Writing in the journal Materials, a team of researchers from Germany and Canada has investigated the development of hybrid multifunctional fiber composites for efficient electrical energy transfer and lightweight electrical propulsion systems.

Study: Multifunctional Hybrid Fiber Composites for Energy Transfer in Future Electric Vehicles. Image Credit: guteksk7/Shutterstock.com

Electric Transportation: A Key 21st Century Technological Trend

The environmentally damaging effect of humanity’s exploitation of vast amounts of fossil fuel resources to meet energy and transportation demands has become clearer over the past few decades.

Electric vehicles are a growth industry, with several automotive companies introducing fully electric models in the past decade. Moreover, current pledges to reduce carbon emissions to net zero have seen governments aim to phase out the sale of new ICE vehicles over the next decade or two in favor of electric models.

Electric propulsion has been explored extensively for multiple classes of vehicles, including family cars, heavy goods vehicles, trains, and airplanes. However, there are several technical challenges that must be met for electric propulsion systems to provide the same performance and efficiency as conventional ICE vehicles, with heavy good vehicles, trains, and airplanes in particular requiring systems that can deliver superior powertrain performance.

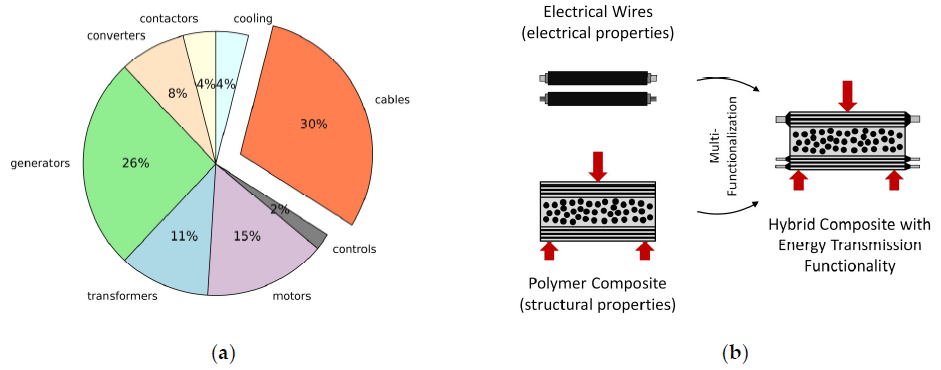

(a) Electrical system weight of an electric 300-seater aircraft, according to Gohardani et al.; (b) concept of multifunctional electrically conductive and load-bearing (red arrows) composites for transferring energy from storage to electrical consumers. Image Credit: Adam, T.J et al., Materials

Optimizing Electric Propulsion Systems with Multifunctional Materials

Optimizing propulsion systems is vital for ensuring their efficient performance that can meet the power demands of this new generation of transportation. Optimizing components is a widespread technological approach employed by scientists and manufacturers. Beyond this component optimization, the design of efficient multifunctional materials has become a key research trend in recent years.

Amongst multifunctional materials, energy-storing composite materials have been explored in recent research. These materials can help to realize efficient and energy-saving airplanes and road vehicles. A key challenge associated with these materials and their use in components is designing them to deliver high electrical energies to meet the needs of vehicle systems and decrease the mass of components.

To decrease cable mass, the main strategy is to increase operating voltage. If the voltage is increased to 2000 V, only 200 kg of cables are needed. This approach works for the main power transmission lines, but state-of-the-art airliners also have a mass of electrical cables for multiple systems, and this strategy may be insufficient for these types of cabling. In a fully electric airliner with three hundred seats, cabling can account for 30% of the electrical system's total mass.

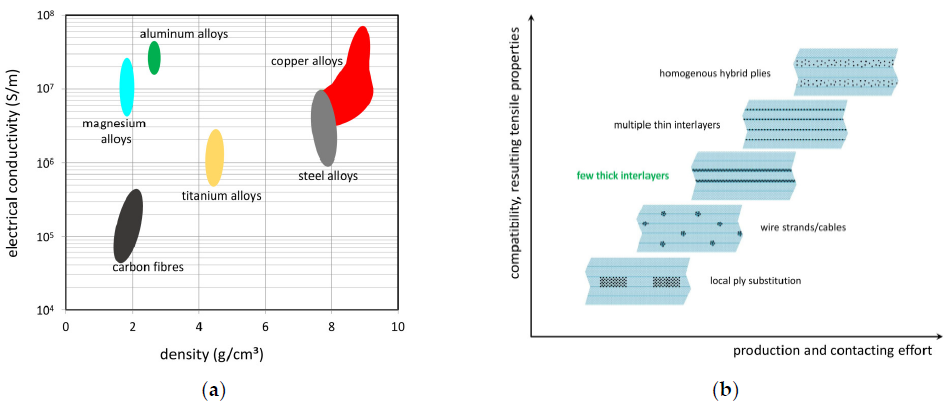

Multifunctional conductive hybrid materials incorporating metal phases have been proposed as a potential solution to the critical technical challenges for all-electric transportation. Hybrid composites incorporating carbon-based nanomaterials and polymers suffer from low conductivity due to the high resistivity of carbon and insulation properties of polymer matrices.

One approach in current studies is to integrate micro-scaled continuous metal fibers. These fibers have a diameter of less than 100 µm. However, high volume fractions are necessary, which causes issues with mass increases. A more efficient, lightweight material strategy is needed to help these multifunctional materials become commercially viable for the future of electric transportation.

(a) Electrical conductivities and densities of carbon and metal fiber candidates; (b) different approaches to metal fiber integration. Image Credit: Adam, T.J et al., Materials

The Paper

To overcome this critical issue, the team has developed and evaluated a novel lightweight and efficient multifunctional hybrid composite incorporating glass and aluminum fibers.

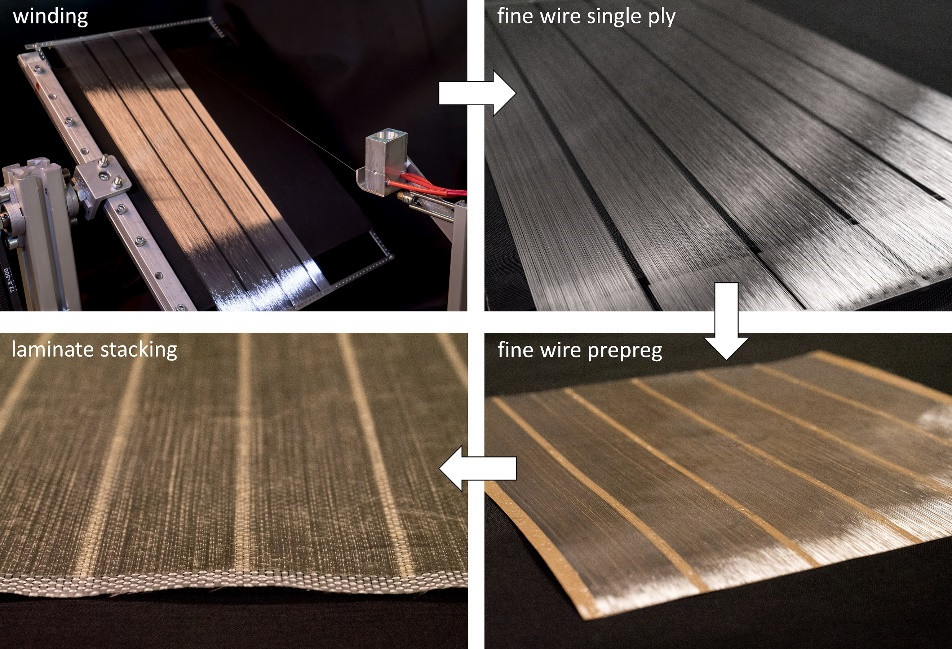

The composite material combines unidirectional aluminum fiber prepregs and unidirectional glass-fiber weave fabrics. Composites were prepared using winding techniques. Material performance of reference samples which do not contain aluminum and samples containing aluminum in three different proportions were assessed for performance.

Performance was measured in terms of different mechanical and electrical loads. Various techniques were employed for assessing the samples, including potentiometry, thermography, and microscopy. The authors characterized the mechanical properties of the multifunctional composite materials.

The stated main objectives of the paper are four-fold. Firstly, the material’s mechanical performance for both fatigue and static loads was evaluated. Secondly, the research aims to demonstrate that the composite can carry technically relevant charges without affecting its mechanical properties.

Thirdly, the paper aims to generate a deeper understanding of damage mechanisms under mechanical and electrical loads. Finally, the study discusses the capabilities of the proposed multifunctional hybrid material and its technical potential. Thus, the research provides valuable information for the future development of electrical propulsion systems and electric vehicles and a route toward a new generation of electric conductors.

Steps of the aluminum fiber integration. Image Credit: Adam, T.J et al., Materials

Study Findings

The study makes some important conclusions. Firstly, fatigue and tensile strength in the parallel direction are not negatively impacted by a 10% aluminum integration by volume. Transverse strength, however, is significantly reduced. Improved surface treatments could improve this. Electrical conductivity is maintained until the specimen is ruptured under static loads but decreases under cyclic loads.

Currents of 320 mA/mm2 can be carried by the composite material. However, there is a negative effect on fatigue life at low load levels. A fundamental problem that needs to be addressed is thin aluminum fiber contacting. This is especially relevant in approaches that integrate finer fibers.

A further issue with the research is the low voltages used. Real-world electric vehicles require higher energy transfer, so further studies need to be performed on high voltages and currents. Furthermore, future research is needed on industrial fabrication, reliable and durable contactor design, electrical system integration, and questions of repairability and safety.

Further Reading

Adam, T.J, Wierach, P & Mertiny, P (2022) Multifunctional Hybrid Fiber Composites for Energy Transfer in Future Electric Vehicles Materials 15(18) 6257 [online] mdpi.com. Available at: https://www.mdpi.com/1996-1944/15/18

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.