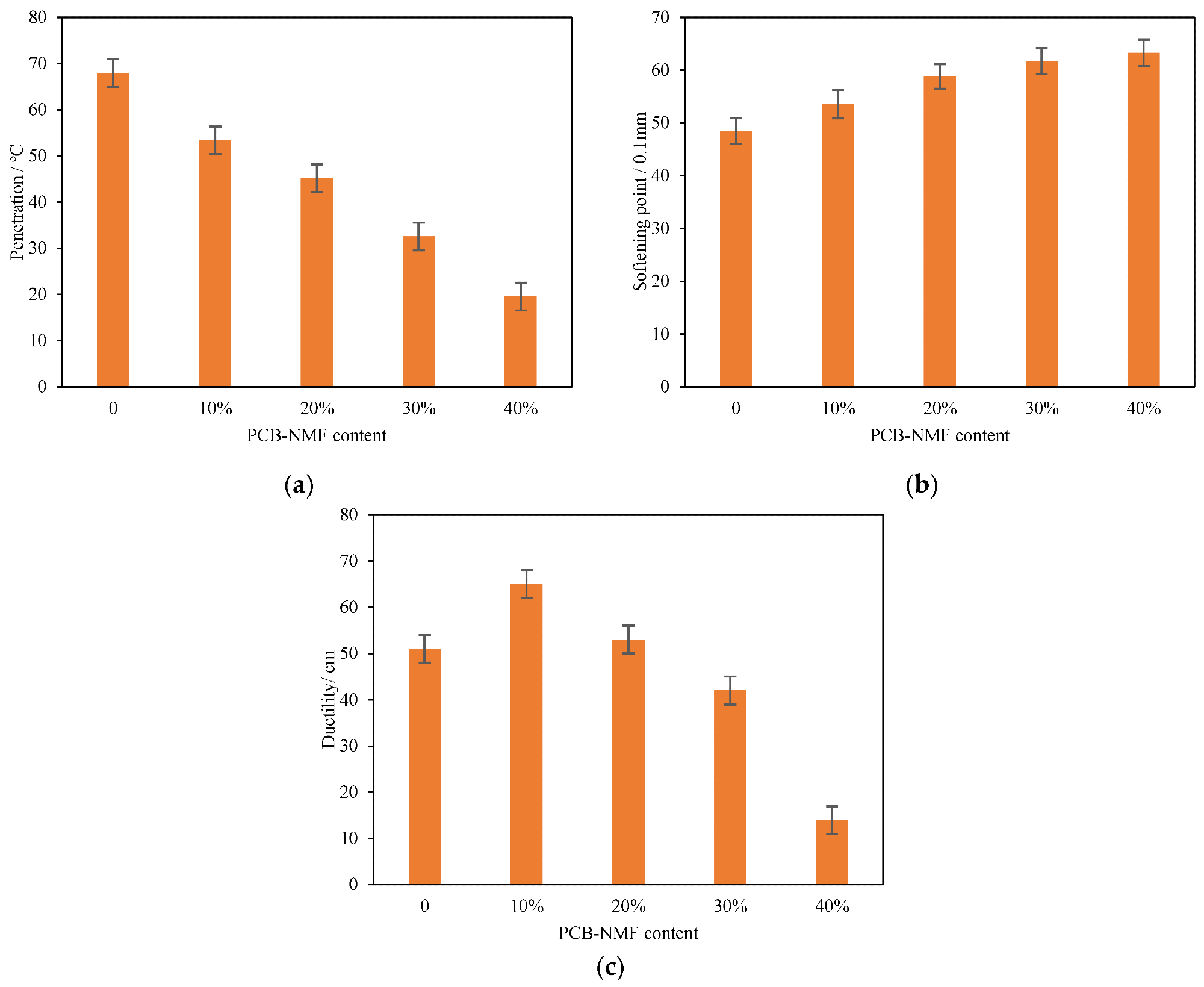

The optimal compatibilizer concentration in the PCB-NMF was 8% based on the softening point difference (SPD), ductility, penetration, and SP tests. The addition of PCB-NMF increased the SP, viscosity, and dynamic modulus of the modified asphalt.

The optimum concentration of the PCB-NMF powder in the asphalt was 30% after the comprehensive evaluation of the influence of different concentrations of the powder particles on the dynamic shear properties, viscosity, ductility, SP, and penetration of the modified asphalt. The PCB-NMF considerably improved the temperature sensitivity, rutting resistance, and stiffness of the asphalt materials at 30% concentration.

The PCB-NMF decreased the m-value and increased the creep stiffness of the asphalt. Although 30% PCB-NMF-modified asphalt displayed sufficient thermal cracking resistance at −12 °C, the resistance weakened at −18 °C and −24 °C, indicating that the PCB-NMF was ineffective in improving the resistance at low temperatures. No chemical reaction was observed between the matrix asphalt, compatibilizer, and PCB-NMF.

0%, 10%, 20% 30%, and 40% of PCB-modified asphalt tested for: (a) penetration, (b) softening point, and (c) ductility. Image Credit: Li, S et al., Materials

Taken together, the findings of this study demonstrated the feasibility of using a PCB-NMF modifier to improve the asphalt material properties and offered insights into innovative recycling of waste NMF in pavement engineering, leading to a potential reduction in e-waste generation and environmental pollution.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Li, S., Sun, Y., Fang, S. et al. Recycling Non-Metallic Powder of Waste Printed Circuit Boards to Improve the Performance of Asphalt Material. Materials 2022. https://www.mdpi.com/1996-1944/15/12/4172