A paper recently published in the journal Polymers reviewed the effect of natural compounds on the antifungal and antibacterial properties of polyurethane (PUR).

Study: Natural Additives Improving Polyurethane Antimicrobial Activity. Image Credit: Marina Demkina/Shutterstock.com

Background

Disinfectants are commonly used in places such as healthcare facilities and food and pharmaceutical industries to maintain sterile and hygienic conditions due to their robust antimicrobial activity and cost-effectiveness. However, these chemicals display high toxicity to both human health and the environment, which can lead to bronchial irritation from inhalation, and general caustic effects.

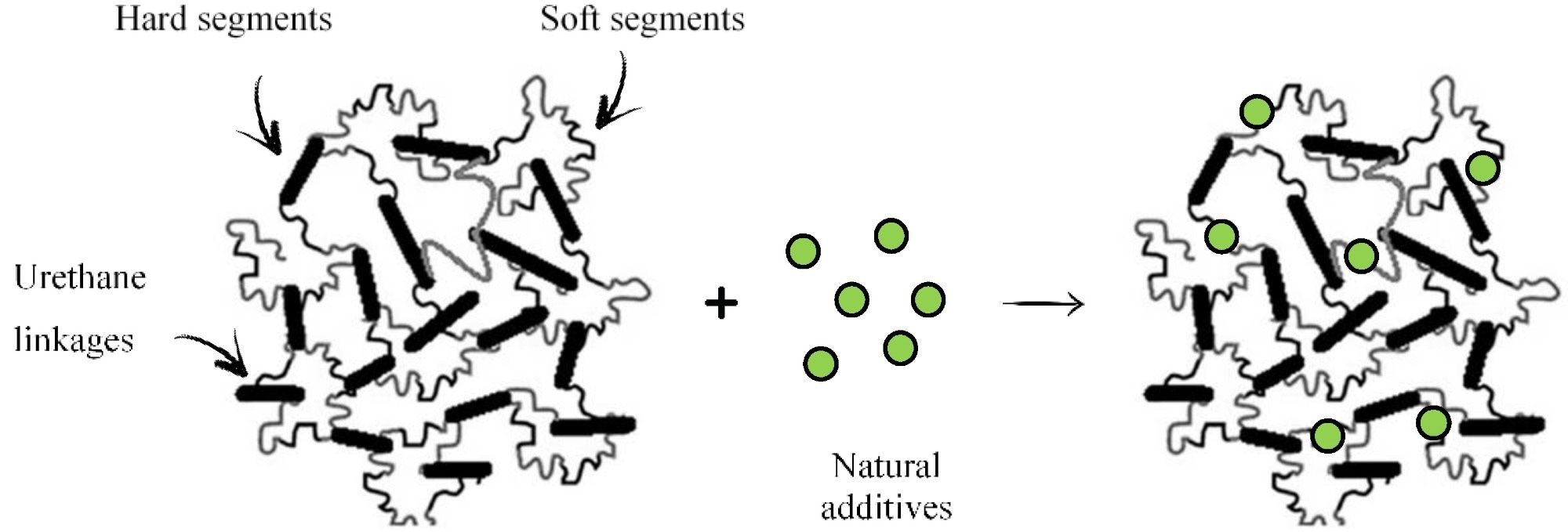

The impact of the natural additives’ addition on the crosslinking density of PUR composites. Image Credit: Sienkiewicz, N et al., Polymers

Natural antimicrobial additives can be considered a suitable alternative to chemical antimicrobials such as disinfectants. The bio-resistance potential of different kinds of spices, herbs, and plant extracts, such as thymol, carvacrol, eugenol, and cinnamaldehyde, has already been confirmed in several studies.

Polymers must be modified and treated to inhibit bacterial and fungal growth as they are susceptible to microorganism adhesion. The growth of microorganisms on polymers can lead to human health issues during the storage and use of polymers, which necessitates the application of additives that eliminate fungi, bacteria, and viruses.

PURs with antifungal and antibacterial properties have gained considerable attention in recent years. Several studies have demonstrated the feasibility of using natural extracts as additives to PURs to improve their antibacterial, antifungal, and antiviral properties.

The Study

In this study, researchers reviewed the effect of different natural modifiers and additives on the antibacterial, antifungal, and antiviral properties of PURs.

PURs Modified with Antimicrobial Compounds

The antiseptic properties of PUR were improved by modifying the polymer with cinnamaldehyde (CA). Antibacterial microporous polyurethane scaffolds (MPTLs) were synthesized in the shape of fine layers with 0.5–5% of CA. 3.5% CA-modified MPTLs demonstrated the highest antibacterial effect against Salmonella, Eschecheria coli (E. coli), and Pseudomonas syringae pv.

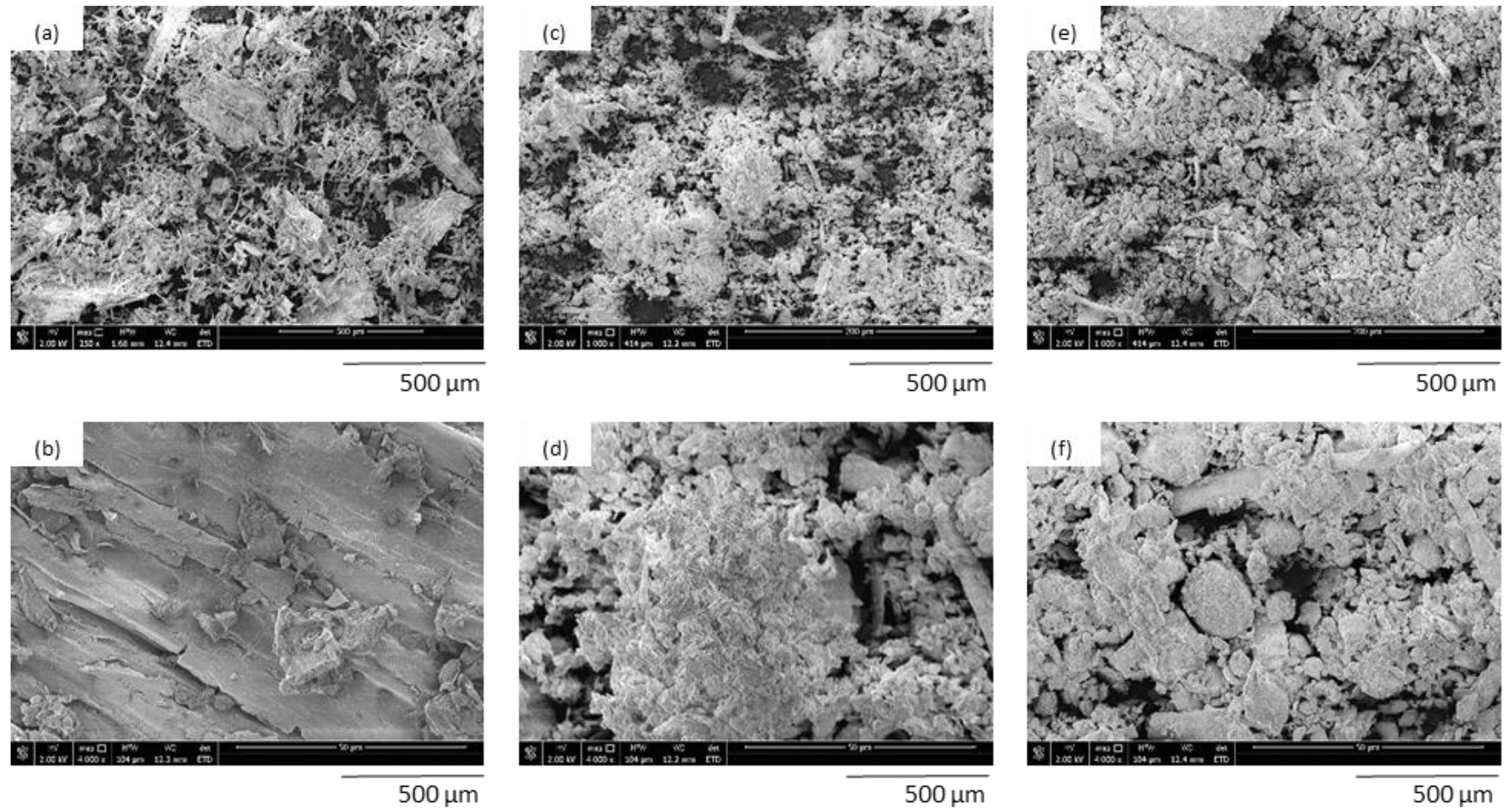

SEM images of lavender fillers: (a,b) non-functionalized lavender, (c,d) lavender functionalized with kaolinite, (e,f) lavender functionalized with hydroxyapatite. Image Credit: Sienkiewicz, N et al., Polymers

The antiadhesive and antiseptic properties of PUR were obtained simultaneously by immobilizing 0.5% heparin and 0.5-2% chitosan on PUR samples through a stepwise method. The synthesized samples displayed antibacterial activity against Gram-negative Pseudomonas aeruginosa (P. aeruginosa) and E. coli and Gram-positive Staphylococcus epidermidis (S. epidermidis) and Staphylococcus aureus (S. aureus), and a satisfactory bacterial adhesion results with a considerable decrease in the number of bacteria in both chitosan- and chitosan-heparin-modified PUR samples.

Antibacterial wound dressing materials were synthesized by coating Syzygium aromatic extract/clove oil on thermoplastic PUR nanofibers mats. The synthesized PUR nanofibers coated with two mg cm−2 clove oil displayed antibacterial activity against E. coli and S. aureus.

Thymol-loaded ethanol-soluble PUR as nanofibrous membranes also demonstrated antibacterial properties. A dressing material was prepared using PUR-thymol nanofibrous membranes with 8, 6, 4, and 2 wt% of thymol. The nanofibrous membranes composed of thymol, fluorinated PUR, and PUR showed significant antibacterial activity. Membranes with eight wt.% thymol displayed the highest antibacterial activity against E. coli and S. aureus.

Functional green nanocomposite films with antibacterial properties were synthesized using Salvia-based waterborne polyurethane-urea (WBPUU) dispersions with cellulose nanocrystals (CNC). The nanocomposite films displayed antibacterial activity against P. aeruginosa, E. coli, and S. aureus. The Salvia-based WBPUU films demonstrated a bacteriostatic effect against all selected bacteria after one day incubation period. 3-5 wt% Salvia-based WBPUU films displayed the highest inhibition effect on all studied bacteria.

A new antimicrobial and biocompatible PUR-based material with effective wound healing properties were prepared for wound dressing application. The PUR-hyaluronic acid (PU-HA) nanofibrous wound dressing was synthesized with various concentrations of ethanolic extract of propolis (EEP).

Propolis is typically used to prepare several pharmaceutical materials with antiprotozoal, antiviral, antifungal, and antibacterial properties. The PUR-HA/2% EEP and PUR-HA/1% EEP demonstrated a higher antibacterial activity against E. coli and S. aureus compared to other samples. The PUR-HA/1% EEP sample also demonstrated considerably greater biocompatibility for L929 fibroblast cells compared to the PUR-HA/2% EEP sample.

Two PUR types based on 1,4-butandiol, hexamethylene diisocyanate, and polycaprolactone were synthesized using a two-step polymerization method. Curcumin was then added to the prepared PURs as a modifier in different amounts. The curcumin-modified PUR showed satisfying antibacterial and mechanical properties, indicating the feasibility of using the material in wound dressing applications.

Malva sylvestris extract-modified PUR/carboxymethylcellulose nanofibers were prepared to heal diabetic wounds. The synthesized samples containing 15% Malva extract displayed 69.83 and 70.66% antibacterial activity against S. aureus and E. coli, respectively, and 95.05 ± 0.24% wound healing rapidity by day 14.

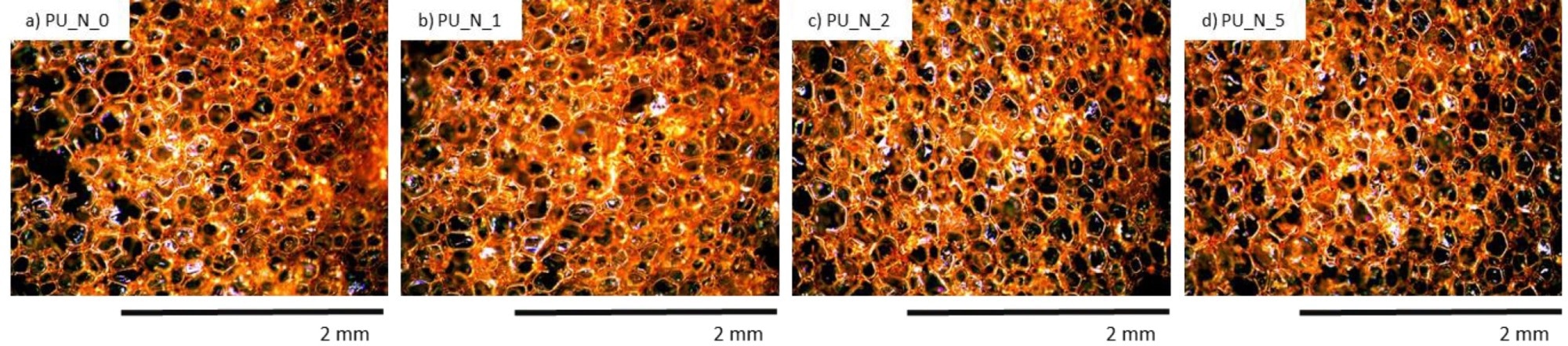

Morphology of PUR composite foams after 7 days of UV aging. Image Credit: Sienkiewicz, N et al., Polymers

PUR Foams Filled with Antimicrobial Compounds

Lavender filler-modified PUR foams were synthesized by adding two wt.% lavender functionalized with hydroxyapatite (HA) and kaolinite (K) to PUR samples. The K and HA-functionalized lavender fillers were utilized as a reinforcing material during the PUR foam synthesis. The PUR composites reinforced with non-functionalized lavender, K-functionalized lavender, and HA-functionalized lavender demonstrated good antibacterial properties against Bacillus subtilis, S. aureus, and E. coli. However, no antifungal activity was observed in any lavender-reinforced PUR composite sample.

Nutmeg filler-modified PUR composite foams were synthesized successfully by reinforcing the PUR samples with 5, 2, and 1 wt.% of nutmeg filler. The incorporation of nutmeg fillers significantly enhanced the antibacterial properties of the synthesized PUR composites against E. coli and S. aureus. Specifically, the composite with 5 wt.% nutmeg filler demonstrated the highest antibacterial activity.

Syzygium aromaticum/cloves were used as organic fillers to reinforce permanent PUR materials. Soybean-oil-based PUR composite foams were reinforced successfully with 5, 2, and 1 wt.% of clove filler. All samples displayed antibacterial properties against S. aureus and E. coli, with the composite containing 5 wt.% of clove filler demonstrating the highest antimicrobial activity. The PUR composite foams also demonstrated a robust fungicidal activity, which indicated their effectiveness as an effective antifungal agent.

Conclusion

To summarize, the use of natural compounds as additives to PURs is an effective strategy to synthesize biocompatible PURs with enhanced antimicrobial and antifungal activity. However, more research is required to explore new natural additives with antimicrobial properties and the feasibility of using them in PURs to improve bactericidal and fungicidal effects.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Sienkiewicz, N., Członka, S. Natural Additives Improving Polyurethane Antimicrobial Activity. Polymers 2022. https://www.mdpi.com/2073-4360/14/13/2533