Writing in the journal Micromachines, a team of scientists from Beijing University of Technology and University College Dublin has investigated current perspectives on microinjection molding of polymeric microdevices.

Study: A Review of Microinjection Moulding of Polymeric Micro Devices. Image Credit: Adnan Hidayat P/Shutterstock.com

What are Polymeric Microdevices?

Microdevices have gained research attention in the fields of biomedicine and optics, with progress made in recent years toward mass production and commercialization. Devices can be constructed from several materials such as glass, ceramics, metals, and polymers.

Several innovative applications have been explored for microdevices including drug delivery systems such as microneedles, diagnostic microfluidic devices, medical implants, devices with functional nano/microstructured surfaces, and micro-optics. Devices can be designed with complex microstructures and novel functionalities.

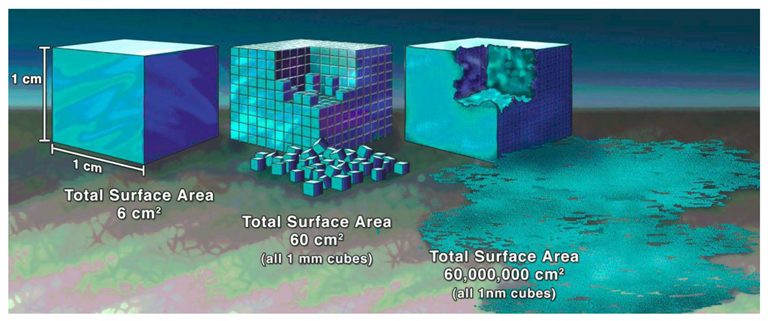

Using polymeric microdevices for nano- and micro-scaled surfaces on devices such as microfluidic chips significantly increases their surface-to-volume ratio, which improves their performance. Significant research progress has been made in recent years in designing polymer microdevices, both as standalone applications and as surface components for other micro-scaled devices.

Comparison of surface areas: a 1 cm3 volume is composed of 1 cm, 1 mm, and 1 nm cubes. Image Credit: Zhang, H et al., Micromachines

Microinjection Molding

Several studies have evaluated manufacturing processes for polymeric microdevices, with microinjection molding emerging as a suitable method. Advances in technology have made it a preferred high-volume manufacturing technique.

The technique was initially developed in the late 1980s, but in the early stages of its development, no appropriate machine technologies were available. Modified conventional injection molding machines with hydraulic drive functions were used to replicate high-aspect-ratio micro-scaled parts. Producing reliable and functional microdevices was highly challenging.

Industrial microinjection molding trials revealed significant issues with using conventional injection molding techniques, including long cycle times, process inconsistencies, material waste, and residence problems. Other problems include the demanding tolerances needed for micro-molded parts and in the case of polymeric microdevices, the untoward modification of their properties and microstructure.

Polymeric micro- and nano-features require high quality and consistent replication to ensure the performance of devices. The critical problems with conventional injection molding techniques have led to a significant research focus on equipment development and parameter optimization techniques. Micro-molding technologies based on reciprocating screws, plungers, and multi-stage systems have been developed over the past twenty years.

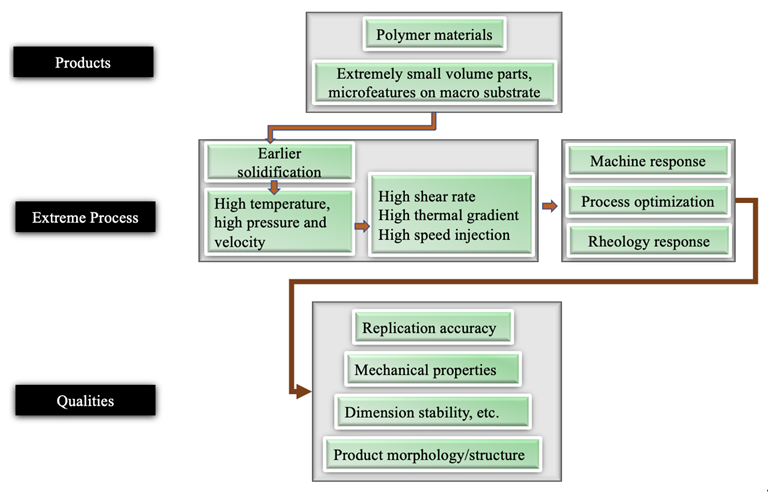

Process-properties relationships overview for microinjection molding. Image Credit: Zhang, H et al., Micromachines

Review Perspectives

Microinjection molding of polymeric microdevices is a field that is still in its relative infancy, but significant advances have been made in recent decades. The paper in Micromachines has provided a review of current state-of-the-art perspectives on the technology and the properties of polymeric microdevices produced using microinjection molding techniques.

Perspectives on equipment, processes, tooling, nano- and micro-scale replication, and applications have been highlighted. Additionally, the rheological properties, mechanical properties, and morphologies of polymeric devices are comprehensively reviewed by the authors.

The recent expansion in applications for polymeric microdevices in areas such as biomedicine, lab-on-a-chip technologies, and micro-optics has inspired research on various perspectives of microinjection molding technologies. Process optimization, machine and mold design, numerical simulations, polymeric microdevice properties, morphologies, rheology, and advanced applications have been explored extensively.

Overall, the review has highlighted the key progress in this field in recent years, and the authors have noted that fundamental development in the field of polymeric microdevice microinjection molding has generated novel micro-scaled devices, vast amounts of process knowledge, and know-how for product development in the future.

Challenges and Future Perspectives

Like any field of technology, however, there are several limitations in this field that must be overcome to ensure mass production and widespread commercial viability of polymeric microdevices produced via microinjection molding methods. The review has highlighted several key challenges.

Firstly, optimizing mold design to replicate high-quality devices with enhanced features and functionalities is a key technical challenge. Reliable, advanced vacuum venting systems and temperature control systems for molds need to be designed.

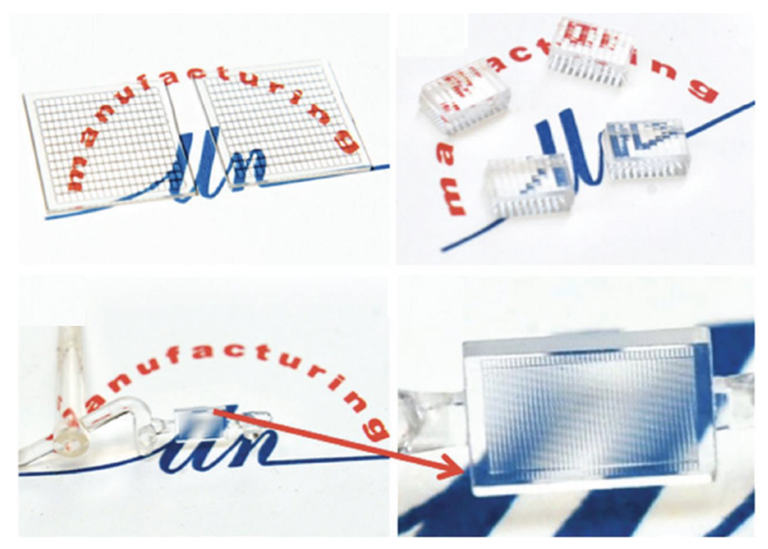

Microinjection molded micro lenes array. Image Credit: Zhang, H et al., Micromachines

Developments in semiconductor fabrication methods could produce larger substrates with nano- and micro-scaled surface features. In current research, the multi-scale fabrication of integrated surface features on metallic substrates and inserts has not been widely reported. Commercial microfluidic devices urgently need research into in-line functionality integration.

Furthermore, studying nano- and micro-scaled surface features produced using microinjection molding processes on large substrates and exploring process optimization routes and quality control will have huge practical value for future research. Quality control and process optimization research will also have use for standalone polymer microdevices.

Finally, optimization of the entire process chain has vast potential for this field, and integrating industry 4.0 technologies can aid the industrial scale mass production of complex microinjection molded polymer microdevices.

In Summary

The review paper has provided a comprehensive knowledge base for future researchers in the field of polymer microdevice design and manufacture. Microinjection molding is playing an increasingly central role in the production of these advanced micro-scaled devices. Whilst several key challenges still exist, huge potential exists for the design of innovative, advanced devices in fields such as biomedicine, optics, and diagnostics.

Further Reading

Zhang, H, Liu, H & Zhang, N (2022) A Review of Microinjection Moulding of Polymeric Micro Devices Micromachines 13 (9) 1530 [online] mdpi.com. Available at: https://www.mdpi.com/2072-666X/13/9/1530

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.