A new paper published in the journal Energies has explored the development of a novel material similar to coal for the simulation of raw resources in protective-seam mining studies. The paper is authored by scientists from the Xi’an University of Science and Technology in China.

Study: Development and Properties of a Similar Material to Coal. Image Credit: xpixel/Shutterstock.com

Coal – A Key Energy Resource

Coal mining and recovery has a long history, and since the Industrial Revolution has provided the energy needs of billions of people worldwide. However, the significant exploitation of this raw material has been linked to anthropogenic climate change, extreme weather events, and land, air, and marine pollution.

Coal, like all other virgin natural resources, is finite. As shallower coal seams are exhausted, the need to recover deeper resource seams has become necessary in the past several decades. However, exploiting these deep resources brings significant safety and technical challenges for mining companies, with risks such as mine collapse and coal and gas outbursts frequently occurring worldwide.

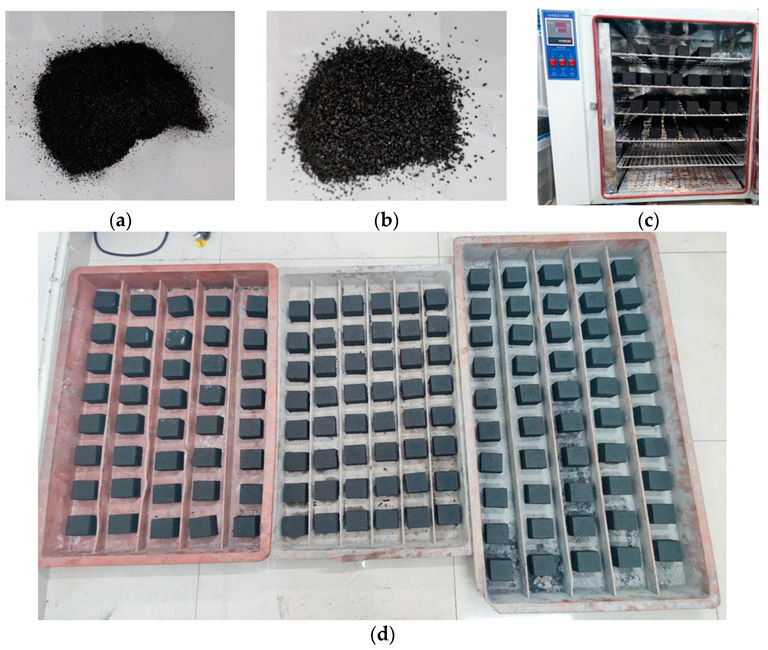

Specimens proportioned using pulverized coal and sodium humate. (a) Pulverized coal; (b) sodium humate; (c) drying oven; (d) and coal briquette specimens. Image Credit: Zhang, K & Xue, J, Energies

Protective-Seam Mining

Protective-seam mining is a technique that can control and prevent gas outbursts from occurring, improving the safety, economic viability, and efficiency of mining operations. This process forms caved zones, fractured zones, and bent subsidence zones in the overlying rock strata, and due to the formation of vertical and transverse fractures, coal-bed gas migrates to the working face.

Gas can be efficiently and safely extracted from the working face by leveraging gas extraction technologies. Methods that can be utilized in protective-seam mining include surface boreholes and goaf gas drainage and extraction. Several laboratory-scale studies have used simulations to explore the development and evolution of fractures.

Coal Analogs – An Innovative Alternative to Natural Coal for Studies

Laboratory studies require materials with similar properties and in situ behavior to natural coal and coal seams, with pioneering research conducted in the 1960s in Japan. One study conducted by Masuyuki et al. explored the development of coal analogs by mixing rosin, cement, and crystalline carbon dioxide with samples of coal. However, this approach could not accurately replicate the chemical and physical properties of natural coal.

Notable progress has been made in recent decades to develop coal analogs from various materials for laboratory-scale studies. Studies have developed several promising materials, but there are still critical challenges in accurately replicating natural coal, such as low strength and differing mechanical and physical properties. Despite progress, materials do not currently adequately meet the test conditions.

Mass of the specimens. Image Credit: Zhang, K & Xue, J, Energies

The Study

The paper has evaluated the performance and properties of a novel material similar to natural coal as an alternative for simulating gas and coal outbursts in real-world conditions. Several orthogonal proportioning tests were employed in the research, and the authors based their experiments on the work of preceding scientists in this research area.

The basic aggregate selected in the research is pulverized coal of a certain size due to the special gas adsorption and desorption properties of natural coal. The fixed ratio of pulverized coal particles was 0~1 mm: 1~3 mm. However, pure briquettes of compressed pulverized coal have low strength, which requires a binder to be incorporated to improve this critical material parameter.

Crucially, the selection of binder needs to guarantee that the simulated material displays similar gas adsorption and desorption behavior whilst not compromising its strength. A solution of water and sodium humate was selected as the binder based on a suite of multiple orthogonal tests. Notably, sodium humate is a coal extractant and possesses beneficial adsorption properties.

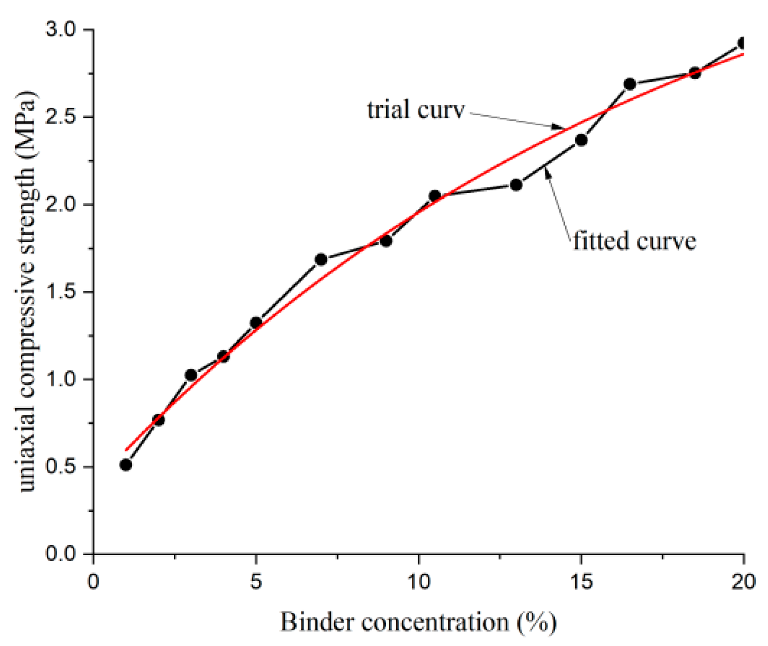

The binder content was optimized to ensure the strength of samples whilst avoiding over-wetting, which has a negative effect on molding quality. Molding water binder content was fixed at eight percent. Multiple briquette specimens with dimensions of 50x50x35mm were prepared for mechanical and physical property evaluation. Samples were both naturally dried and dried in an oven.

Unit weight, porosity, mechanical parameters, and influencing factors that affect the mechanical and physical properties and compressive strength of prepared samples were analyzed and categorized by the authors.

Effects of the binder concentration on the strength. Image Credit: Zhang, K & Xue, J, Energies

Study Findings

Experimental results and analysis of the material’s properties and behavior revealed that it is similar to natural coal. 15 MPa molding pressure produced a material with comparable unit weight and porosity to raw coal. Additionally, the material possesses a regulatable compressive strength and favorable absorptivity.

Benefits of the novel material presented in the research include low cost, stable properties, a lack of toxicity and side effects, and regulation of various mechanical and physical parameters. Based on their observations, the authors have concluded that this novel material can be used to produce coal analogs with a range of strengths in laboratory studies that will benefit coal mining companies.

Further Reading

Zhang, K & Xue, J (2022) Development and Properties of a Similar Material to Coal Energies 15 (19) 6922 [online] mdpi.com. Available at: https://www.mdpi.com/1996-1073/15/19/6922.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.