By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Aug 1 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Aug 1 2022In an article recently published in the journal Additive Manufacturing, researchers discussed the creep behavior of an additively manufactured AlSi10Mg alloy through high throughput determination.

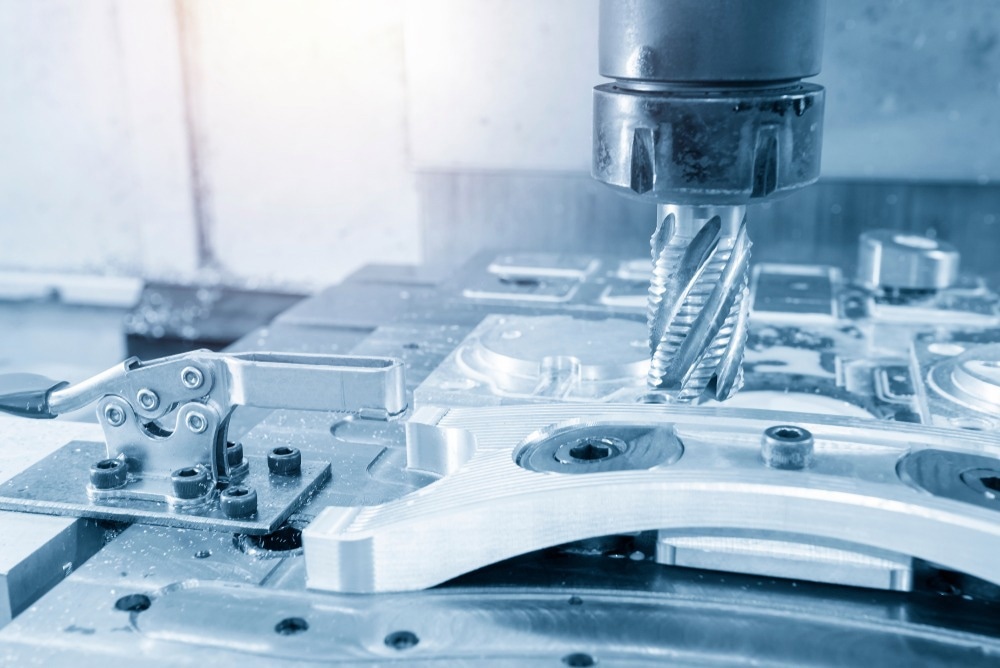

Study: High Throughput Determination of Creep Behavior of Additively Manufactured AlSi10Mg Alloy. Image Credit: Pixel B/Shutterstock.com

Background

Over the past two decades, additive manufacturing (AM) of metals and alloys has grown in popularity and is expanding quickly in terms of research and development, especially in the aerospace industry. The most researched and adaptable method for exact near net form geometry among the different metal additive manufacturing techniques is laser powder bed fusion (LPBF).

The hypoeutectic Al alloy AlSi10Mg has been thoroughly investigated utilizing LPBF. The majority of studies concentrate on somewhat high-stress environments that are close to or entirely within the power-law breakdown (PLB) environment. Studies on creep behavior under low stress, which is more similar to the service state, are scarce.

To comprehend the underlying mechanism of creep, it is essential to critically assess the creep response of the AlSi10Mg alloy in the conventional power-law regime and look into the structure-property relationship. Using sub-ASTM-sized samples from a small number of tests, cantilever bending seems to be an appropriate technique to assess the creep behavior of AM alloys.

About the Study

In this study, the authors assessed the power-law creep behavior of an AlSi10Mg alloy produced by LPBF at 250 °C under uniaxial and bending test circumstances. The cantilever samples were examined utilizing digital image correlation (DIC)-augmented-bending test methods, which was a way of determining creep parameters in a high throughput manner using relatively smaller specimens. Uniaxial tests were carried out in both tension and compression. The applied normal stress was along the transverse direction relative to the construction direction in each test circumstance. Under the steady-state and minimal creep rates, the alloy's creep response displayed tension-compression symmetry.

The team demonstrated that combined uniaxial and high throughput bending creep tests provided excellent correlations, which proved that bending creep tests could be used to assess creep behavior in additively built Al alloys. The durability of the microstructure during extended exposures up to 500 hours during uniaxial creep and the pinning of dislocations by intra-granular Si particles of 20–50 nm size were both demonstrated by detailed electron microscopy of the creep specimens. The links between the structures and properties were covered in great detail.

The researchers combined the microstructural evolution during high-temperature deformation with a systematic examination of the creep behavior of LPBF AlSi10Mg utilizing both traditional uniaxial and DIC-augmented-bending creep test approaches. The goal of this study was to establish small-scale bending creep as a workable benchmark.

Observations

The gauge segment revealed both additional precipitation and a notable coarsening of the precipitation at 250 °C. Diffusivity was calculated to be 1.14 x 10-18 m-2/s, and temperature-corrected shear modulus was 22.4 GPa. The range of stresses was 90 to 115 MPa. The beam's compression side and tension side both experienced a maximum strain of 5%. For the sample tested at 90 MPa, an ever-declining strain rate was seen. An ever-decreasing strain rate was seen for the sample tested at 140 MPa, which achieved saturation at around 7 x 10-6 s-1. The sample tested at 120 MPa demonstrated strain rate saturation.

The uniaxial creep demonstrated a reasonable fit with the creep data retrieved using DIC in bending creep, or DIC-augmented-bending creep. The three tensile and four compression creep tests were completed in 850 hours. But three DIC-augmented-bending creep tests that were completed in 88 hours produced a much higher amount of data in a single test.

Conclusions

In conclusion, this study elucidated the creep behavior of the AlSi10Mg alloy produced using additive manufacturing under uniaxial and bending circumstances.

With the help of precipitation strengthening, detailed correlations to the microstructural creep behavior using transmission electron microscopy (TEM) revealed that Si particles pinning dislocations were the primary factor in the additively manufactured AlSiMg alloy's strength and stability at 250 °C, providing insight into creep deformation mechanism in the prepared LPBF alloy. It was determined that bending creep is a potent high-throughput testing method for additively manufactured materials. The authors mentioned that it will be helpful in establishing the correlation between bending and uniaxial testing as a starting point, in a bulk AM material and enable the correlation of any differences that could arise in samples having defects and anisotropy in the mechanical behavior.

The authors also stated that the ability to validate and facilitate the transfer from small-scale testing using the bending creep approach to engineering alloys, particularly in the context of additive manufacturing, is a crucial component of this study.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Singh, S. P., Jayaram, V., Srinivasan, D., et al. (2022) High Throughput Determination of Creep Behavior of Additively Manufactured AlSi10Mg Alloy. Additive Manufacturing 103049. https://www.sciencedirect.com/science/article/abs/pii/S2214860422004419