In an article recently published in the open-access article Polymers, researchers investigated the effect of four factors influencing shear heating on the degradation of polylactic acid (PLA). The PLA was processed and described by its properties of thermal, rheological, and material composition. The team observed that there was no significant contribution to the PLA degradation with an increase in the shear rate and melt temperatures.

Study: Impact of Melt Processing Conditions on the Degradation of Polylactic Acid. Image Credit: icestylecg/Shutterstock.com

Background

The concerning amount of waste generated by non-degradable polymers makes it important to utilize biodegradable and sustainable polymers, such as PLA, reducing the reliance on fossil-fuel-based resources. Although PLA shares similar mechanical properties to those of petroleum-based polymers, its biodegradability makes the melt process challenging.

PLA, a linear aliphatic thermoplastic polyester, is capable of exhibiting high strength and modulus. This could mean that PLA has the potential to substitute conventional polymers in applications such as packaging and consumer goods. However, any thermal load can cause the degradation of the PLA through random chain scission, producing lactic acid and cyclic PLA oligomers. This deteriorates its mechanical properties due to a reduction in molecular weight. In addition, PLA exhibits low ductility and toughness and poor gas barrier properties while bearing high costs.

Rheological measurements such as Fourier-transform infrared radiation (FTIR) and differential scanning calorimetry (DSC) have been used to evaluate the degradation of PLA during melt processing. The team studied PLA degradation based on the parameters affecting shear heating, such as screw speed, extruder type, and feed rate. Subsequently, changes in the melt index, zero-shear viscosity, crystallinity, and the chemical composition of the PLA were used to consider its degradation.

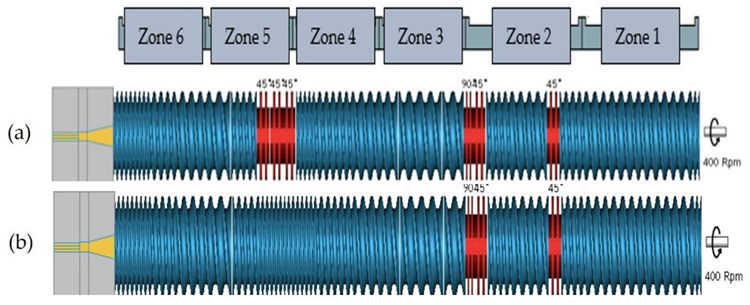

Screws for the TSE and QSE: (a) screw configuration 1 with kneading blocks in the mixing zone (zone 5) and (b) screw configuration 2 with only conveying elements in zone 5. Image Credit: Aldhafeeri, T et al., Polymers

About the Study

In this study, researchers extruded a commercial-grade PLA using a twin-screw extruder (TSE) and a quad screw extruder (QSE). Two trials were conducted with extrusion under a specific set of parameters, and several hours of data were collected.

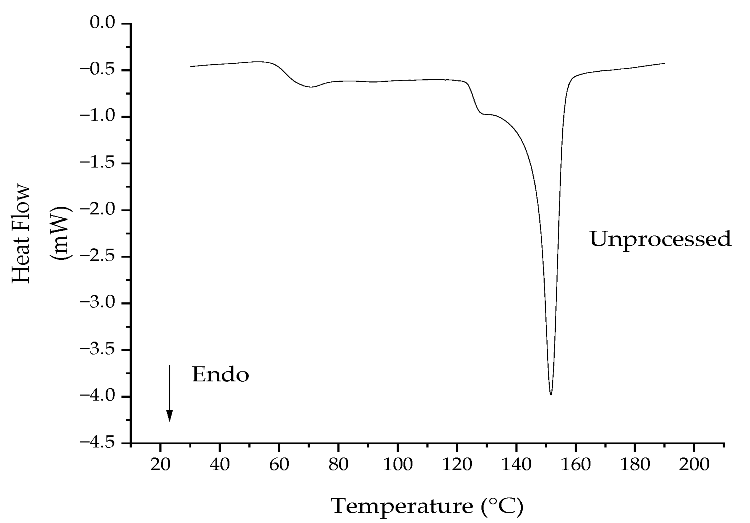

The degradation was evaluated with a parallel plate rheometer performing the dynamic rheological characterization at 180 ºC. The melt flow index (MFI) was measured following ASTM D1238-20, Procedure A, at a 2.16 kg load and 210 ºC. An FTIR spectrometer was used to obtain the FTIR spectra of the processed and the virgin PLA from trials 1 and 2. The thermal performance of the processed PLA was evaluated by DSC.

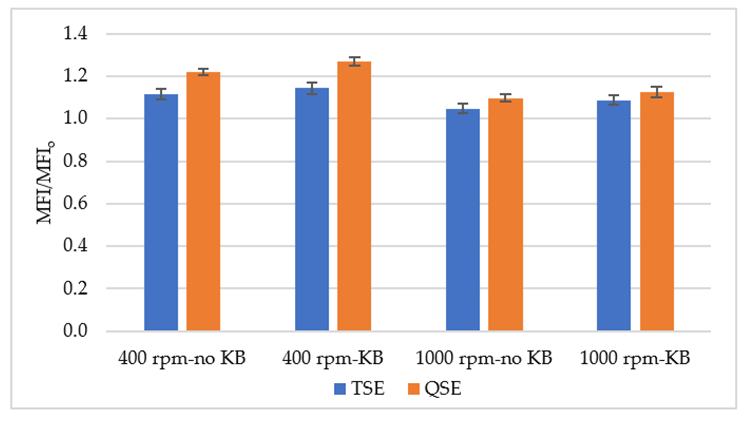

Melt flow index ratio (MFI/MFIo) for polylactic acid, processing the TSE and the QSE at two screw speeds and with two screw configurations. Image Credit: Aldhafeeri, T et al., Polymers

Observations

The team observed that at the speed of 400 rpm, there was only a 4 ºC temperature variance in both the extruders and screw configurations. Furthermore, an increase in screw speed exhibited a decrease in the residence time which was 20% higher for the QSE when compared to TSE. The QSE did not exhibit a substantial increase in the melt temperature with an increase in the feed rate when operated at a 400 rpm screw speed. The residence time decreased linearly.

Moreover, the virgin, as well as the processed PLA, showed a predominant viscous behavior with the loss modulus (G”) being greater than the storage modulus (G’). However, G” and G’ were higher for the TSE than the QSE. The screw configuration or the screw speed did not substantially affect G’ and G”.

Heat flow temperature curve from the first heating cycle of the unprocessed polylactic acid in the DSC. Image Credit: Aldhafeeri, T et al., Polymers

On the other hand, the complex viscosities for the processed PLA were lower than that of the virgin PLA. The processed PLA also exhibited slower relaxation times as compared to the virgin PLA. The molecular weight’s degradation was accredited to longer residence times to shear during extrusion since a negligible increase in the melt temperature was observed in the QSE. Thus, the molecular weight was observed to degrade primarily depending on the residence time, with the temperature being relatively low. Degradation mainly occurred by chain scission as there was no significant variation in the hydroxyl band for the processed PLA. The crystallinity of PLA did not change sufficiently as the residence times of the extruder were not long enough.

Conclusions

To summarize, the researchers assessed the impact of the TSE and the QSE on PLA degradation while the screw configuration and the screw speed constituted compounding parameters. The linear decrease in the molecular weight was attributed to the reduction in MFI and zero-shear viscosity with increasing residence time. However, PLA degradation was reduced by an increase in QSE feed rates, which decreased the residence time.

A major mechanism of the degradation of PLA was chain scission, which increased with prolonged residence times. The PLA crystallinity, however, was unaffected by the reductions in molecular weights.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Aldhafeeri, T.; Alotaibi, M.; Barry, C.F. Impact of Melt Processing Conditions on the Degradation of Polylactic Acid. Polymers 2022, 14, 2790. https://www.mdpi.com/2073-4360/14/14/2790