Scientists from Spain have investigated different strategies for halting aging in polylactic acid (PLA) during freezing and defrosting processes and the consequent effects on material properties. The results of their research have been published in a new paper which has appeared in the journal Polymers.

Study: Natural Ageing of PLA Filaments, Can It Be Frozen? Image Credit: Alex_Traksel/Shutterstock.com

Printing Polylactic Acid

Polylactic acid (PLA) is a polymeric material that is widely used in additive manufacturing, also known as 3D printing. Material extrusion processes are used to print this material to produce tailored structures and devices. There are three main parts to the extrusion process, namely melting, extrusion, and cooling stages.

In the melting process, PLA is liquefied, which removes the material’s previous thermal history, although thermal degradation can occur. During the extrusion process, PLA filaments flow through the printer’s nozzle and are printed with the requisite dimensions. These extruded filaments then undergo cooling wherein they are solidified layer by layer to build the desired product.

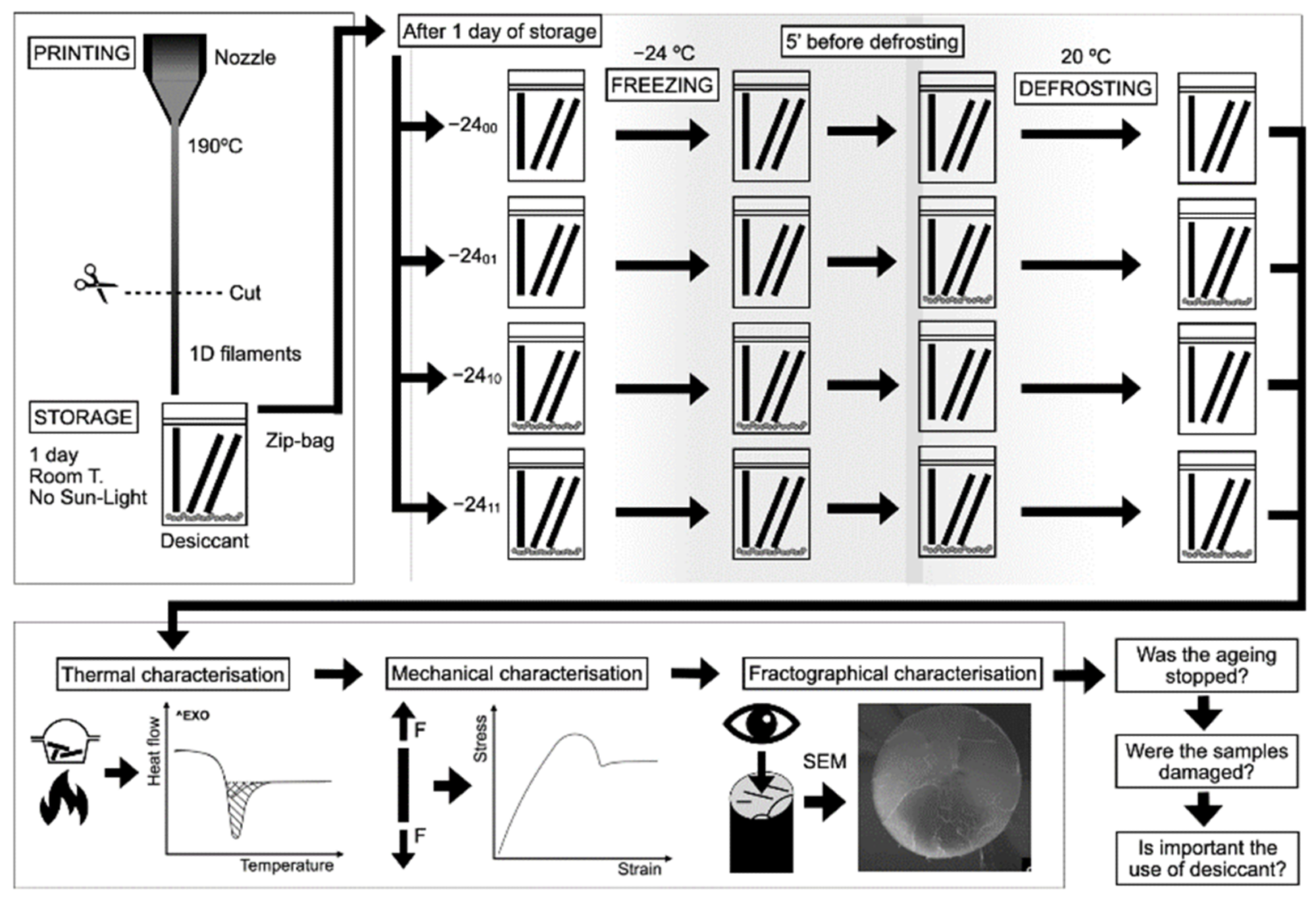

Summary of the materials and methods: material preparation, anti-aging process, thermal, mechanical and fractographical analysis. Image Credit: Orellana-Barrasa, J., et al., Polymers

Problems with Cooling Processes and Printed PLA

Critical issues can occur during the cooling process, which can severely affect the mechanical properties, quality, and durability of the finished printed product. This is due to the generation of an out-of-equilibrium microstructure within the printed material. Polymer chains in the amorphous chain are immobilized in non-equilibrium positions.

Compared to the material’s stable state, the positions of the polymer chains in this state possess high enthalpy values. Aging then causes a loss of excess enthalpy due to the polymeric chains reverting to lower energy configurations.

Several aging mechanisms have been observed in printed and cooled PLA, including hydrolysis and photodegradation. Physical aging (also known as natural aging) occurs due to macromolecular changes in the material. Polymer chains in PLA rearrange into more stable configurations slowly over time after the cooling process.

Physical aging affects the material’s properties, such as yield strength, glass transition, and enthalpic relaxation. Aging occurs at temperatures below the material’s glass transition temperature, but they occur much more rapidly when the material’s temperature is closer to its glass transition temperature. The glass transition temperature for PLA is between 50 and 63 oC.

Due to its glass transition temperature being fairly close to normal ambient temperature ranges and room temperature, it is critical to understand the effects of natural aging on printed and cooled PLA. Moreover, it is crucial to understand how to stop this aging process or slow it down to ensure the quality and durability of printed products.

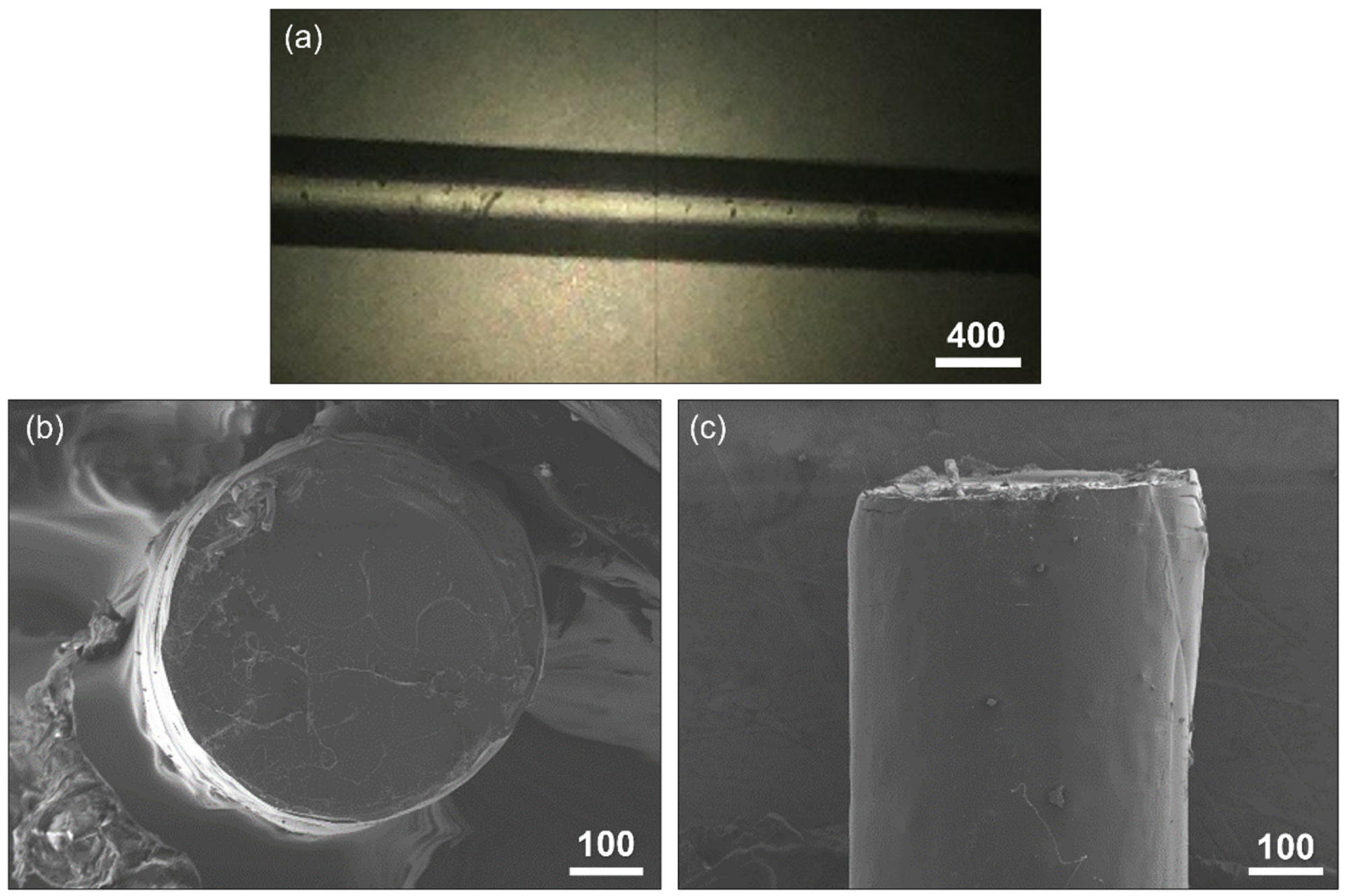

(a) Detail of the PLA filament with the profilometer. (b) Fractography of the filament with the SEM in which the excellent ovality can be observed. (c) Transversal view of the same broken filament. Scale bars in microns. Image Credit: Orellana-Barrasa, J., et al., Polymers

The Study

The authors have sought to understand the mechanisms which lead to physical aging and investigate the potential of freezing PLA to stop this process. Freezing and storing PLA provides benefits for research in the case of external factors such as pandemics which would otherwise slow down the pace of research and, therefore, would see medical materials and devices being wasted due to aging.

As one of the main aging mechanisms is hydrolysis, the authors evaluated the incorporation of desiccants during the anti-aging process. Whilst the experiments were conducted at below 50 oC and in dry conditions (thereby negating the influence of humidity on samples), the authors have stated that the aim is to analyze the effects of humidity on material properties during freezing, which will help mitigate or stop aging.

Four different freezing and defrosting methods were evaluated in the research at different temperatures and either frozen or defrosted with desiccants. Thermal analysis was performed using differential scanning calorimetry. Mechanical testing was performed using a universal testing machine after samples were defrosted for one hour at room temperature to obtain mechanical characterization and fractography data.

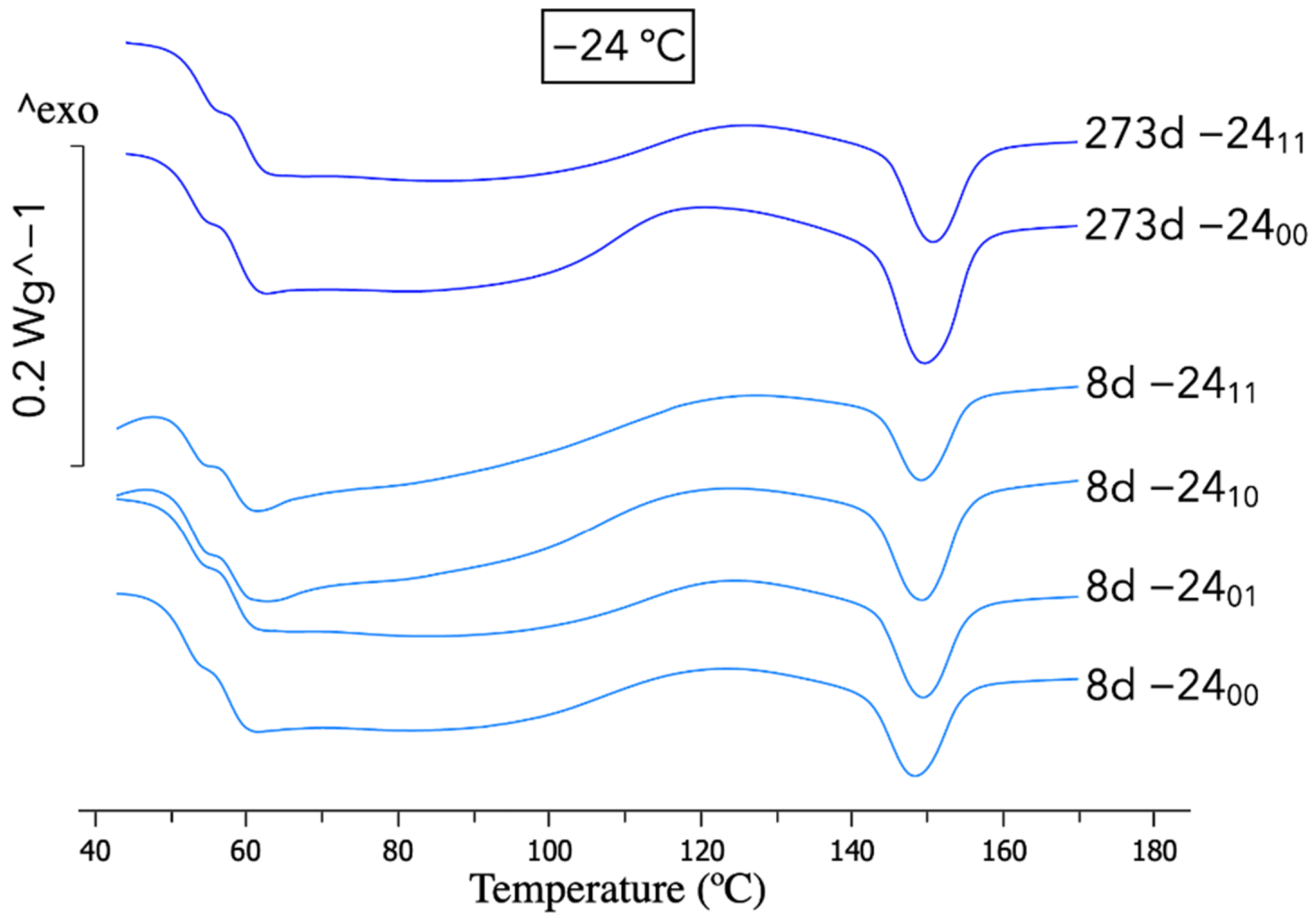

DSC graphs for samples aged at −24 °C following the nomenclature in Table 1. Image Credit: Orellana-Barrasa, J., et al., Polymers

Study Conclusions

The study demonstrates that PLA aging can be stopped by freezing the material below -24 oC for up to nine months. It is possible to continue this process for an indeterminate period of time with the same results.

Importantly, freezing the material at this temperature causes no damage to the material. Furthermore, storing the material within zip bags negates the need for desiccants, making it possible to simplify the anti-aging process and reduce costs. Results indicated that there is no measurable difference in the final state, behaviors, and properties of PLA either with or without the addition of desiccants.

Overall, this study has demonstrated a simple, cost-effective, and efficient method for storing PLA and preserving the mechanical properties of the material and, therefore, the quality of final products by stopping the physical aging process. This will improve fields in which this material is used, especially the biomedical field, which uses PLA for applications such as medical prostheses.

Further Reading

Orellana-Barrasa, J., et al. (2022) Natural Ageing of PLA Filaments, Can It Be Frozen? Polymers 14(16) 3361 [online] mdpi.com. Available at: https://www.mdpi.com/2073-4360/14/16/3361

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.