By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Jul 27 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Jul 27 2022In an article recently published in the journal Additive Manufacturing, researchers discussed the hot-wire arc additive manufacture of high strength-ductility Al-Zn-Mg-Cu alloys by strengthening precipitates.

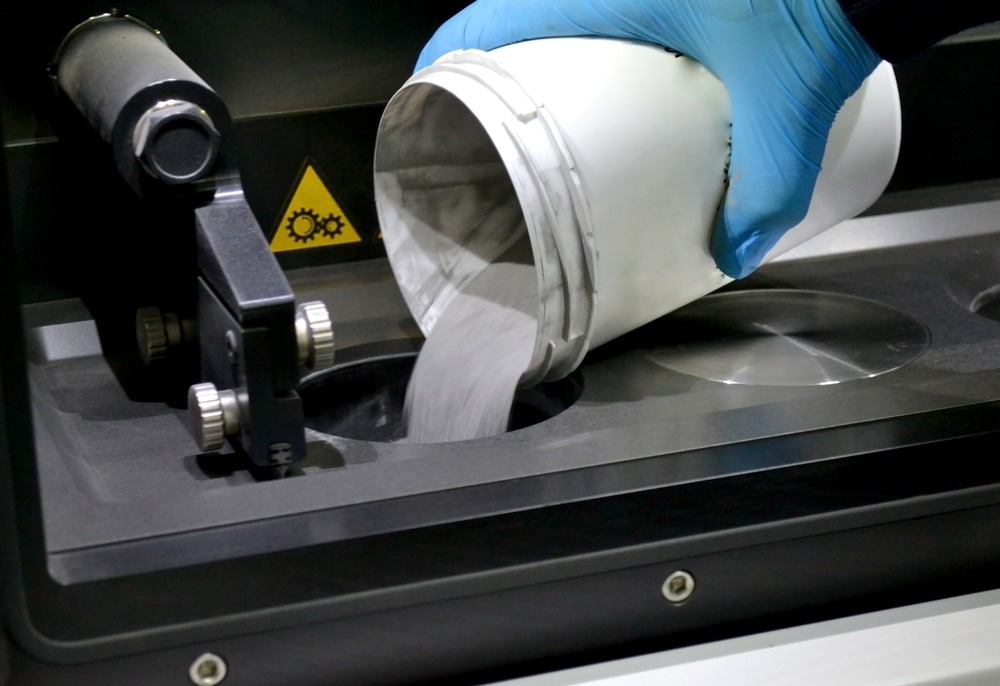

Study: Achieving high strength-ductility of Al-Zn-Mg-Cu alloys via hot-wire arc additive manufacturing enabled by strengthening precipitates. Image Credit: MarinaGrigorivna/Shutterstock.com

Background

Due to their exceptional combination of great fracture toughness, high specific strength, and improved fatigue properties, the Al-Zn-Mg-Cu (7xxx series) alloys are widely employed in the aerospace and military industries. Al-Zn-Mg-Cu alloys are, however, mostly produced using conventional subtractive manufacturing techniques, which have the drawbacks of limited material utilization, expensive processing, and lengthy processing cycles.

Due to its benefits in flexible design and great performance, additive manufacturing (AM) technology has emerged as the new choice for producing metal materials. Due to its high deposition rate, low manufacturing cost, and capacity to produce large-scale components, wire arc additive manufacturing (WAAM), a member of the AM family, has been widely employed in the production of aluminum alloys.

However, Al-Zn-Mg-Cu alloy production using WAAM technology is still in its early stages. Therefore, it is extremely desirable to improve the mechanical properties of WAAM Al-Zn-Mg-Cu alloys. The two most efficient ways to reduce porosity in aluminum alloys with WAAM are to reduce arc heat input and improve wire quality.

However, it is yet unknown how metallurgical flaws in the Al-Zn-Mg-Cu alloys created by WAAM evolve and what impact they have on the mechanical properties. A novel manufacturing technique based on WAAM called hot-wire arc additive manufacturing (HWAAM) allows for the production of products with high levels of overall performance. Studies on the WAAM-fabricated 7055 aluminum alloy's heat treatment procedure, however, are currently insufficient.

About the Study

In this study, the authors investigated the HWAAM technique and suggested a three-stage solution and aging heat treatment approach to further enhance the mechanical properties of the 7055 alloy. The majority of the grains in both the samples taken as-deposited and after heating was equiaxed.

The Mg(Zn,Cu)2 precipitated within the sample's grains as it was being deposited. Al3Zr were also precipitated after heat treatment in addition to the tiny and plentiful Mg(Zn,Cu)2 precipitates. Crack-free 7055 alloy components were produced, and as-deposited and heat-treated samples had low porosities of 0.18 and 0.26 %, respectively.

The team demonstrated that both samples showed alternating clustered-pore zones and discrete-pore zones. After heat treatment, Al-Zn-Mg-Cu alloys had negligible mechanical anisotropy with UTS and elongation of 563 ± 7 MPa and 10.0 ± 1.2 %, respectively. Equiaxed grains, low porosity, and an abundance of strengthening phases were all considered to be responsible for the favorable attributes that reached the wrought level. The ability of AM to create alloys with distinctive microstructures and excellent performance for structural applications was also established.

The researchers discussed two methods. One was to reduce arc heat input and the other to promote the precipitation of strengthening phases to enhance the mechanical properties of a commercial 7055 alloy made by WAAM. In order to limit the heat input during the deposition process of the 7055 aluminum alloy, the hot-wire approach was used.

To adequately precipitate the strengthening phases, a three-stage solution and aging heat treatment was developed. The specimens' microstructures, flaws, and mechanical characteristics were systematically examined both before and after the heat treatment.

Observations

The HWAAM-fabricated 7055 aluminum alloys had pores of 25 µm in diameter. As a result, the low porosity of 0.26 % and small holes were crucial factors in the higher performance of the 7055 aluminum alloys. On the fracture surfaces, there were some dimples; the area fractions of these dimples, as determined by ImageJ software, were 18.5 ± 7.1 % in the longitudinal direction and 17.6 ± 8.4 % in the transverse direction. The porosity in the heat-treated sample increased from 0.18 to 0.26 % in the sample that was deposited as is. The porosity of the heat-treated samples was decreased from 0.26 to 0.18% for the samples left untreated, which demonstrated that heat treatment encouraged the formation of pores.

Due to metallurgical flaws and subpar microstructures, the Al-Zn-Mg-Cu alloys produced by WAAM typically performed poorly. The hot-wire method produced fine microstructures. The majority of the grains in both the heat-treated and as-deposited samples were equiaxed. The as-deposited sample had a significant amount of secondary phases of Mg(Zn,Cu)2 that were unevenly distributed across the grain boundaries.

Mg(Zn,Cu)2 precipitated during the deposition process. Smaller and more numerous Mg(Zn,Cu)2 were precipitated following the heat treatment, and the precipitate-free zone was noticed. Al3Zr was also precipitated in addition. According to the X-ray computed tomography (XCT) data, the faults were mostly related to the pores rather than the cracks. The number of pores increased while the same size was maintained compared to the as-deposited sample. The porosity of the samples taken as-deposited and after heat treatment was 0.18 and 0.26 %, respectively. Due to the remelting and warming, the discrete-pore zone and the clustered-pore zone were alternately permuted in both samples.

After heat treatment, the El percent was 10.0 ± 1.2 %, the YS was 434 ± 6 MPa, and the UTS was 563 ± 7 MPa, which outperformed Al-Zn-Mg-Cu alloys created by WAAM in earlier experiments. In addition, the strength properties showed low anisotropy. The strengthening phases, primarily equiaxed grains, and limited porosity were said to be responsible for the exceptional qualities.

Conclusions

In conclusion, this study elucidated the development of the 7055 aluminum alloy using HWAAM technology, then a three-stage fix was applied, and aging heat treatments were employed to rectify the issue.

In both as-deposited and heat-treated samples, precipitates, grain architectures, flaws, and mechanical properties of the 7055 aluminum alloy were investigated.

More from AZoM: Reflection Electron Microscopy for Crystal Analysis

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Fu, R., Lu, W., Guo, Y., et al. Achieving high strength-ductility of Al-Zn-Mg-Cu alloys via hot-wire arc additive manufacturing enabled by strengthening precipitates. Additive Manufacturing 103042 (2022). https://www.sciencedirect.com/science/article/abs/pii/S2214860422004341