A new paper published online in the journal Materials has evaluated the performance of concretes incorporating rubber from waste tires and recycled tire steel fibers. The research has been conducted by scientists from Cyprus and the UK.

Study: Concrete with a High Content of End-of-Life Tire Materials for Flexural Strengthening of Reinforced Concrete Structures. Image Credit: Bonita R. Cheshier/Shutterstock.com

Replacing Aggregates in Concrete with Waste Materials

Concrete manufacture is a main contributor to carbon dioxide emissions, and rapidly accelerating global urban development and infrastructure is increasing the need for this environmentally damaging material.

To address the issues faced by the construction industry and human society, valorizing abundant waste materials to replace aggregates and ordinary Portland cement in concrete has emerged as a viable field of research in recent years.

Several industrial waste streams have been investigated for their benefits for the construction industry as material substitutions in concrete. Fly ash, foundry slag, ornamental stone, and recycled demolition waste have been explored, bringing benefits in terms of sustainability, cost-effectiveness, environmental friendliness, circularity, waste reduction, and mechanical and physicochemical property improvements.

Four-point bending test setup. Image Credit: Polydorou, T., et al., Materials

Rubberized Concrete

A potential material which could be widely employed for replacing aggregates in sustainable concretes is rubber. Research has indicated that incorporating rubber particles can have the benefit of improving concrete’s energy absorption capacity.

However, incorporating high volumes of rubber particles can cause technical challenges. Rubber can significantly reduce the compressive strength of concrete, which has led to researchers cautioning against incorporating these high volumes of materials. Studies have indicated that rubber particles can enhance particular concrete mechanical properties, and can provide enhanced performance under earthquake and impact loading.

Utilizing Waste Tires

Using waste streams to provide rubber for rubberized concrete is in line with the aims of the circular economy, reducing the amount of waste typically sent to landfills or disposed of in the environment. Over one billion end-of-life tires, a key source of waste rubber, are generated every year. This presents a significant environmental challenge.

Tires have a complex chemical composition, as well as steel fibers, which makes them challenging to recycle with conventional means. Chemical components can be converted into biofuels, and recently research has focused on using waste rubber particles and steel fibers as concrete aggregate replacements and reinforcing elements for concrete.

Waste steel fibers can improve properties such as the flexural strength of concrete, along with enhancing energy absorption when used in conjunction with rubber particles. Several uses for novel fiber reinforced concretes have already been presented in the literature, with their incorporation in reinforced concrete applications such as bridges and beams providing improved structural strength.

Research has indicted that recycled steel fibers from tires are an effective concrete reinforcement, possessing comparable or even superior mechanical properties and performance than manufactured steel fibers. Multiple studies have investigated the use of various quantities of recycled waste tire rubber particles and steel fibers and their ability to enhance concrete mechanical properties.

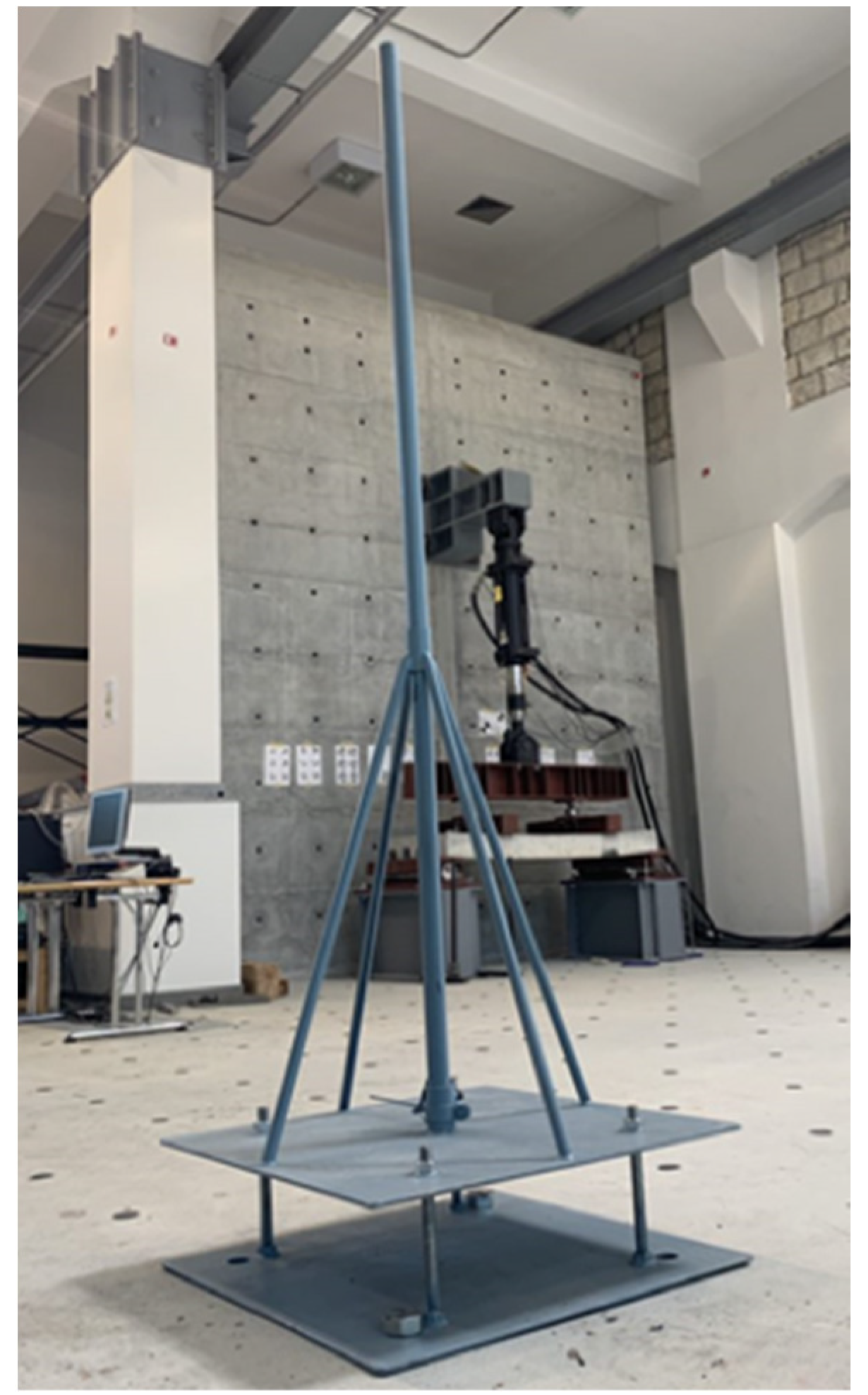

Impact test drop-weight frame. Image Credit: Polydorou, T., et al., Materials

The Study

Thus far, only one study has investigated the performance of PVA fiber-reinforced rubberized cementitious composites. The potential of reinforced rubberized composites to replace conventional aggregates and provide performance enhancements is promising.

The new study has aimed to evaluate the performance enhancements of concrete incorporating large volumes of rubber particles and recycled steel fibers obtained from end-of-life tire waste. The authors studied the effects of replacing 60% of conventional concrete aggregates with rubber particles. The environmentally friendly concrete produced in the research has been termed Steel Fiber Reinforced Rubberized Concrete.

Mechanical properties and durability were investigated in the research. Several tests were conducted, including cyclic and static loading, impact loading, flexural bending, and durability tests. Durability tests were performed under environmental conditions, specifically freeze-thaw cycles and chloride exposure. Numerical analysis of the obtained experimental data was employed, enabling comparison with conventional strengthening techniques.

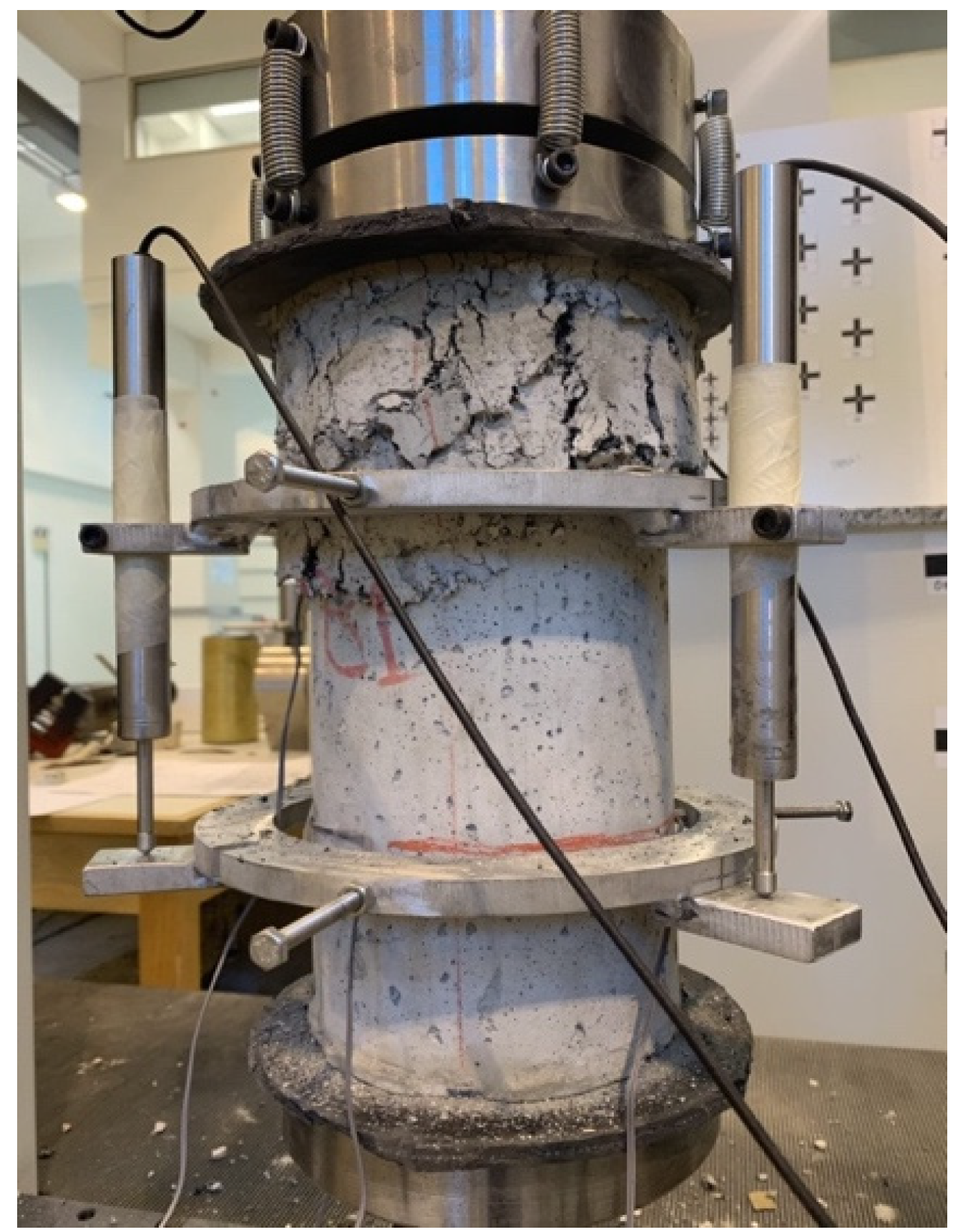

Cyclic Compressive Loading Specimen B1 at 20 mm Displacement. Image Credit: Polydorou, T., et al., Materials

Study Findings

Using these waste materials provides benefits in terms of sustainability and circularity because of the large amounts of recycled end-of-life materials. Additionally, the concrete produced attains excellent strain capacity and is promising for sustaining cyclic loading. Despite having a low compressive strength, the material withstands long-lasting cycling loads, making it a promising structural material.

A vastly improved damping ratio was observed by incorporating high volumes of rubber particles, which has a positive impact on the energy absorption capacity of this novel steel fiber-reinforced rubberized concrete. Additionally, the material possesses ample durability in corrosive environments and under freeze-thaw cycles.

Numerical assessment revealed that the material can enhance the performance of structural elements manufactured from reinforced concrete compared to conventional reinforcement strategies. Whilst this is a largely unexplored area of sustainable concrete research, the study provides promising perspectives on steel fiber-reinforce rubberized concrete, which has benefits in terms of sustainability and performance enhancements.

Future research directions have been identified by the authors, such as retrofitting existing structures with this novel material and applying them in seismic isolation foundation systems. Future research will enable the industrial-scale application of these materials in structural engineering and construction elements.

Further Reading

Polydorou, T., et al. (2022) Concrete with a High Content of End-of-Life Tire Materials for Flexural Strengthening of Reinforced Concrete Structures Materials, 15(17), p. 6150 [online] mdpi.com. Available at: https://www.mdpi.com/1996-1944/15/17/6150

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.