Cheap and abundant, sodium is a promising candidate for new battery technology. But the limited performance of sodium-ion batteries has hindered their large-scale applications.

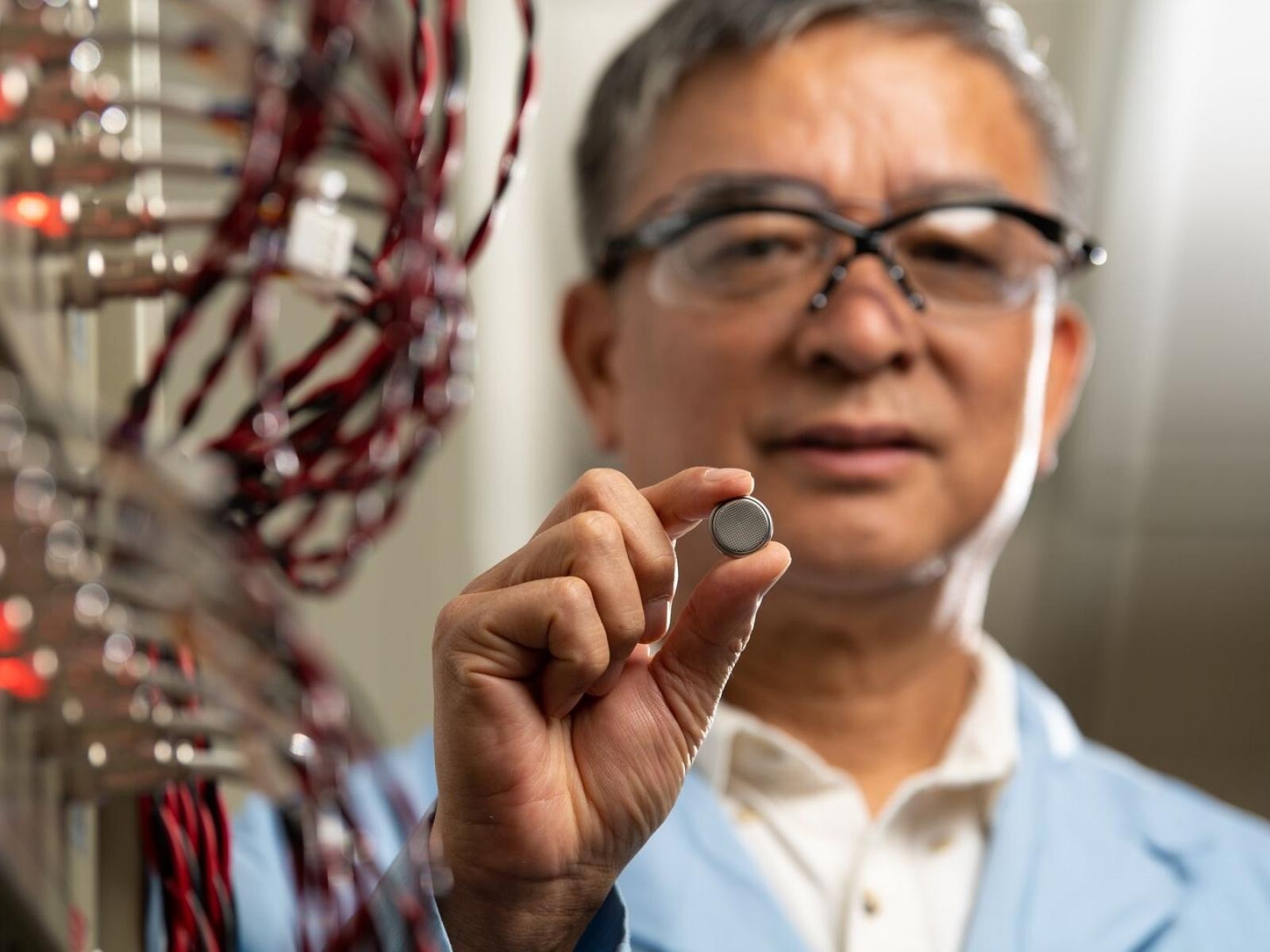

Battery expert Jiguang (Jason) Zhang holds an experimental sodium-ion battery that is more stable and reliable than current sodium-ion battery technology. Image Credit: Andrea Starr | Pacific Northwest National Laboratory

Battery expert Jiguang (Jason) Zhang holds an experimental sodium-ion battery that is more stable and reliable than current sodium-ion battery technology. Image Credit: Andrea Starr | Pacific Northwest National Laboratory

Now, a research team from the Department of Energy’s Pacific Northwest National Laboratory has developed a sodium-ion battery with greatly extended longevity in laboratory tests. An ingenious shift in the ingredients that make up the liquid core of the battery prevents the performance issues that have riddled sodium-based batteries.

The findings, described in the journal Nature Energy, provide a promising recipe for a battery that may power electric vehicles and store energy from the sun in the future.

Here, we have shown in principle that sodium-ion batteries have the potential to be a long-lasting and environmentally friendly battery technology.

Jiguang (Jason) Zhang, Lead Author, Pacific Northwest National Laboratory

Zhang is also a pioneer of battery technologies with more than 23 patented inventions in energy storage technology.

The Right Salt

In batteries, the electrolyte is the circulating “blood” that keeps the energy flowing. The electrolyte forms by dissolving salts in solvents, resulting in charged ions that flow between the positive and negative electrodes.

Over time, the electrochemical reactions that keep the energy flowing get sluggish, and the battery can no longer recharge. In current sodium-ion battery technologies, this process happens much faster than in similar lithium-ion batteries.

The PNNL team, led by scientists Yan Jin and Phung Le, attacked that problem by switching out the liquid solution and the type of salt flowing through it to create a new electrolyte recipe. In laboratory tests, the new design proved durable, holding 90% of its cell capacity after 300 cycles at 4.2 V, which is higher than most sodium-ion batteries previously reported.

The current electrolyte recipe for sodium-ion batteries results in the protective film on the negative end (the anode) dissolving over time. This film is critical because it allows sodium ions to pass through while preserving battery life.

The PNNL-designed technology works by stabilizing this protective film. The new electrolyte also generates an ultra-thin protective layer on the positive pole (the cathode) that contributes to the additional stability of the entire unit.

Non-Flammable Technology

The new PNNL-developed sodium-ion technology uses a naturally fire-extinguishing solution that is also impervious to temperature changes and can operate at high voltages. One key to this feature is the ultra-thin protective layer that forms on the anode. This ultra-thin layer remains stable once formed, providing the long cycle life reported in the research article.

We also measured the production of gas vapor at the cathode. We found very minimal gas production. This provides new insights to develop stable electrolyte for sodium-ion batteries that may operate at elevated temperatures.

Phung Le, Study Lead Authors and Battery Chemist, Pacific Northwest National Laboratory

For now, sodium-ion technology still lags behind lithium in energy density. But it has its own advantages, such as imperviousness to temperature changes, stability, and long cycle life, which are valuable for applications of certain light-duty electric vehicles and even grid energy storage in the future.

The research team continues to refine its design. Le noted that the team is experimenting with other designs to reduce—and eventually eliminate—the need to include cobalt, which is toxic and expensive if not recovered or recycled.

In addition to Jin, Le, and Zhang, the full PNNL research team included Peiyuan Gao, Yaobin Xu, Biwei Xiao, Mark H. Engelhard, Xia Cao, Thanh D. Vo, Jiangtao Hu, Lirong Zhong, Bethany E. Matthews, Ran Yi, Chongmin Wang, Xiaolin Li, and Jun Liu.

The study was supported by the Department of Energy’s Office of Energy Efficiency and Renewable Energy, Vehicle Technologies Office. Imaging studies were performed at EMSL, the Environmental Molecular Sciences Laboratory, a DOE Office of Science User Facility at PNNL sponsored by the Office of Biological and Environmental Research.