Wearable technology, such as virtual reality headsets and fitness and health monitors, is a part of our everyday lives. But it is hard to find a method that will constantly power this technology.

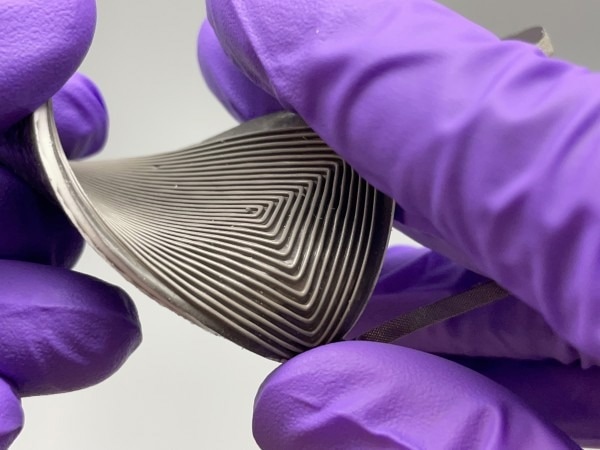

University of Washington researchers have created the first-of-its kind flexible, wearable thermoelectric device that converts body heat to electricity. This device is soft and stretchable, yet sturdy and efficient — properties that can be challenging to combine. Image Credit: Han et al./Advanced Energy Materials

University of Washington researchers have created the first-of-its kind flexible, wearable thermoelectric device that converts body heat to electricity. This device is soft and stretchable, yet sturdy and efficient — properties that can be challenging to combine. Image Credit: Han et al./Advanced Energy Materials

Researchers at the University of Washington have created a revolutionary remedy: the first-ever flexible, wearable thermoelectric device that generates power from body heat. This device is stretchable and soft, yet efficient and sturdy — properties that tend to be challenging to combine.

These findings were published by the researchers on July 24th, 2022, in the journal of Advanced Energy Materials.

It is a 100% gain if we harvest thermal energy that would otherwise be wasted to the surroundings. Because we want to use that energy for self-powered electronics, a higher power density is needed.

Mohammad Malakooti, Assistant Professor, Mechanical Engineering, University of Washington

He added, “We leverage additive manufacturing to fabricate stretchable electronics, increase their efficiency and enable their seamless integration into wearables while answering fundamental research questions.”

The researchers’ prototype device still functions flawlessly after more than 15,000 stretching cycles at 30% strain, which is an extremely desirable quality for wearable electronics and soft robotics. Furthermore, the device’s power density is 6.5 times higher than that of previous stretchable thermoelectric generators.

The researchers used composites that had been 3D printed with customized functional and structural qualities at each layer to make these flexible devices. Liquid metal alloys, which offer high electrical and thermal conductivity, were included in the filler material.

These alloys overcome the shortcomings of earlier devices, such as their inability to stretch, ineffective heat transmission, and difficult manufacturing procedures.

To focus heat on the semiconductors at the core layer and lighten the device, the scientists also added hollow microspheres.

The fact that the researchers were able to print these devices on curved surfaces and flexible textile materials implies that future devices could be employed to make garments and other items. The team is enthusiastic about the true potential of wearable electronics and their practical uses in the future.

Malakooti added, “One unique aspect of our research is that it covers the whole spectrum, all the way from material synthesis to device fabrication and characterization. This gives us the freedom to design new materials, engineer every step in the process, and be creative.”

Malakooti is also a researcher at the university’s Institute for Nano-Engineered Systems.

The lead author of the study was mechanical engineering master’s student Youngshang Han from the UW. In addition, Leif-Erik Simonsen contributed to the study.

Journal Reference:

Han, Y., et al. (2022) Printing Liquid Metal Elastomer Composites for High-Performance Stretchable Thermoelectric Generators. Advanced Energy Materials. doi:10.1002/aenm.202201413.