Reviewed by Mila PereraSep 16 2022

In recent years, interest in organic solar cells (OSCs), which employ organic polymers to transform sunlight into electricity, has grown significantly due to their potential as next-generation energy sources. They include a high-power conversion efficiency, adaptability, lightweight, and scalability.

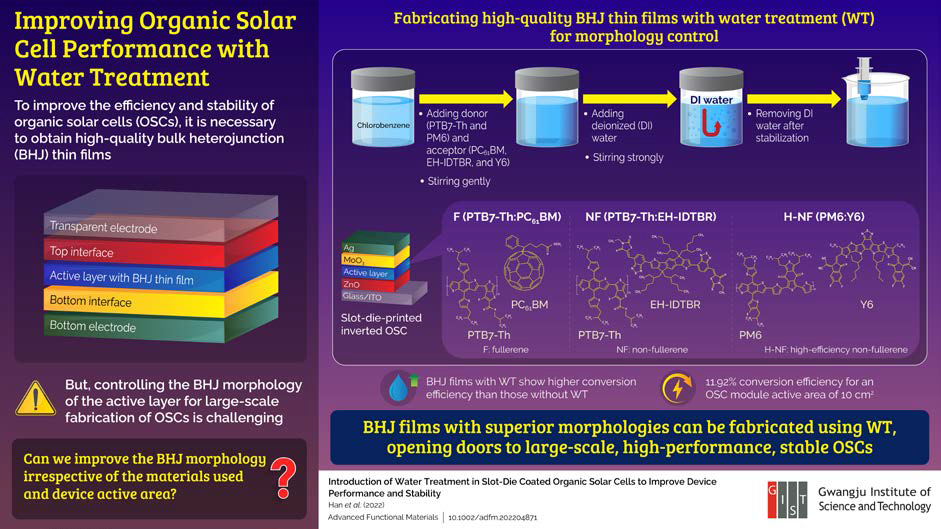

Organic solar cells (OSCs) exhibit many desirable properties, including a high conversion efficiency and easy scalability. However, controlling the morphology of the active layer thin film during upscaling has proved challenging. In a new study, GIST researchers solve this problem with deionized water as a method for morphology control, enabling high efficiency OSC modules with large active areas. Image Credit: Dong-Yu Kim from Gwangju Institute of Science and Technology

Organic solar cells (OSCs) exhibit many desirable properties, including a high conversion efficiency and easy scalability. However, controlling the morphology of the active layer thin film during upscaling has proved challenging. In a new study, GIST researchers solve this problem with deionized water as a method for morphology control, enabling high efficiency OSC modules with large active areas. Image Credit: Dong-Yu Kim from Gwangju Institute of Science and Technology

There are now many methods for improving OSC performance and stability. However, the difficulty of controlling the morphology of the active layer in OSCs when scaling up to huge areas continues to be challenging.

It is difficult to obtain high-quality active layer thin films as a result, which makes it challenging to optimize device efficiency.

A group of scientists from the Gwangju Institute of Science and Technology in Korea carried out research to address this issue.

They proposed a method that initially appears counterintuitive: employing water treatment to alter the active layer shape. The study was published in the journal Advanced Functional Materials.

Water is known to hinder the performance of organic electronic devices, since it remains in the ‘trap states’ of the organic material, blocking the charge flow and degrading the device performance. However, we figured that using water rather than an organic solvent-based active solution as a medium of treatment method would enable necessary physical changes without causing chemical reactions.

Dong-Yu Kim, Professor, Gwangju Institute of Science and Technology

Professor Kim headed the study.

The polymers PTB7-Th and PM6 were selected by the researchers as donor materials, whereas PC61BM, EH-IDTBR, and Y6 were chosen as acceptor materials for the active layer. They discovered that while creating a vortex in the active solution to mix the donor and acceptor materials could result in a well-mixed active solution, this alone was insufficient.

This active solution was hydrophobic, so the researchers chose to agitate it with deionized (DI) water and vortices. After letting the donor and acceptor materials soak in the host active chlorobenzene solution overnight, they added DI water to the mixture and swirled it to form small vortices.

The water forced the donor and acceptor molecules into the solution due to the mixture's hydrophobic nature, which caused them to disperse more thoroughly. The water separated from the solution after they gave it time to rest.

This water was later discarded and the water-treated active solution was utilized to generate thin films of PTB7-Th: PC61BM (F, fullerene), PTB7-Th: EH-IDTBR (NF, fullerene), and PM6: Y6 (H-NF, high-efficiency non-fullerene).

After that, the authors assessed the thin films’ photovoltaic performance against untreated OSCs in a slot-die-coated inverted OSC configuration.

We observed that the water-treated active solution led to a more uniform active layer thin films, which showed higher power conversion efficiencies compared to those not treated with water. Moreover, we fabricated large-area OSC modules with an active area of 10 cm2, which showed a conversion efficiency as high as 11.92% for water-treated H-NF films.

Dong-Yu Kim, Professor, Gwangju Institute of Science and Technology

Overall, this research offers recommendations for creating big, effective OSCs in a way that is amazingly simple, affordable, and environmentally benign, which may pave the way for their realization and commercialization.

Journal Reference

Han, N., et al. (2022) Introduction of Water Treatment in Slot-Die Coated Organic Solar Cells to Improve Device Performance and Stability. Advanced Functional Materials. doi.org/10.1002/adfm.202204871.